Sourcing the right VFD duty motor supplier requires careful evaluation of technical capabilities, service quality, and long-term reliability. Modern industrial operations depend on variable frequency drive motors that deliver consistent performance while maintaining energy efficiency across diverse applications. Successful B2B procurement teams understand that selecting qualified suppliers directly impacts operational uptime, cost control, and compliance with international standards in today's competitive manufacturing landscape.

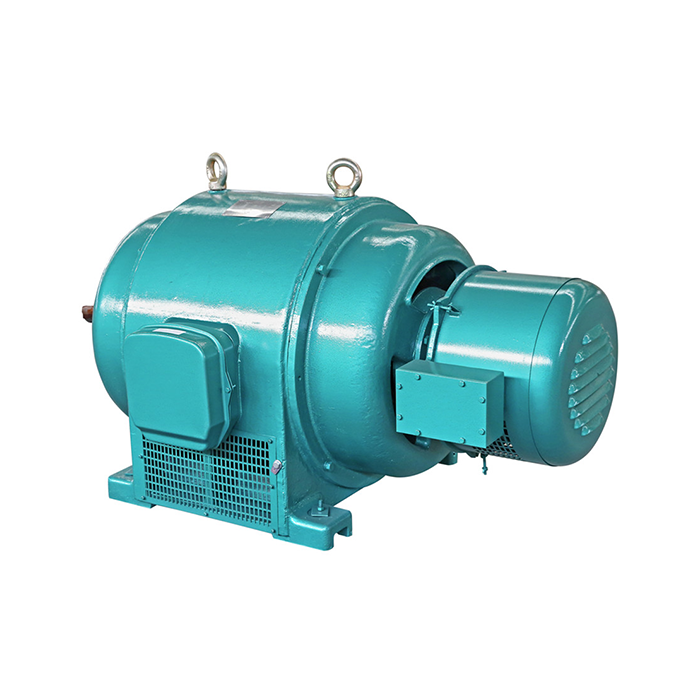

Series:YVFE5

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding VFD Duty Motors: Key Features and Applications

What Is a VFD Duty Motor? Definition and Technical Overview

VFD duty motors are engineered for inverter operation, featuring reinforced insulation, robust bearings, and balanced rotors to withstand voltage spikes, harmonics, and thermal stress during variable speed control.

Typical Applications of VFD Duty Motors in Industry

These motors are widely used in industrial automation, conveyors, robotics, HVAC systems, pumps, fans, and compressors, where precise speed regulation improves efficiency, process stability, and overall energy performance.

Advantages Over Standard Motors: Efficiency, Performance, and Reliability

Compared with standard motors, VFD Duty Motor designs deliver wider speed ranges, improved thermal management, longer bearing life, and reduced maintenance, ensuring reliable performance under demanding variable frequency operation.

How VFD Duty Motors Work with Variable Frequency Drives?

Variable recurrence drives change over settled AC control into flexible recurrence yield, empowering exact control of engine speed and torque whereas optimizing effectiveness and decreasing electrical and mechanical stress.

Common Causes of Overheating and How to Avoid Them

Overheating regularly stems from low-speed cooling restrictions, voltage lopsidedness, or sounds. Legitimate engine determination, satisfactory ventilation, correct drive settings, and schedule observing offer assistance avoid heat damage.

Comparing VFD Duty Motors: Core Criteria for Supplier Selection

VFD Duty Motor vs Standard Motor and Inverter Duty Motor: What You Need to Know

Understanding engine classifications makes a difference when acquisition groups make educated choices based on application necessities. Standard engines need the specialized cover and warm assurance fundamental for variable frequency operation, whereas inverter obligation engines give essential VFD compatibility without the advanced features of true variable frequency designs.

True VFD engines consolidate progressed highlights counting fortified bearing frameworks, improved cooling capabilities, and specialized winding plans that optimize execution over wide speed ranges. These engines meet stricter electrical and mechanical requirements compared to standard or essential inverter obligation alternatives.

Evaluating Torque Performance and Energy Efficiency Among Suppliers

Torque characteristics change altogether among providers, influencing framework execution and vitality utilization. Premium engines keep up reliable torque yield over speed ranges, while minimizing misfortunes through progressed attractive circuit plan and accuracy in manufacturing processes.

