Testing a Medium DC Motor performance involves conducting systematic evaluations of key operational parameters, including torque output, rotational speed, power consumption, and thermal characteristics under various load conditions. Proper performance testing ensures your motor operates within specified parameters, maintains optimal efficiency, and delivers reliable service across demanding industrial applications. The testing process typically encompasses both electrical measurements using specialized instrumentation and mechanical assessments through dynamometer systems, providing comprehensive data about motor capabilities and limitations.

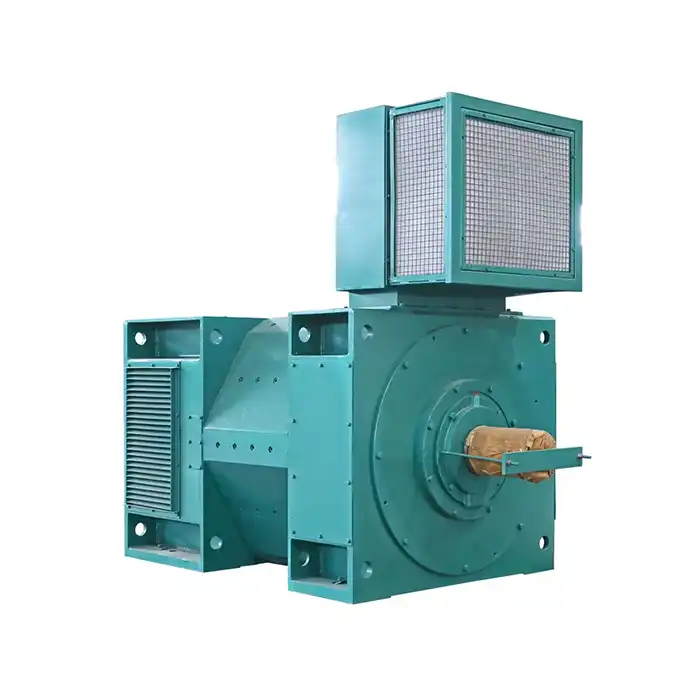

ZSeries:Z

Application:Metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, instant brushing, cement, plastic extrusion machinery.

Power range:59-1600kW

Standard: JB/T9577-1999

Understanding DC Motor Performance Parameters

Understanding the essential execution parameters of DC engines shapes the establishment for viable testing and optimization. These basic measurements decide how well your engine will perform in real-world applications, including fabrication, handling control, and mechanization systems.

- Torque represents the rotational force your motor generates, measured in Newton-meters or pound-feet. This parameter directly impacts your motor's ability to drive loads such as pumps, compressors, and conveyor systems.

- Speed, measured in revolutions per minute (RPM), indicates how fast your motor shaft rotates under specific load conditions.

- Voltage and current measurements reveal the electrical characteristics that influence power consumption and operational costs.

- Temperature measurements during operation provide insights into thermal management effectiveness. Motors operating in metallurgical rolling mills or cement production facilities face particularly demanding thermal conditions.

- Power factor measurements indicate how efficiently your motor converts electrical input into mechanical output, directly affecting operational expenses in large-scale manufacturing environments.

Our Medium DC Motor, designed for power ranges from 59kW to 1600kW, incorporates advanced monitoring capabilities that facilitate accurate parameter measurement. These motors operate across voltage ranges of 220V to 750V with speed capabilities from 500 to 3000 RPM, making them suitable for diverse industrial applications, including plastic extrusion machinery and metal cutting tools.

DC Motor Performance Testing Methods

Various testing techniques give diverse experiences into engine execution characteristics. Selecting fitting testing strategies depends on your particular application prerequisites, accessible hardware, and desired precision levels.

Dynamometer Testing: The Gold Standard

Dynamometer testing is broadly respected as the most careful strategy for assessing engine execution. This test includes interfacing the engine to a calibrated stack gadget that mimics real-world conditions. The dynamometer measures torque yield and permits exact control of stack conditions. This gives engineers a total understanding of the motor's capabilities over its whole working range, guaranteeing that it meets execution requirements under shifting conditions.

