A 20 hp dc electric motor needs careful preparation to be integrated into an automated system. These strong motors are essential to modern industrial automation due to their ability to precisely manage speed and consistently produce torque. Several industrial applications could benefit from a 20 hp dc electric motor that is equipped with variable speed drives and the appropriate controllers. Knowing your motor specifications, load requirements, and system compatibility inside and out is crucial for optimizing your automation setup for maximum performance.

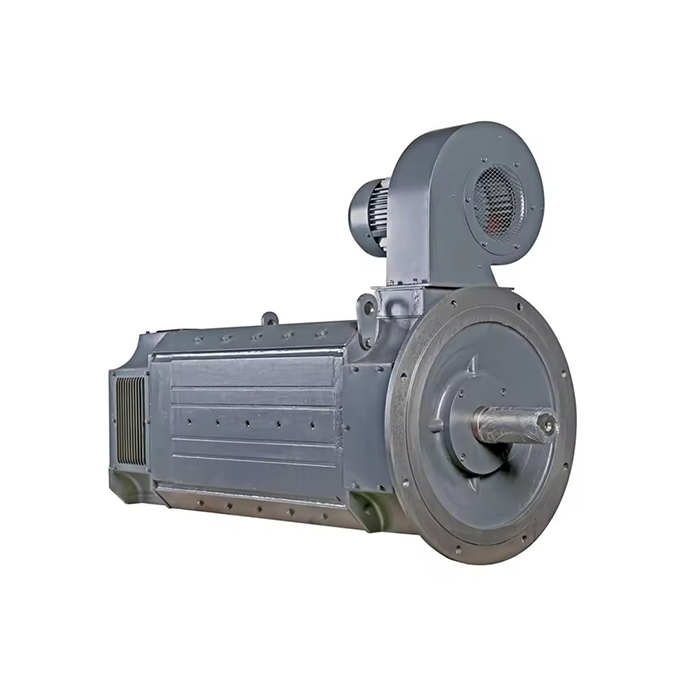

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding DC Motor Fundamentals in Automation

DC engines have revolutionized mechanical mechanization due to their extraordinary speed control capabilities. Not at all like AC engines, coordinate current engines offer straight speed-torque connections that make them perfect for exactness applications. The engine control frameworks can alter voltage levels to accomplish correct speed necessities, making them idealize for forms requiring variable speed operation.

Modern robotization frameworks depend intensely on the unsurprising behavior of DC engines. When you interface a DC engine to a programmable logic controller (PLC), the framework picks up the capacity to react immediately to changing stack conditions. This responsiveness gets to be pivotal in applications where timing and accuracy matter most.

The control supply necessities for these engines are clear compared to three-phase AC frameworks. A single DC control source can nourish numerous engines through appropriate distribution systems. This straightforwardness decreases establishment complexity and upkeep necessities in large computerization facilities.

Core Applications of 20 HP DC Motors in Industrial Automation

Conveyor System Operations

Conveyor systems represent one of the most common applications for 20 hp dc electric motors in automation. A 20-horsepower unit can handle substantial material loads while maintaining consistent belt speeds. The motor efficiency in these applications typically reaches 91%, reducing energy consumption significantly compared to older motor technologies.

Material handling systems benefit from the instant torque delivery that DC motors provide. When products enter or exit the conveyor, the motor adjusts immediately to maintain constant speed. This capability prevents product damage and ensures smooth production flow throughout manufacturing facilities.

Robotic Drive Systems

Robotics applications require exact engine control for exact situating and development. DC engines exceed expectations in these situations since they can begin, halt, and invert heading rapidly. The tall beginning torque - regularly 200% of appraised torque - empowers robots to overcome inactive grinding and start development smoothly.

Industrial robots utilize these engines for joint development, arm positioning, and end-effector control. The variable speed capabilities permit robots to move gradually amid accuracy assignments and quickly amid fabric exchange operations. This flexibility makes DC engines vital in present-day automation.

Machine Tool Applications

CNC machines and automated manufacturing equipment rely on DC motors for spindle drives and feed mechanisms. The precise speed control enables machining operations to maintain exact cutting speeds, improving product quality and tool life. Load capacity becomes critical when cutting harder materials or performing heavy-duty operations.

The thermal management systems in these motors prevent overheating during continuous operation. Advanced cooling methods ensure stable performance even under demanding machining conditions. This reliability reduces downtime and maintenance costs in production environments.

Pump and Compressor Control

Process control systems use DC motors to drive pumps and compressors with variable flow requirements. The energy consumption decreases significantly when motors operate at reduced speeds during low-demand periods. This efficiency improvement can reduce operational costs by 20-30% compared to constant-speed alternatives.

Water treatment facilities and chemical processing plants particularly benefit from this application. The motor winding designs in modern DC motors handle the frequent speed changes without degrading performance. This durability ensures long service life in critical process applications.

Packaging Equipment Integration

Automated packaging lines require synchronized motor movements to coordinate multiple stations. DC motors provide the precise timing control needed for filling, sealing, and labeling operations. The drive system can adjust speeds instantly to accommodate different product sizes or packaging requirements.

The compact design of modern DC motors allows integration into tight spaces common in packaging machinery. Multiple motors can work together through coordinated control systems to achieve complex packaging sequences with high reliability and repeatability.

Textile Manufacturing Automation

Textile production requires consistent tension control and precise speed regulation across multiple process stages. DC motors excel in these applications because they maintain constant torque output across wide speed ranges. This characteristic ensures uniform product quality in spinning, weaving, and finishing operations.

