Slip ring rotor motors greatly improve the performance of crushers by providing up to 280% of rated torque at startup while using very little power. These advanced motor systems let crushers handle different types of material loads quickly and easily by giving them accurate speed and torque control. The adjustable resistance function lets operators use less power during starting sequences, which puts less stress on the mechanical parts that crush. When used with current control systems, slip ring rotor motors make industrial applications more reliable, last longer, and better manage energy use.

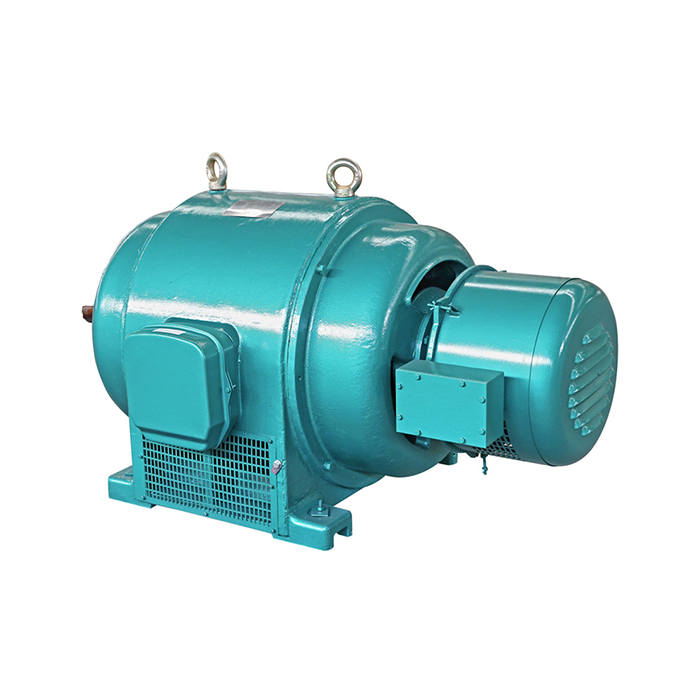

Series:YRQ

Voltage range:380V±5%

Power range:45-710kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What are Slip Ring Rotor Motors?

If you know the basics of slip ring rotor motors, you can see why these electrical devices work so well in tough industrial settings. A slip ring rotor motor features a stator with three-phase windings and a rotor with conductors that link to slip rings via brushes. This special setup lets you manage the external resistance, which makes these motors great for uses that need strong beginning torque and controlled acceleration.

The basic idea behind how it works is electromagnetic induction between the stator and rotor windings. When three-phase electricity flows through the stator, it generates a spinning magnetic field that makes currents flow through the rotor conductors. The slip rings and brushes let you add external resistance to the rotor circuit, which changes the torque and speed of the motor. This basic working principle sets slip ring rotor motors apart from squirrel cage motors, giving them better control, which is important for use in crushers.

This technology is good for industrial settings since motors that can handle abrupt changes in load and start-stop cycles are needed for crushing activities. With external rotor resistance control, the crusher can accelerate smoothly even when it is under tremendous loads. This protects the mechanical parts of the crusher from stress and keeps the power efficiency at its best throughout the operating cycle.

Benefits of Using Slip Ring Rotor Motors in Industry

Slip ring rotor motors are well suited for tough crusher applications because to their efficiency and performance qualities. These motors start up better than regular ones, giving engineers exact control over how fast they speed up and how much torque they provide.

These motor systems stand out because of these key performance benefits:

- High Starting Torque Output: With up to 280% of the specified torque, it can handle strong starting loads without damaging the motor or putting too much stress on connected equipment.

- Controlled Starting Current: Keeping the starting current between 350 and 450 percent of the rated current lowers stress on the electrical system and makes sure the motor works well during startup sequences.

- Variable Speed Capability: With external resistance control, you can change the speed from 500 to 1500 rpm very precisely, which lets you get the best results for varied materials and crushing needs.

- Improved Overload Capacity: Strong construction and thermal management systems make it possible to handle overloads very well, so the system can keep running even when demand is at its highest.