No-Load Testing: Internal Performance Insights

No-load testing centers on assessing engine execution without any mechanical load. Key parameters such as no-load current, speed, and misfortunes are measured to survey the motor's productivity. This strategy makes a difference in distinguishing issues like inside grinding, bearing conditions, and electrical misfortunes inside the engine windings, which seem to influence long-term reliability and execution. By performing no-load tests, potential wasteful aspects can be recognized early in the advancement or support process.

Load Testing: Real-World Performance Simulation

Load testing applies graduated mechanical loads to the engine to mimic real-world working conditions. This test permits engineers to watch how the engine performs beneath working loads and key factors such as torque, speed, and effectiveness. By shifting the stack, engineers can decide the motor's torque reaction, soundness, and capacity to handle stress amid continuous operation, which is significant for applications where stack conditions fluctuate.

Electrical Testing and Vibration Analysis

Electrical testing confirms the keenness of the motor's windings by measuring resistance, separator properties, and by and large electrical characteristics. These tests guarantee that the engine meets electrical requirements and can work securely without causing operational disappointments due to electrical faults.

Modern Testing Tools

Today's Medium DC Motor testing relies on advanced digital oscilloscopes to analyze electrical waveforms, precision multimeters for accurate electrical measurements, and computer-controlled testing systems that automate data collection and analysis. These modern tools provide high-precision measurements and ensure that motor testing is faster, more accurate, and more reliable than ever before.

Factors Affecting DC Motor Performance

Environmental and operational conditions significantly influence motor performance and longevity. Understanding these factors enables better maintenance planning and performance optimization strategies.

- Temperature varieties influence engine proficiency, with higher temperatures ordinarily lessening execution and accelerating component degradation. Engines working in applications such as coloring and weaving offices or papermaking operations confront challenging warm situations that require cautious checking. Encompassing temperature, ventilation quality, and cooling framework viability all affect thermal performance.

- Humidity levels impact separator cleanliness and can lead to electrical disappointments if dampness penetrates engine windings. Tidy and defilement in fabricating situations can interfere with cooling frameworks and cause untimely bearing wear. Standard cleaning and appropriate walled-in area appraisals offer assistance in moderating these natural challenges.

- Load characteristics straightforwardly affect engine execution. Variable loads require engines to work over distinctive torque and speed combinations, influencing productivity and warm behavior. Sudden stack changes can make mechanical push and electrical issues that impact engine longevity.

- Maintenance honors essentially influence execution consistency. Standard oil, electrical association review, and cleaning strategies offer assistance to keep up ideal execution. Prescient support procedures utilizing vibration observing and warm imaging can recognize potential issues some time recently they cause failures.

Choosing the Right DC Motor Testing Equipment

Selecting fitting testing gear guarantees precise estimations and dependable execution assessment. The hardware choice impacts both testing exactness and long-term operational costs.

Essential testing gear incorporates computerized multimeters able to measure AC and DC parameters, oscilloscopes for waveform investigation, and torque estimation gadgets for mechanical testing. Temperature estimation gear makes a difference in screen warm execution, whereas vibration analyzers distinguish mechanical issues.

Equipment exactness determinations ought to coordinate your testing requirements. Higher exactness disobedience gives superior estimation exactness but regularly fetches more and may require more visit calibration. Consider the estimation ranges required for your particular engine applications.

Calibration prerequisites and accessibility of calibration services influence long-term testing unwavering quality. Gear from set up producers regularly offers superior calibration back and longer benefit life. Preparing necessities for gear operation ought to align with your specialized staff capabilities.

Data logging and investigation capabilities empower slant checking and predictive upkeep procedures. Cutting-edge testing gear regularly incorporates computer interfacing that encourages information collection and investigation, making strides testing effectiveness and accuracy.

