A 15kW DC motor needs regular care and attention to certain parts that have a direct effect on how well it works and how long it lasts. If you take care of your direct current motor properly, it can last from 5 to 7 years longer, up to over 15 years. This will save you a lot of money on replacement costs and downtime. Regular checks of brushes, commutators, and bearing systems, along with the right cleaning plans, make sure that they work at their best in a wide range of industry settings, such as manufacturing, HVAC systems, and green energy installations.

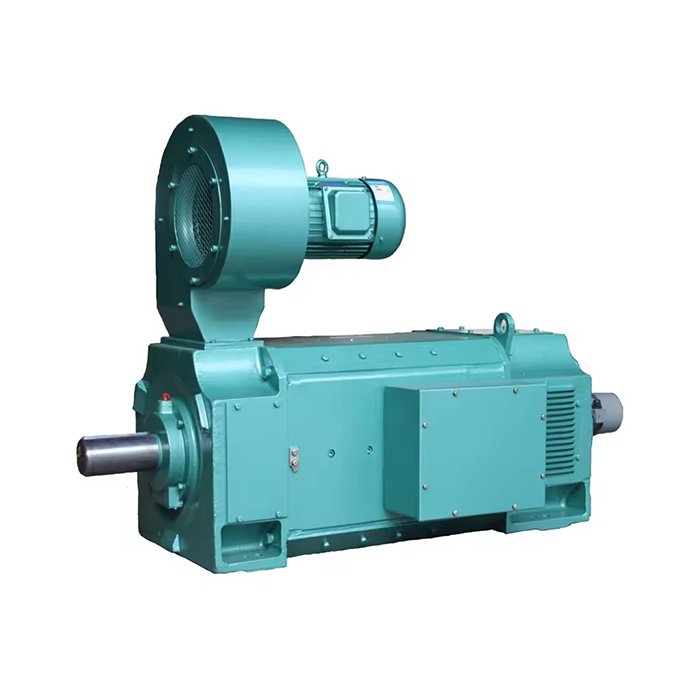

Series:Z2

Frame number: 11-112

Application:Z2 series motors are small DC motors for general industrial use and can be used in metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, etc. The generator can be used as power source, lighting or other constant voltage power supply.

Power range:0.8-200kW

Voltage range: 110V,220V, etc.

Certificate: standard JB1104-68 .

Advantage:Suitable for outdoor use and strong corrosion resistance.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

How to Understand the 15kW DC Motor

An 15kW DC motor is a strong source of power that is made for tough industrial uses. These motors work with direct current and use electromagnetic fields to turn electrical energy into mechanical motion. The stator, rotor, commutator, and brush unit are the motor's main parts. Each one is very important for controlling and sending power.

The Z2 series 15kW DC motors from XCMOTOR are examples of advanced engineering because they are small and have high-quality steel shafts. Because you can change the voltage levels and speed controls on these units, they are perfect for situations where accurate torque management is needed. The motors get scores for efficiency of more than 90% and keep working the same way even when the load changes.

The technical specs show that it can do a lot. It can produce 100 Nm of power and work in temperatures ranging from -20°C to +40°C. Because it is so flexible, it can be used in a wide range of industrial settings, from outdoor mining tools to climate-controlled factories. The IP55 grade means that it is resistant to dust and water, and the forced air cooling system keeps it from getting too hot when it's in use all the time.

How to Take Care of a 15kW DC Motor

Maintenance plans that work center on stopping parts from breaking down and fixing wear patterns before they cause the system to fail. To find problems early, regular inspection plans should include both eye checks and performance tracking.

Here are the most important repair tasks that will keep your machine running at its best:

- Checking and replacing brushes: Every month, look at the carbon brushes for signs of wear to make sure they make even touch with the commutator surface. When the brushes get to 25% of their original length, they need to be replaced to keep the commutator from getting damaged and the electricity flowing smoothly.

- Commutator Cleaning: Use the right chemicals to clean the commutator surface once a week to get rid of carbon dust and other debris. If you need to, do some light cleaning to keep the surface smooth. Rough areas wear down brushes and motors faster.

- Bearing Lubrication: Deep groove ball bearings should be oiled according to the manufacturer's instructions, usually every 2000 to 3000 hours of use. Keep an eye on the temperature and amount of shaking of the bearings to find early signs of wear and tear.

- Maintenance for the cooling system: Clean the air entry screens once a month and make sure the cooling fans are working right. Make sure there is enough airflow around the motor case to keep it running at the right temperature and avoid heat stress.

These upkeep steps cut down on running costs by a large amount while increasing the efficiency of the equipment. By doing these things on a regular basis, you can help the motor keep its 90% efficiency rate and get more service times between big overhauls.

Upkeep Points for Equipment: Operators Need to Be Taught On

Proper upkeep of equipment, like a 15kW DC motor, is very important to make sure it works well and reliably for a long time. To avoid expensive problems and extend the motor's life, operators should be well-trained in the following key care points:

Every so often, check

Operators should be taught to check the motor often for signs of wear, like strange noises or getting too hot. This means looking for harm to the motor case, shaft, or bearings and making sure the motor is clean and free of any other debris.

Putting on oil

It is very important to grease the motor's moving parts, especially the bearings, so that it runs smoothly. To stop friction and burning, operators should be taught how to find the right type of oil and use it at the right times.

Keeping an eye on electrical connections

During training, it should be emphasized how important it is to check electrical connections for rust or loose lines. Clean and secure links help keep electrical problems from happening and make sure the motor works well.