Energy proficiency evaluations give important comparison measurements, in spite of the fact that genuine execution depends on particular working conditions and drive system integration. Providers ought to give nitty gritty execution bends and effectiveness information over the operational speed range to empower exact framework plan and energy consumption calculations.

Key Specifications to Review: Brands, Models, Certifications

Critical determinations incorporate control evaluations from 0.75kW to 1000kW, voltage compatibility over 380V, 400V, 415V, and 660V frameworks, and recurrence ranges crossing 5Hz to 100Hz for greatest application adaptability. Security levels must meet IP55 benchmarks at least, with higher evaluations accessible for challenging natural conditions.

International certification compliance guarantees worldwide compatibility and administrative acknowledgment. Engines ought to meet IEC dimensional guidelines while consolidating premium bearing frameworks from built up producers to guarantee long-term reliability and serviceability worldwide.

Warranty, After-Sales Support, and Maintenance Tips for Longevity

Comprehensive guarantee scope illustrates provider certainty in item quality while securing acquisition investments. Viable after-sales support incorporates specialized help, save parts accessibility, and field service capabilities that minimize downtime during maintenance activities.

Maintenance prerequisites shift based on working conditions and obligation cycles. Normal review plans ought to address bearing grease, cover resistance testing, and thermal checking to maximize gear life expectancy and keep up top execution all through the service period.

Global Sourcing Checklist for VFD Duty Motors

Identifying Reliable Global Suppliers: What to Look For

Reliable providers appear demonstrated fabricating frameworks, reliable quality control, full testing capabilities, and solid designing bolster. Clear documentation and application direction demonstrate encounter serving mechanical clients and long-term obtainment reliability.

Assessing Lead Times, Bulk Order Capability, and Customization Options

Capable providers adjust standard stock with adaptable generation capacity, supporting bulk orders and customization. Designing versatility permits voltage, mounting, or include adjustments without compromising quality, conveyance soundness, or execution expectations.

Pricing Transparency and Total Cost of Ownership Considerations

Effective evaluation considers total lifecycle cost, not unit price alone. Transparent pricing, energy efficiency, maintenance requirements, and logistics determine long-term value, especially when selecting high-efficiency VFD Duty Motor solutions.

Regional Distributors vs Direct Manufacturers: Pros and Cons

Distributors offer faster delivery and local support, while direct manufacturers provide better pricing, deeper customization, and technology access. Optimal sourcing depends on order size, technical complexity, and project timelines.

Verifying Compliance with International Standards and Certifications

Global sourcing requires verified compliance with IEC and regional safety standards. Complete certification documents, test reports, and declarations ensure smooth approval, installation, and regulatory acceptance across international markets.

Enterprise Introduction and Product-Service Information

Company Overview: Experience in Supplying High-Quality VFD Duty Motors

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing comprehensive power equipment solutions tailored to industrial automation, HVAC systems, and energy applications. Our experience spans decades of serving manufacturing, process control, and automation sectors where reliable motor performance directly impacts operational success.

XCMOTOR maintains rigorous quality standards through advanced manufacturing processes and comprehensive testing procedures that ensure consistent performance across diverse operating conditions. Our engineering team collaborates with clients to develop optimized solutions that meet specific application requirements while maintaining cost-effectiveness and reliability.

Product Range: Custom and Standard VFD Duty Motors Tailored for Global Markets

Our YVFE5 product line encompasses power ranges from 0.75kW to 1000kW with frequency capabilities spanning 5Hz to 100Hz, enabling precise speed control across demanding industrial applications. Standard voltage options include 380V, 400V, 415V, and 660V configurations with customization available to meet specific system requirements.

Advanced features include IE5 premium efficiency ratings, IP55 protection as standard with higher ratings available, and Class F insulation with Class H options for extreme operating conditions. Precision-balanced rotors ensure smooth operation while reinforced bearing systems accommodate the most demanding duty cycles in industrial environments.

Service Excellence: Technical Support, After-Sales Service, and Flexible Delivery Options

XCMOTOR provides comprehensive technical support throughout the procurement and installation process, including application guidance, specification development, and system integration assistance. Our engineering team remains available to address technical questions and provide ongoing support throughout the equipment lifecycle.