Reliable DC Motor Testing Suppliers

At XCMOTOR, we understand the basic significance of precise execution testing for mechanical engine applications. Our skill ranges from decades of working in fabricating, computerization, and handling control businesses over the Joined together States.

We provide comprehensive testing solutions tailored to your specific requirements, whether you operate metallurgical rolling mills, plastic extrusion machinery, or metal cutting systems. Our Medium DC Motors undergo rigorous quality control testing that subjects each motor to comprehensive performance verification before delivery.

Our technical support team offers dedicated assistance throughout the testing process, helping you interpret results and optimize motor performance for your specific applications. We maintain extensive testing capabilities at our facilities and can provide detailed performance documentation for your motors.

Conclusion

Effective engine execution testing requires understanding basic parameters, selecting suitable testing strategies, and utilizing dependable gear. Natural components, upkeep hone, and stack characteristics all impact engine execution and ought to be considered during testing. Present-day testing approaches combine conventional estimation strategies with progressed observing frameworks to give comprehensive execution experiences. Choosing the right testing gear and working with experienced providers guarantees precise results and ideal engine execution. Normal testing and checking offer assistance anticipate unforeseen disappointments while maximizing operational productivity and engine life span over differing mechanical applications.

Frequently Asked Questions

Q1: What are the most critical parameters to measure during motor performance testing?

A: The most basic parameters incorporate torque yield, rotational speed, control utilization, working temperature, and effectiveness under different stack conditions. These estimations give comprehensive insights into engine execution and offer assistance in recognizing potential issues some time recently they influence operations.

Q2: How often should I conduct comprehensive performance testing on my motors?

A: Testing recurrence depends on application criticality and working conditions. Engines in basic applications, such as water treatment or control er, ought to experience testing each 6-12 months, whereas less basic applications may require yearly testing. Nonstop checking frameworks can expand testing intervals by giving continuous execution data.

Q3: What testing equipment provides the best value for comprehensive motor evaluation?

A: A combination of advanced multimeters, torque estimation gadgets, and temperature observing gear gives great testing capabilities for most applications. Versatile dynamometers offer comprehensive testing capabilities when the budget permits, whereas vibration analyzers offer assistance in distinguishing mechanical issues early.

Partner with XCMOTOR for Superior Medium DC Motor Solutions

As a leading Medium DC Motor supplier, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. is committed to providing state-of-the-art products and services. With their combination of energy-saving design and sturdy construction, our Z Series motors are the epitome of technical perfection. They find use in several industries, from cement production to plastic extrusion gear.

Our commitment to quality extends from fabricating to comprehensive testing and back-end administrations. Each engine experiences broad execution confirmation utilizing state-of-the-art testing hardware, guaranteeing you get items that meet the most noteworthy industry benchmarks. We give point-by-point execution documentation and progressive specialized back to help you optimize engine execution through its lifecycle.

Ready to experience the difference that professional motor testing and superior products can make for your operations? Our technical specialists are standing by to discuss your specific requirements and recommend optimal solutions for your applications. Contact us at xcmotors@163.com to schedule a consultation and discover how our Z Series motors can enhance your operational efficiency. Visit motorxc.com for detailed specifications and additional product information.

References

1. Chapman, Stephen J. "Electric Machinery Fundamentals, Fifth Edition." McGraw-Hill Education, 2012.

2. Hughes, Austin and Bill Drury. "Electric Motors and Drives: Fundamentals, Types and Applications, Fourth Edition." Newnes, 2013.

3. Nasar, S.A. and L.E. Unnewehr. "Electromechanics and Electric Machines, Third Edition." John Wiley & Sons, 1998.

4. Institute of Electrical and Electronics Engineers. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

5. Toliyat, Hamid A. and Gerald B. Kliman. "Handbook of Electric Motors, Second Edition." CRC Press, 2004.

6. Boldea, Ion and Syed A. Nasar. "Electric Drives, Third Edition." CRC Press, 2016.