These performance benefits immediately solve frequent problems that come up while using a crusher, such as bridging materials, uneven feed conditions, and different hardness levels. A comparison between slip ring rotor motors and squirrel cage motors shows that the former have many advantages when it comes to running, especially in situations where you need to start under load often and adjust the speed very precisely for the best crushing efficiency.

Building and designing slip ring rotor motors

Slip ring rotor motors are built with a lot of different parts that work together to make them better at crushing jobs. The rotor assembly has wound conductors that link to slip rings. These slip rings connect to carbon or graphite brushes to provide access to the external circuit. This design lets you add variable resistance, which gives you exact control over the motor's properties.

New design ideas have made these motor systems far more durable and efficient. Newer materials and manufacturing methods make brushes last longer and need less upkeep. The slip ring assembly is made of high-quality conductive materials like copper or silver alloys. This makes sure that the electrical contact is reliable and that there is no resistance loss while it is working.

The stator is built using precise winding methods and vacuum pressure impregnation (VPI) technologies to improve insulation and heat transfer. This method of making things helps them last longer and work better in tough industrial settings. The strong frame design with an IP23 protection rating keeps the environment safe while yet allowing the IC01 cooling technology to work at its best.

How to fix and keep slip ring rotor motors in good shape

Slip ring rotor motors in crusher applications function at their best and last as long as they are maintained properly. Regular inspections concentrate on important parts including the condition of the brushes, the quality of the slip ring surface, and the performance of the bearings. SKF, NSK, and FAG all provide high-quality bearings that may be customized to meet particular operating needs.

Routine maintenance includes a number of important tasks that keep things running well and avoid unexpected downtime:

- Brush Inspection and Replacement: Checking the wear patterns on the brushes and the buildup of carbon dust on a regular basis keeps the electrical contact good and makes sure the motor works well all the time.

- Cleaning and checking slip ring surfaces on a regular basis keeps them conductive and prevents brushes from wearing out too quickly.

- Bearing lubrication and monitoring: Following the right maintenance schedules and keeping an eye on vibrations may make bearings last longer and save them from failing completely.

- Testing insulation: Regularly measuring the resistance of insulation may find problems with the winding before they cause it to fail.

To solve frequent problems, you need to systematically figure out what electrical and mechanical symptoms mean. Knowing how motor performance indicators and possible causes are related makes it possible to quickly find and fix operational issues, which reduces production delays in crusher applications.

How to Pick the Best Slip Ring Rotor Motor for Your Needs

Choosing the right motor specs involves careful thought about the needs of the application and how it will be used. The YRQ(JR) family of medium-sized motors can handle power levels from 45kW to 800kW and voltages from 380V±5% to 660V. This gives you a lot of possibilities for different types of crushers and electrical systems.

These motors work best in cement mills, ball mills, crushers, conveyors, and mining equipment. The strong driving capabilities let you run huge machinery like ships, cranes, and wind turbines, as well as smaller industrial equipment like pumps, compressors, and cutting machine tools.

When looking at different types of motors, slip ring rotor motors have clear benefits over other types in situations where controlled starting and variable speed operation are needed. The ability to change the resistance of the rotor lets you optimize it for different types of crushing materials and working situations. This gives you more flexibility than fixed-parameter motor designs.

Adding Slip Ring Rotor Motors to Crushers

Integrating slip ring rotor motors into crushers improves their performance by giving operators more control over the crushing process and making them use less energy. The ability to change the speed and torque lets you optimize for varied material qualities, which increases throughput while using less energy and causing less wear and tear on the machine.

Case studies from mining and aggregate processing plants show that the performance of crushers has improved a lot. Operations say that switching from traditional motor systems to slide ring rotor topologies lowers maintenance costs, speeds up material processing, and makes equipment more reliable. Controlling the acceleration profiles minimizes mechanical stress at starting, which makes the parts of the crusher last longer and lowers replacement costs.

During the integration phase, it is important to think about the needs of the electrical infrastructure and how well the control system works with it. Variable frequency drives (VFDs) are typically used in modern installations to provide operators more control over the crushing process. This lets them make exact changes to the crushing settings depending on the material's properties and the current operating circumstances.