The brushless motor technology available in modern units reduces maintenance requirements significantly. Traditional brush replacement schedules can interrupt production, but newer designs eliminate this concern while maintaining the superior control characteristics of DC technology.

Steel and Metal Processing

Rolling mills and metal forming equipment use high-power DC motors for their ability to handle extreme loads and provide precise speed control. The overload capacity - typically 150% for 60 seconds - allows these motors to handle the varying loads common in metal processing applications.

The gearbox integration with DC motors enables the high torque multiplication needed for heavy metalworking operations. Combined with sophisticated control systems, these installations can process materials with exceptional precision while maintaining high production rates.

Installation and Configuration Guidelines

Proper installation begins with evaluating the existing power infrastructure. 20 hp dc electric motor installations require dedicated power supplies with appropriate voltage regulation. The installation team must consider power factor correction and harmonic filtering to ensure clean power delivery to sensitive control electronics.

Environmental factors play a crucial role in motor performance and longevity. Adequate ventilation, protection from contamination, and proper mounting all contribute to reliable operation. The protection rating of IP23 provides sufficient defense against most industrial environments while allowing necessary airflow for cooling.

Control system integration requires careful attention to signal compatibility and communication protocols. Modern automation systems use digital interfaces that must match the motor controller specifications. Proper grounding and shielding prevent electromagnetic interference that could disrupt sensitive control signals.

Maintenance and Optimization Strategies

Regular support guarantees ideal execution and amplifies engine life essentially. Preventive support plans ought to incorporate brush assessment (on the off chance that pertinent), bearing oil, and electrical association checks. Advanced demonstrative apparatuses can screen engine execution persistently and anticipate support needs some time recently disappointments occur.

Performance optimization includes altering control parameters to coordinate particular application prerequisites. Speed control calculations can be tuned to give the correct reaction characteristics required for each application. This customization maximizes proficiency while guaranteeing solid operation beneath all anticipated stack conditions.

Energy administration frameworks can screen control utilization designs and recognize optimization opportunities. By analyzing working information, offices can alter working plans and speed profiles to minimize energy costs while keeping up with generation requirements.

Safety Considerations and Best Practices

Electrical security conventions are basic when working with high-power DC systems. Appropriate lockout/tagout strategies must be taken during upkeep exercises. Workforce preparation ought to cover the particular risks related to DC electrical systems, including circular segment streak assurance and secure work practices.

Emergency halt frameworks must be legitimately planned and frequently tested to guarantee fast engine shutdown when required. The control frameworks ought to incorporate numerous layers of security to anticipate unsafe working conditions and secure both gear and personnel.

Regular security reviews offer assistance in distinguishing potential dangers some time recently they cause occurrences. These reviews ought to look at both electrical and mechanical angles of the establishment, including watches, emergency stops, and warning systems.

Conclusion

The successful implementation of a 20 HP DC electric motor in automation systems depends on understanding application requirements, proper installation, and ongoing maintenance. These motors provide exceptional speed control, high starting torque, and reliable performance across diverse industrial applications. From conveyor systems to robotic operations, DC motors continue to play a vital role in modern automation. With proper selection, installation, and maintenance, these motors deliver years of dependable service while improving operational efficiency and reducing energy costs. The investment in quality DC motor technology pays dividends through enhanced productivity and reduced downtime in critical automation applications.

Frequently Asked Questions

Q1: What voltage options are available for 20 HP DC motors?

A: Most 20-horsepower DC motors operate at standard voltages, including 240V, 400V, and 440V configurations. Custom voltage options can be manufactured to meet specific application requirements. The voltage selection depends on available power infrastructure and control system compatibility.

Q2: How does motor efficiency compare between DC and AC motors in automation applications?

A: Modern DC motors achieve efficiency ratings of 91% or higher, comparable to premium AC motors. However, DC motors provide superior speed control precision and faster response times, making them more efficient for applications requiring frequent speed changes or precise positioning.

Q3: What are the typical maintenance requirements for DC motors in continuous operation?

A: Brushless DC motors require minimal maintenance, primarily bearing lubrication and electrical connection inspection. Brushed motors need periodic brush replacement, typically every 2000-5000 operating hour,s depending on application conditions. Regular thermal monitoring helps prevent overheating issues.

Partner with XCMOTOR for Your Industrial Automation Needs

Choosing the correct 20 hp dc electric motor supplier is crucial to avoiding expensive delays and ensuring the project's success. DC motors of the highest quality, designed for rigorous industrial use, are XCMOTOR's forte. With power ratings ranging from 1.5 to 600 kW, our Z4 series motors provide outstanding performance, satisfying a wide variety of automation needs in a wide range of sectors.

Several certifications attest to our dedication to quality; they include CE compliance and ISO 9001:2015. To guarantee performance and dependability that beyond industry requirements, every motor is subjected to extensive testing. For uninterrupted business operations, take advantage of our 30-day return policy and specialized assistance, which includes weekend service.

Whatever your automation needs may be, from a single motor for a single application to a whole system of units, our technical staff is here to help you every step of the way. We tailor our solutions to meet the individual demands of each automation project, since we know that no two projects are the same.

Ready to enhance your automation systems with reliable, high-performance DC motors? Our experienced team stands ready to discuss your project requirements and recommend the ideal motor solution. Contact us at xcmotors@163.com to start your consultation today.