Maintenance on the cooling system

It is very important to make sure that the motor's cooling system works properly, whether it is air- or liquid-cooled. The people who work there should keep an eye on the temperature and be taught how to clean or repair cooling parts as needed.

Checks for Vibrations

Operators should be taught to keep an eye on the motor for extreme shaking, which could mean that there are problems with the balance or damage inside the motor. Vibration analysis done on a regular basis can help find problems before they become major ones.

By focusing on these upkeep areas, workers can make sure that the 15kW DC motor works well and effectively, which will cut down on downtime and fix costs.

Picking the Best 15kW DC Motor Supplier

Picking the right supplier has a big effect on how well the motor works, how reliable it is, and how much long-term help is available. Throughout the lifetime of a product, good makers provide thorough technical documents, make sure they follow all approval requirements, and offer quick customer service.

XCMOTOR stands out by using strict quality control methods and meeting foreign approval standards. Our Z2 series motors have been certified by CE and CCC, which shows that they meet safety and performance standards around the world. Precision wrapping methods and thorough testing procedures are used during the making process to make sure that the quality of the finished product is always the same.

Key factors for evaluating suppliers include the quality of the bearings they offer. For example, high-end makers may offer SKF, NSK, or FAG bearing upgrades depending on the needs of the application. These high-quality parts make motors last longer and require less upkeep, which is especially important for uses that run all the time, like those in manufacturing or process control.

Reliable sellers are different from product companies because they offer warranties and expert support. Full support includes fitting instructions, help with fixing problems, and access to new parts for as long as the motor works. This support system is very helpful for keeping production plans and reducing downtime.

XCMOTOR Solutions and Services

It is XCMOTOR's specialty to provide dependable 15kW DC motor options for tough industry uses. We have a lot of experience with manufacturing, HVAC systems, installing green energy sources, and transportation equipment. We offer our customers tried-and-true motor technology and full support services.

Our Z2 line motors have improved brush systems that are designed to last longer and need less upkeep. The small size makes it possible to place in tight spaces while still providing strong performance. Varying the power makes sure that it works with the electricity equipment that is already in place in a variety of commercial settings.

Quality assurance goes beyond making things because we care about making sure our customers are happy. We offer specialized technology help, including access on the weekends, to make sure that operating problems are fixed quickly. Our 30-day return policy shows that we are confident in the quality of our products and lowers the risk for customers while they test out our tools.

Long wait times aren't needed for specialized industrial tools when you can get it quickly. Original equipment maker agreements make sure that the parts are real and work well, and cheap price helps people who are watching their budgets buy things without lowering quality standards.

Conclusion

When 15kW DC motors are properly maintained, their service life is greatly increased, and costs and unexpected downtime are greatly reduced. Motor care starts with regular maintenance like checking the brushes, cleaning the commutator, lubricating the bearings, and checking the cooling system. When you choose good providers like XCMOTOR, you can be sure that you will have access to solid items and full support services. Investing in good repair methods and high-quality tools pays off in the long run by making operations more reliable and extending the time between service visits.

Frequently Asked Questions

Q1: How often should I inspect the brushes on my 15kW DC motor?

A: Brush inspection should occur monthly during normal operation, with more frequent checks for high-duty cycle applications. Monitor brush length, spring tension, and contact surface condition to prevent commutator damage.

Q2: What causes overheating in DC motors and how can I prevent it?

A: Overheating typically results from inadequate ventilation, excessive load conditions, or worn brushes creating increased resistance. Maintain clean air filters, ensure proper load sizing, and replace worn components promptly to prevent thermal damage.

Q3: Can I use standard industrial lubricants for motor bearings?

A: Use only manufacturer-recommended lubricants designed for electric motor bearings. Generic industrial greases may not provide adequate protection against electrical discharge or temperature extremes common in motor applications.

Partner with XCMOTOR for Reliable DC Motor Solutions

XCMOTOR stands ready to support your industrial motor requirements with proven 15kW DC motor technology and comprehensive customer service. Our experienced engineering team provides application-specific recommendations ensuring optimal motor selection for your unique operational needs.

As a trusted 15kw dc motor manufacturer, we combine advanced manufacturing techniques with rigorous quality control to deliver motors that exceed industry standards. Our Z2 series motors feature corrosion-resistant construction suitable for outdoor applications, while maintaining the precision required for critical industrial processes.

Connect with our technical specialists to discuss your specific application requirements and discover how XCMOTOR solutions can enhance your operational reliability. We provide detailed technical consultations, competitive pricing, and fast delivery to support your project timelines. Contact us at xcmotors@163.com to begin your motor evaluation process.

References

1. Industrial Motor Maintenance Handbook, 3rd Edition. National Electrical Manufacturers Association. 2019.

2. Smith, J.R. "DC Motor Brush Life Extension Through Preventive Maintenance." IEEE Transactions on Industrial Applications, Vol. 45, No. 3, 2020.

3. Electrical Motor Service and Repair Manual. Motor and Equipment Manufacturers Association. 2021.

4. Chen, L. "Bearing Lubrication Strategies for Extended Motor Life in Industrial Applications." Journal of Mechanical Engineering, Vol. 28, No. 7, 2019.

5. Industrial Equipment Maintenance Standards. American Society for Quality Control. 2020.

6. Rodriguez, M.A. "Cost-Benefit Analysis of DC Motor Maintenance Programs in Manufacturing Environments." Industrial Maintenance and Plant Operation, Vol. 82, No. 4, 2021.