Information about the company and its products

At XCMOTOR, we make high-quality slip ring rotor motors that are perfect for tough industrial jobs like running crushers. Our all-in-one motor solutions use cutting-edge engineering and dependable manufacturing methods to provide outstanding performance and extended life in tough working conditions.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. is all about providing power equipment solutions that concentrate on high energy efficiency, low energy usage, and dependable power delivery. We are dedicated to more than just making products; we also provide full technical assistance, which includes pre-sales consulting, installation help, and after-sales service.

We sell authentic parts from well-known manufacturers, which guarantees that they will work well and be reliable. We provide free shipping and rapid delivery, as well as a 30-day refund policy and specialized support services, including availability on weekends. These service promises show how much we care about making our customers happy and running a successful business.

Conclusion

Slip ring rotor motors represent the optimal solution for enhancing crusher performance through their superior starting characteristics, variable speed capabilities, and robust construction. The combination of high starting torque, controlled acceleration, and adjustable operational parameters enables crushers to operate more efficiently while reducing mechanical stress and energy consumption. XCMOTOR's comprehensive motor solutions, backed by expert technical support and reliable manufacturing processes, provide the foundation for improved crusher operations across diverse industrial applications. The investment in quality slip ring rotor motor technology delivers measurable returns through enhanced productivity, reduced maintenance costs, and extended equipment lifespan.

Frequently Asked Questions

Q1: What are the primary advantages of using slip ring rotor motors in crusher applications?

A: Slip ring rotor motors provide exceptional starting torque up to 280% of rated torque, controlled acceleration characteristics, and variable speed operation. These features enable crushers to handle heavy initial loads, reduce mechanical stress during startup, and optimize performance for different material types while maintaining energy efficiency.

Q2: How do maintenance requirements compare between slip ring rotor motors and standard motors?

A: While slip ring rotor motors require additional attention to brush and slip ring maintenance, their overall maintenance requirements remain manageable with proper scheduling. Regular inspection of brushes, slip rings, and bearings ensures optimal performance, and the availability of premium bearing options from SKF, NSK, and FAG manufacturers enhances reliability.

Q3: Can slip ring rotor motors integrate with modern control systems and VFDs?

A: Yes, slip ring rotor motors are fully compatible with variable frequency drives and modern control systems. This integration enables precise speed control, energy savings, and advanced operational features including remote monitoring and automated parameter adjustment based on crushing conditions.

Partner with XCMOTOR for Superior Crusher Motor Solutions

XCMOTOR stands ready to transform your crusher operations through our advanced slip ring rotor motor technology and comprehensive support services. Our engineering team provides customized solutions tailored to your specific crushing applications, ensuring optimal performance and operational efficiency.

As a leading slip ring rotor motor manufacturer, we combine decades of experience with cutting-edge technology to deliver motor solutions that exceed industry standards. Our manufacturing processes incorporate state-of-the-art techniques including precision winding and vacuum pressure impregnation, guaranteeing superior product quality and extended service life.

Ready to enhance your crusher performance and operational efficiency? Our technical specialists are available to discuss your specific requirements and recommend the optimal motor configuration for your application. Contact us at xcmotors@163.com to schedule a consultation or request detailed technical specifications.

References

- Chapman, Stephen J. "Electric Machinery Fundamentals, Fifth Edition." McGraw-Hill Education, 2012. Chapter 8: Induction Motors.

- Naidu, M. S., and S. Kamakshiah. "Introduction to Electrical Engineering." Tata McGraw-Hill, 2004. Section on Wound Rotor Induction Motors.

- Sen, P.C. "Principles of Electric Machines and Power Electronics, Third Edition." John Wiley & Sons, 2013. Chapter 6: Induction Machine Applications.

- Boldea, Ion, and Syed A. Nasar. "The Induction Machines Design Handbook, Second Edition." CRC Press, 2010. Chapter 12: Wound Rotor Motors.

- Hughes, Austin, and Bill Drury. "Electric Motors and Drives: Fundamentals, Types and Applications, Fourth Edition." Newnes, 2013. Chapter 7: Induction Motor Drives.

- Wildi, Theodore. "Electrical Machines, Drives and Power Systems, Sixth Edition." Pearson, 2013. Chapter 15: Three-Phase Induction Motors.