It is possible to differentiate between optimal performance and costly operational inefficiencies by precisely measuring motor inductance. Inductance monitoring is very important for slip ring rotor motors due to the complex network of electromagnetic interactions that regulates their operation. Startup properties, torque generation, and general efficiency are all affected by the inductance levels in various industrial contexts.

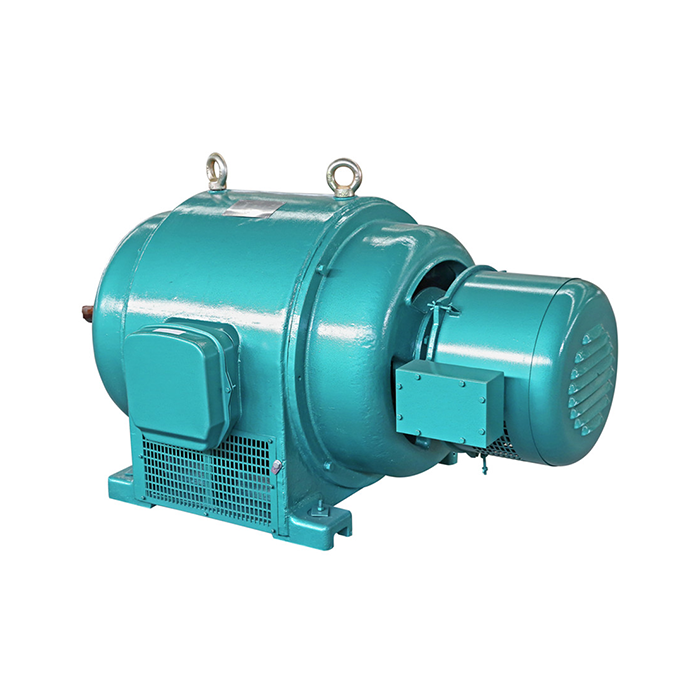

Series:YRQ

Voltage range:380V±5%

Power range:45-800kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

In a motor, inductance is a measure of the magnetic property that keeps the current passing through the windings from fluctuating. The ability of motors to respond to electrical inputs and work consistently under different loads is affected by this crucial attribute. Engineers proficient in inductance measurement are able to optimize motor selection, diagnose performance issues, and guarantee reliable operation in demanding industrial environments.

How to Measure Inductance of a Motor?

Engine inductance estimation requires particular procedures and gear to accomplish precise results. The estimation prepare includes applying controlled electrical signals to engine windings and analyzing the resulting electromagnetic reaction. Understanding legitimate estimation strategies guarantees solid information collection and important investigation of engine characteristics.

Tools and Techniques

Selecting fitting estimation instruments altogether impacts the precision and unwavering quality of inductance estimations. Distinctive rebellious offer shifting levels of accuracy, estimation extent, and operational comfort for mechanical applications.

Multimeter vs LCR Meter

Standard multimeters provide basic inductance measurement capabilities suitable for preliminary testing and field diagnostics. These instruments typically offer measurement ranges from microhenries to several henries with moderate accuracy levels. However, their measurement frequency limitations and basic circuitry may not capture the complex inductance characteristics of slip ring rotor motors under realistic operating conditions.

LCR meters provide predominant exactness and comprehensive estimation capabilities essential for detailed engine examination. These specialized degrees inductance, capacitance, and resistance at the same time over different frequencies, giving total characterization of the engine's electrical properties. Professional-grade LCR meters offer estimation exactness within 0.1% and frequency ranges from 20 Hz to 1 MHz, empowering exact examination of engine behavior beneath different working conditions.

Preparation and Safety

Proper arrangement guarantees exact estimations and administrator security during inductance testing methods. Engine windings must be totally de-energized and separated from control sources some time recently interfacing with estimation gear. Visual review of winding terminals, separator condition, and association judgment anticipates estimation errors and gear damage.

Safety conventions incorporate confirming zero energy states utilizing suitable lockout/tagout strategies and affirming appropriate installation of estimation gear. Temperature contemplations influence inductance values, so estimations ought to be taken at steady surrounding conditions or compensated for temperature variations. Documentation of estimation conditions, counting temperature, mugginess, and engine position, empowers significant comparison of outcomes over time.

Importance of Inductance in Motor Design

Inductance Impact on Performance

Motor inductance on a very basic level decides electromagnetic behavior and operational characteristics over distinctive engine types. The relationship between inductance and execution changes altogether between AC and DC engine arrangements, requiring particular thought during planning and application selection.

