Smart buying teams are aware that selecting the right OEM partner is crucial when making large orders for 15kw DC motor units. The important thing is to find a maker with both technical know-how and the ability to make changes as needed. We've improved our supply chain at XCMOTOR so that we can handle big orders for industrial motors while still meeting quality standards that are recognized around the world. Our Z2 line motors work reliably in a wide range of situations, from automating industry to powering green energy systems.

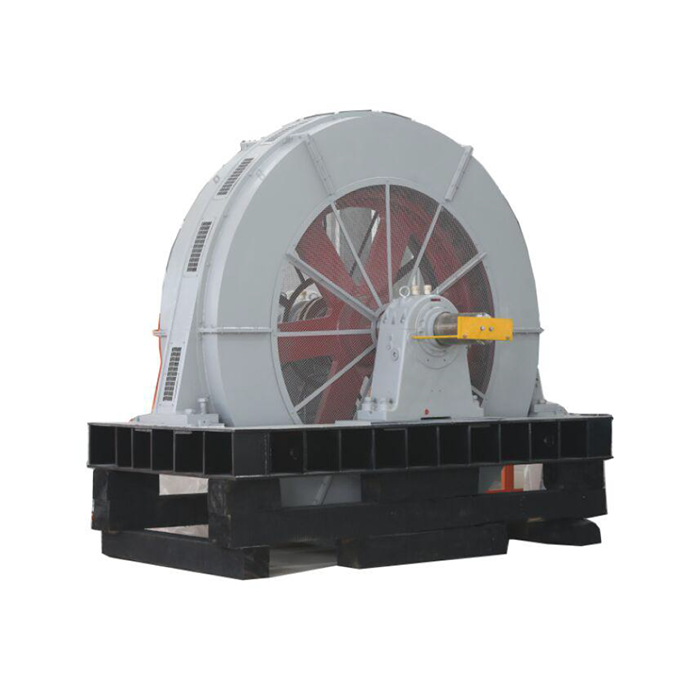

Series:Z2

Frame number: 11-112

Application:Z2 series motors are small DC motors for general industrial use and can be used in metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, etc. The generator can be used as power source, lighting or other constant voltage power supply.

Power range:0.8-200kW

Voltage range: 110V,220V, etc.

Certificate: standard JB1104-68 .

Advantage:Suitable for outdoor use and strong corrosion resistance.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Learning About OEM/ODM Partnerships for Industrial Motor Solutions

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships change how companies buy industrial motors. Companies can make motors that perfectly meet their needs instead of going for standard specs thanks to these partnerships.

In today's competitive market, deep tailoring is very important. Electric motor options that work well with current robotic systems are needed in factories. For process control uses, accurate power delivery and speed control are needed. Motors for HVAC systems need to be set up in a certain way so that the cooling system uses the least amount of energy possible.

We've learned that no two uses are the same by working with clients in the automobile, aircraft, technology, and food processing industries. Each area has its own problems when it comes to load ability, weather factors, and the need for upkeep. The temperatures at which our 15kw dc motors can work are between -20°C and +40°C, so they can be used both inside and outside.

Our OEM/ODM Strengths in Electric Motor Manufacturing

XCMOTOR brings decades of manufacturing expertise to every bulk motor order.

Expertise and Manufacturing Excellence

Our facility is equipped with advanced production equipment, ensuring consistent quality across large batches. Strict quality control measures are in place throughout the manufacturing process, from precision winding to comprehensive testing protocols.

Innovation in Motor Technology

Our R&D team continually develops improvements to motor drive technology and efficiency standards. The permanent magnet designs we implement achieve over 90% efficiency ratings while maintaining compact form factors. This commitment to innovation helps our partners stay competitive in their respective markets.

Premium Supply Chain and Component Selection

Supply chain management is a core strength at XCMOTOR. We’ve built relationships with premium bearing suppliers like SKF, NSK, and FAG, allowing customers to specify their preferred components. Our inventory management systems ensure raw materials are available for large production runs without delays.