After-sales service includes maintenance guidance, troubleshooting assistance, and spare parts availability to minimize downtime and maintain peak performance. Flexible delivery options accommodate urgent requirements while maintaining our commitment to quality and customer satisfaction across global markets.

Commitment to Energy Efficiency and Sustainable Industrial Solutions

Sustainability drives our item improvement activities, centering on energy-efficient plans that diminish operational costs whereas minimizing natural affect. Our engines join progressive materials and fabrication procedures that optimize execution, while amplifying benefit life expectancy and lessening upkeep requirements.

Energy proficiency advancements provide quantifiable benefits through decreased control utilization, lower cooling necessities, and improved system performance. These focal points align with worldwide sustainability activities while generating substantial revenue funds that legitimize speculation in premium engine technology.

Conclusion

Successful VFD duty motor procurement requires orderly assessment of provider capabilities, item determinations, and long-term back-up services. The checklist approach empowers acquisition groups to make educated choices that adjust starting costs with lifecycle esteem whereas guaranteeing operational stability and compliance with universal measures. Cutting-edge mechanical operations depend on variable speed engine innovation that conveys reliable execution over assorted applications, making provider choice basic for maintained operational victory. XCMOTOR stands prepared to bolster your acquisition goals through demonstrated encounter, comprehensive product offerings, and uncommon benefit capabilities that address the advancing needs of worldwide mechanical markets.

Frequently Asked Questions

Q1: What factors distinguish a VFD duty motor from a standard motor?

A: Variable recurrence engines highlight improved separator frameworks planned to handle voltage spikes and sounds from drive frameworks, strengthened bearing gatherings for variable speed operation, and specialized warm administration that anticipates overheating amid low-speed conditions. Standard engines need these defensive highlights and may encounter untimely disappointment when used with recurrence drives.

Q2: How to troubleshoot common issues like overheating in VFD duty motors?

A: Overheating regularly comes about from insufficient cooling at low speeds, voltage awkward nature, or over the top consonant substance. Arrangements incorporate confirming legitimate ventilation, checking drive programming for ideal parameters, checking bearing temperatures, and guaranteeing voltage adjustment over all stages. Normal upkeep plans offer assistance in distinguishing potential issues before they cause gear damage.

Q3: What lead times and minimum order quantities can be expected from global suppliers?

A: Lead times change from 2-4 weeks for standard models to 8-12 weeks for customized setups, depending on provider capacity and detail complexity. Least arranged amounts ordinarily run from single units for standard items to 10-50 units for customized plans, in spite of the fact that set up providers frequently suit littler amounts for beginning trials or crisis replacements.

Partner with XCMOTOR for Premium VFD Duty Motor Solutions

XCMOTOR delivers exceptional variable frequency motor solutions backed by decades of engineering excellence and comprehensive customer support. Our YVFE5 product line offers power ranges from 0.75kW to 1000kW with advanced features including IE5 efficiency ratings, robust IP55 protection, and flexible frequency ranges up to 100Hz. Experience the reliability and performance that industrial leaders trust through our commitment to quality, innovation, and customer satisfaction. Contact our technical team to discuss your specific requirements and discover how our VFD duty motor supplier expertise can optimize your operational performance. Reach out to us today at xcmotors@163.com to explore our comprehensive product catalog and request customized solutions for your industrial applications.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Part 30-1: Efficiency Classes of Line Operated AC Motors." IEC Standard 60034-30-1, 2014.

2. Institute of Electrical and Electronics Engineers. "IEEE Recommended Practice for Motor Protection in Industrial and Commercial Power Systems." IEEE Standard 242, 2018.

3. National Electrical Manufacturers Association. "Motors and Generators - Application Guide for AC Adjustable Speed Drive Systems." NEMA Standards Publication MG 1, 2016.

4. American Society of Heating, Refrigerating and Air-Conditioning Engineers. "Energy Efficient Design of Variable Speed Drive Systems." ASHRAE Technical Guidelines, 2019.

5. Industrial Electronics Society. "Variable Frequency Drives in Industrial Applications: Performance Optimization and Energy Efficiency." IEEE Industry Applications Magazine, 2020.

6. International Organization for Standardization. "Quality Management Systems - Requirements for Motor Manufacturing and Testing." ISO 9001:2015 Application Guidelines for Electrical Equipment, 2017.