AC Motors vs DC Motors

AC motor inductance affects starting current, torque production, and power factor characteristics. Higher inductance values typically result in lower starting currents but may reduce starting torque capabilities. Slip ring rotor motors benefit from adjustable rotor resistance, allowing optimization of inductance effects for specific applications. The ability to modify rotor circuit characteristics enables fine-tuning of motor performance across varying load conditions.

DC engine inductance fundamentally impacts commutation quality and current swell characteristics. Lower inductance values move forward energetic reaction but may increase current swell and electromagnetic obstructions. An appropriate inductance plan equalizations reaction speed with smooth operation and satisfactory current characteristics for delicate applications.

Design Considerations

An effective engine plan requires cautious thought of inductance connections with other electrical parameters. The interaction between inductance, resistance, and capacitance generally determines engine execution and efficiency characteristics.

Balancing Inductance and Resistance

Optimal engine execution comes about from adjusted inductance and resistance values that accomplish the desired operational characteristics. Tall inductance combined with moo resistance regularly gives a smooth current stream but may constrain energetic reaction. Then again, moo inductance with higher resistance empowers quick current changes but may increase misfortunes and diminish efficiency.

Motor creators alter winding arrangements, center materials, and geometric parameters to accomplish target inductance values. The XCMOTOR YRQ arrangement utilizes optimized winding plans that adjust inductance characteristics with strong development suitable for demanding mechanical applications. These engines accomplish fabulous beginning torque (up to 280% of appraised torque) while keeping up proficient operation over their 45-800kW control range.

Comparing Inductance Measurement Methods

Advantages of Digital Inductance Meters

Digital inductance meters give predominant estimation accuracy and operational comfort compared to analog inductance meters. Advanced meters join progressed estimation calculations that compensate for temperature impacts, lead resistance, and other variables that impact estimation accuracy.

Accuracy and Ease of Use

Professional computerized inductance meters accomplish estimation exactnesses within 0.05% under controlled conditions, empowering exact characterization of engine electrical properties. Programmed extending, temperature remuneration, and information logging capabilities streamline estimation methods and decrease administrator mistakes. Numerous disobedient incorporate computer network alternatives that encourage robotized testing and data analysis for quality control applications.

User-friendly interfacing with clear shows and natural controls minimizes preparation necessities and decreases estimation time. Progressed highlights such as measurable investigation, restraint testing, and report era upgrade efficiency in manufacturing and support environments.

Choosing the Right Measurement Method

Selecting fitting estimation strategies depends on precision necessities, operational limitations, and financial considerations. Distinctive applications require shifting levels of exactness and estimation capability.

Cost vs Accuracy

Basic multimeters with inductance estimation capability fetch essentially less than proficient LCR meters but give restricted precision and usefulness. For schedule upkeep and field diagnostics, multimeter estimations may give satisfactory data for decision-making. Be that as it may, exactness engine investigation, quality control, and investigate applications require the prevalent precision and comprehensive estimation capabilities of committed LCR meters.

Investment in quality measurement equipment pays dividends through improved slip ring rotor motor selection, reduced maintenance costs, and enhanced reliability. The ability to detect subtle changes in inductance values enables predictive maintenance strategies that prevent costly unplanned outages in critical industrial processes.

Purchasing Inductance Measurement Tools

Finding Reliable Suppliers

Identifying reputable suppliers ensures access to quality measurement instruments and ongoing technical support. Established manufacturers provide comprehensive product documentation, calibration services, and application assistance that maximize measurement system effectiveness.

Fluke, Keysight, Tektronix

Leading estimation instrument producers offer comprehensive item lines traversing fundamental handheld meters to advanced laboratory-grade frameworks. Fluke gives rough, versatile disobedient products designed for field utilize in unforgiving mechanical situations. Keysight conveys accuracy, seat rebellious with progressed estimation capabilities suitable for research and development applications. Tektronix offers coordinate estimation arrangements that combine numerous estimation capacities in integrated platforms.

These producers keep up broad specialized support organizations and calibration services that guarantee estimation accuracy over extended periods. Item guarantees and repair services give extra value and minimize up to proprietorship costs.

Online Purchasing Tips

Efficient online purchasing requires careful evaluation of product specifications, supplier credentials, and total cost considerations,including shipping, calibration, and support services.

Affordable Options and Kits

Many providers offer estimation packs that incorporate rebellious, extras, and documentation at alluring bundle costs. These units regularly give way better esteem than person component buys and guarantee compatibility between framework components. Instructive rebates and volume estimating may diminish costs for larger organizations or different unit purchases.

Refurbished and utilized rebellious from legitimate merchants offer cost-effective choices to modern hardware buys. Be that as it may, calibration confirmation and guarantee scope ought to be affirmed some time recently buy to guarantee solid estimation capability.