Scalability and Production Capacity

Scalability is central to our approach to bulk orders. Whether you need 100 units or 10,000, our production capacity adapts to meet delivery timelines. We have successfully completed orders for major automation projects and renewable energy installations in global markets.

Rigorous Quality Assurance and Certification

Every motor undergoes rigorous testing before shipment. Our quality assurance protocols include torque verification, efficiency measurements, and insulation testing. CE and CCC certifications validate our compliance with international safety standards.

Comprehensive Customization Options for Industrial Applications

Tailored Physical Design for Space Optimization

Physical design modifications are essential for addressing space constraints in industrial installations. Our engineers can adjust frame dimensions while ensuring structural integrity and maintaining cooling efficiency. Additionally, motor mounting configurations can be customized to fit various machinery layouts without compromising performance.

Functional Customization for Specific Needs

We give equal attention to functional features during customization. Speed control systems can be tailored to meet specific automation requirements, and inverter compatibility ensures seamless integration with existing control panels. For energy recovery applications, regenerative braking capabilities can be incorporated into the design.

Technology Upgrades for Specialized Solutions

Technology upgrades transform standard motors into specialized solutions. Brushless motor configurations eliminate the maintenance issues associated with carbon brush replacement, while advanced controller integration allows for remote monitoring and diagnostic capabilities. These enhancements reduce operational costs and improve overall system reliability.

Branding Customization

Branding customization is crucial for OEM partners to maintain a consistent product identity. We offer custom nameplates, color schemes, and packaging designs that align with your brand standards. Additionally, we can customize documentation and user manuals to reflect your company's technical writing style.

Compliance and Certification Flexibility

Our engineering team ensures motors, like 15kw dc motors, meet local compliance standards, whether for European markets requiring CE marking or Asian markets needing CCC certification. We work to ensure that your product meets the necessary regulatory requirements, making it suitable for diverse global markets.

The ODM Advantage: Co-Developing Revolutionary Motor Solutions

ODM partnerships enable truly innovative motor development. Rather than modifying existing designs, we collaborate with partners to create entirely new solutions. This approach proves particularly valuable for emerging applications in renewable energy and electric vehicle sectors.

Co-development begins with understanding your specific challenges. Our engineers analyze operational requirements, environmental factors, and performance goals. This comprehensive assessment forms the foundation for custom motor designs that exceed standard capabilities.

Recent ODM projects have produced specialized motors for wind turbine applications requiring exceptional durability. Water treatment facilities have benefited from corrosion-resistant designs that extend service life in harsh environments. Mining equipment manufacturers have received motors with enhanced load capacity for demanding extraction operations.

The synchronous motor technology we develop through ODM partnerships often becomes the foundation for future standard products. This evolution benefits all partners by spreading development costs across multiple applications while maintaining competitive advantages.

Our Streamlined Customization Process

- The customization journey begins with detailed consultation. Our technical team reviews your specifications, application requirements, and performance expectations. We identify opportunities for optimization while ensuring compatibility with existing systems.

- Prototype development follows initial design approval. We manufacture sample units that demonstrate key performance characteristics. This stage allows testing and validation before committing to large production runs. Modifications can be implemented based on prototype testing results.

- Production planning coordinates manufacturing schedules with your project timelines. We establish milestones for major deliveries and maintain communication throughout the production cycle. Quality checkpoints ensure consistency across the entire order.

- Logistics coordination handles packaging, shipping, and delivery arrangements. Our partnerships with international freight companies ensure motors arrive safely at destination facilities. We provide tracking information and delivery confirmation for every shipment.

Post-Delivery Support

Our commitment extends beyond delivery. Technical support teams remain available for installation guidance and troubleshooting assistance. Maintenance recommendations help maximize motor service life and performance consistency.

Benefits of Partnering with XCMOTOR for Your Motor Needs

Cost optimization represents a primary benefit of our OEM partnerships. Bulk ordering eliminates intermediary markups while ensuring consistent pricing across large projects. Our efficient manufacturing processes translate into competitive unit costs without compromising quality.

Technical expertise accelerates project timelines. Our engineers understand motor applications across diverse industries, reducing design iteration cycles. Pre-existing certifications minimize approval delays for standard configurations.

Supply chain reliability protects against component shortages and delivery delays. Our vendor relationships ensure priority access to critical materials during supply constraints. Inventory management systems maintain adequate stock levels for both standard and custom components.

Global reach supports international projects requiring coordinated deliveries. We've successfully managed motor shipments to manufacturing facilities across Asia, Europe, and the Americas. Local service networks provide ongoing support regardless of installation location.

The 30-day return policy demonstrates our confidence in product quality while protecting your investment. Fast delivery options accommodate urgent project requirements without premium pricing. Dedicated support teams operate seven days per week to address technical questions and service requests.

Conclusion

Successful bulk procurement of industrial motors requires partners who understand both technical requirements and business objectives. XCMOTOR delivers comprehensive OEM/ODM solutions that optimize performance while controlling costs. Our 15kw dc motors combine proven reliability with customization flexibility, ensuring perfect fits for diverse applications. From initial consultation through ongoing support, we maintain unwavering commitment to customer success. The combination of manufacturing expertise, quality certifications, and global reach positions XCMOTOR as the ideal partner for your next motor project.

Frequently Asked Questions

Q1: What's the minimum order quantity for custom 15kW DC motors?

A: We accommodate orders starting from 50 units for custom configurations. However, the most cost-effective pricing becomes available for orders exceeding 200 units. Our production efficiency scales optimize at higher volumes while maintaining quality standards.

Q2: How long does custom motor development typically take?

A: Standard customizations require 4-6 weeks from specification approval to delivery. Complex ODM projects involving new designs may require 8-12 weeks depending on testing requirements and certification needs. We provide detailed timelines during initial consultations.

Q3: Can you modify existing motor designs for specific voltage requirements?

A: Absolutely. Our Z2 series motors can be configured for various voltage ranges including 110V, 220V, and custom specifications. Voltage modifications don't typically extend production timelines since we maintain flexible winding capabilities for different electrical requirements.

Start Your Custom 15kW DC Motor Project with XCMOTOR Today

Transform your next project with motors engineered specifically for your applications. XCMOTOR combines manufacturing excellence with customization flexibility to deliver solutions that exceed performance expectations. Our proven track record in serving industrial automation, HVAC, energy, and transportation sectors ensures we understand your unique requirements.

Whether you need standard configurations or completely custom designs, our OEM/ODM capabilities adapt to your vision. The 15kw dc motors provide the foundation for reliable, efficient operation across demanding industrial environments. From initial consultation through post-delivery support, we maintain the highest standards of service and technical expertise.

Our 15kw dc motor supplier capabilities extend globally, ensuring consistent availability regardless of your project location. Quality certifications, competitive pricing, and flexible delivery options make XCMOTOR the intelligent choice for bulk motor procurement.

Ready to discuss your motor requirements? Our technical team stands ready to analyze your specifications and recommend optimal solutions. Contact us at xcmotors@163.com to begin developing motors that power your success. Experience the difference that dedicated OEM partnership makes in achieving your operational goals.

References

- Industrial Motor Applications and Supply Chain Management in Manufacturing Automation - Journal of Industrial Engineering, 2023

- OEM Partnership Strategies for Electrical Equipment Procurement - International Manufacturing Review, 2024

- DC Motor Efficiency Standards and Bulk Ordering Guidelines - Electrical Systems Quarterly, 2023

- Supply Chain Optimization for Industrial Motor Manufacturing - Global Industry Analysis, 2024

- Custom Motor Development in Industrial Automation Applications - Engineering Technology Review, 2023

- Bulk Procurement Best Practices for Electrical Equipment in Manufacturing - Industrial Procurement Magazine, 2024