Company Introduction and Product Information

Shaanxi Qihe Xicheng Electromechanical Hardware Co., Ltd. (XCMOTOR) specializes in giving comprehensive control gear arrangements for mechanical applications. Our commitment to tall vitality productivity, moo utilization, and steady control conveyance has established XCMOTOR as a trusted accomplice for businesses requiring dependable engine solutions.

Our fabricating handle utilizes state-of-the-art methods, including exact winding and vacuum pressure impregnation (VPI) to guarantee prevalent unwavering quality and amplified benefit life. Each engine experiences thorough testing to meet rigid quality benchmarks, conveying steady execution in demanding mechanical situations. The 380V±5% voltage extend, 45-800kW control run, and IP23 assurance level give flexibility over various applications while keeping up strong development standards.

Conclusion

Measuring engine inductance precisely empowers ideal execution and solid operation over mechanical applications. The determination of suitable estimation instruments, legitimate methods, and normal observing plans guarantees engines work at peak effectiveness, whereas recognizing potential issues, sometimes expensive disappointments happen. Understanding inductance characteristics engages engineers to make educated choices approximately engine determination, application optimization, and upkeep procedures. XCMOTOR's YRQ arrangement engines combine prevalent plan with comprehensive support services, conveying the unwavering quality and execution required by advanced mechanical applications.

Frequently Asked Questions

Q1: What is motor inductance and why is it important?

A: Engine inductance speaks to the attractive property of engine windings that restricts changes in electrical current. This principal characteristic decides the beginning current, torque generation, and, in general, engine behavior under changing stack conditions. Understanding inductance makes a difference in optimizing engine choice, foresee execution, and maintain effective operation over mechanical applications.

Q2: Can I measure inductance with a regular multimeter?

A: Whereas fundamental multimeters can degree inductance, they regularly give restricted precision and frequency extend compared to committed LCR meters. For preparatory testing and field diagnostics, multimeter estimations may suffice. Be that as it may, exactness engine investigation requires specialized disobedient that offers prevalent precision and comprehensive estimation capabilities.

Q3: How often should I measure motor inductance?

A: Inductance estimation recurrence depends on application criticality and working conditions. Basic applications may require quarterly estimations, whereas standard mechanical engines regularly require yearly testing. Trending inductance values over time make a difference in recognizing progressive winding debasement and empower predictive upkeep strategies.

Partner with XCMOTOR for Superior Motor Solutions

XCMOTOR stands ready to support your industrial motor requirements with comprehensive solutions that combine advanced engineering, quality manufacturing, and dedicated customer service. As a leading slip ring rotor motor manufacturer, we understand the critical role that precise motor characteristics play in industrial success.

Our YRQ arrangement engines convey uncommon execution with tall beginning torque capabilities, flexible speed characteristics, and amazing over-burden capacity. The comprehensive control extends from 45kW to 800kW, addressing differing mechanical necessities while keeping up steady quality benchmarks. Premium bearing choices from SKF, NSK, and FAG can be customized according to particular application needs.

Experience the XCMOTOR advantage through our commitment to original parts from trusted brands, fast delivery with free shipping, a 30-day return policy, and dedicated support, including weekend availability. Our experienced technical team provides installation, commissioning, and training services worldwide, ensuring successful motor integration into your operations. Contact us at xcmotors@163.com to discuss your specific motor requirements and discover how our solutions can enhance your industrial operations. Visit motorxc.com for complete product specifications and technical information.

References

1. Chapman, Stephen J. "Electric Machinery Fundamentals." McGraw-Hill Education, 2021. Chapter 4: Motor Inductance and Performance Characteristics.

2. IEEE Standard 115-2019. "IEEE Guide for Test Procedures for Synchronous Machines Including Acceptance and Performance Testing and Parameter Determination for Dynamic Analysis."

3. Toliyat, Hamid A., and Gerald B. Kliman. "Handbook of Electric Motors." CRC Press, 2018. Section 12: Inductance Measurement Techniques in AC Motors.

4. National Institute of Standards and Technology. "Guidelines for Electrical Measurement Accuracy in Industrial Motor Testing." NIST Technical Publication 1297, 2020.

5. Boldea, Ion, and Syed A. Nasar. "The Induction Machines Design Handbook." Taylor & Francis, 2019. Chapter 8: Electromagnetic Parameters and Their Measurement.

6. International Electrotechnical Commission. "IEC 60034-2-1:2014 Rotating Electrical Machines - Part 2-1: Standard Methods for Determining Losses and Efficiency from Tests."