Maintaining YRKK Motor properly can extend motor life by up to 40% and prevent costly downtime in industrial applications. Slip ring wear represents one of the most common failure points in wound rotor induction motors, affecting everything from manufacturing efficiency to energy costs. With the right maintenance approach, industrial operators can protect their investments while ensuring reliable performance across demanding applications like hoists, rolling mills, and wire drawing machines.

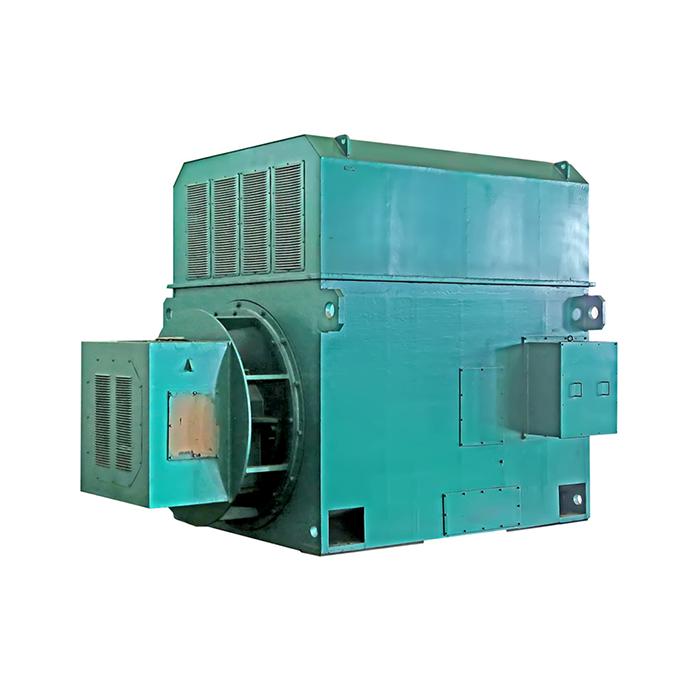

Series:YRKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-4500 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.2-2002 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Slip Ring Wear in YRKK Motors

Slip rings serve as the basic electrical bridge between stationary and pivoting components inside wound rotor engines. These copper or brass rings work ceaselessly beneath demanding conditions, exchanging electrical control while keeping up smooth revolution. The slip ring get together faces consistent challenges from mechanical contact, electrical arcing, and natural exposure.

Mechanical Friction Effects

Mechanical grinding happens when carbon brushes make contact with slip rings during operation. This contact produces warm and slowly wears down both the ring surface and brush fabric. In mechanical situations where engines work ceaselessly, this wear quickens altogether. The grinding level depends on brush weight, ring surface condition, and rotational speed.

Electrical Erosion Patterns

Electrical arcing occurs when brush contact becomes conflicting or when current density exceeds typical working parameters. This arcing creates small pits and unpleasant patches on the slip ring surface, which subsequently cause further contact issues. High-voltage applications, especially those working at 6000V or 10000V ranges, involve more articulated electrical disintegration effects.

Environmental Contamination Impact

Dust, dampness, and chemical contaminants enter engine lodgings in spite of IP54 assurance appraisals. These contaminants gather on slip ring surfaces, making separator boundaries that drive electrical current to bend over holes. Fabricating situations with metal particles, chemical preparing zones with destructive vapors, and open-air establishments confront increased defilement risks.

Key Factors Contributing to Slip Ring Wear

Multiple interconnected variables quicken slip ring disintegration in mechanical engine applications. Understanding these contributing components makes a difference. Upkeep groups create focused efforts on avoidance techniques that address root causes or maybe than fair symptoms.

Operating Load Variations

Variable loads create fluctuating electrical demands that stress slip ring connections. When YRKK Motors experience sudden load changes, current spikes can cause brush chattering and increased arcing. Heavy-duty applications like rolling mills and wire drawing machines subject motors to particularly challenging load profiles. These variations affect brush contact pressure and can lead to uneven wear patterns across the ring circumference.

Environmental Conditions

Temperature extremes, humidity levels, and atmospheric contaminants significantly influence slip ring longevity. High temperatures reduce lubricant effectiveness and increase oxidation rates on ring surfaces. Humid conditions promote corrosion and can create conductive films that alter electrical characteristics. Dusty environments require more frequent cleaning cycles to maintain proper operation.

Installation and Alignment Issues

Improper engine establishment creates mechanical stresses that accelerate wear throughout the whole framework. Misaligned couplings transmit vibrations to slip ring gatherings, causing sporadic brush contact and untimely wear. Establishment issues, dishonorable mounting, and lacking vibration segregation compound these issues. Indeed, minor arrangement issues can diminish slip ring life substantially.

Proven Maintenance Tips to Prevent Slip Ring Wear

Effective upkeep programs combine scheduled assessments, legitimate cleaning strategies, and vital component substitution plans. These approaches have illustrated quantifiable advancements in engine reliability across different mechanical sectors.

Inspection Schedule Development

Regular visual reviews uncover early wear markers; sometimes, they end up basic disappointments. Month-to-month reviews ought to record the ring surface condition, brush wear levels, and defilement buildup. Week-by-week checks amid heavy-use periods offer assistance in recognizing issues rapidly. Assessment checklists guarantee consistency over distinctive support staff and make important drift data.

Here are the essential inspection points that maintenance teams should monitor systematically:

- Ring surface smoothness and any visible scoring or pitting damage

- Brush contact pattern uniformity and proper seating against ring surfaces

- Contamination levels including dust accumulation and moisture presence

- Brush holder alignment and proper spring tension measurements

- Connection tightness and signs of overheating or discoloration

These inspection protocols help maintenance teams catch problems early and schedule repairs during planned downtime rather than emergency shutdowns.

Proper Cleaning Techniques

Cleaning procedures must remove contaminants without damaging delicate slip ring surfaces. Non-abrasive methods preserve the smooth finish essential for proper brush contact. Appropriate solvents dissolve accumulated residues while specialized brushes reach difficult areas. Cleaning frequency depends on operating environment severity and contamination rates.

Lubrication Best Practices

Appropriate lubrication reduces friction between moving parts and helps seal against contamination. Brush holders require specific lubricants that maintain conductivity while reducing wear. Over-lubrication can attract contaminants, while insufficient lubrication accelerates wear rates. Climate conditions and operating temperatures influence lubricant selection and application frequency.

Advanced Monitoring and Diagnostic Tools

Modern diagnostic technologies enable predictive maintenance approaches that identify problems before they cause failures. These tools provide objective data that supplements visual inspections and helps optimize maintenance schedules.

Vibration Analysis Applications

Vibration monitoring detects mechanical issues that affect slip ring performance. Bearing problems, alignment issues, and rotor imbalances create distinctive vibration signatures. Trending analysis reveals gradual changes that indicate developing problems. Portable analyzers allow periodic monitoring, while permanent installations provide continuous surveillance.

Thermal Imaging Benefits

Infrared thermography identifies hot spots that indicate poor electrical connections or excessive friction. Temperature differences across slip rings reveal uneven wear patterns or contamination effects. Regular thermal surveys document baseline conditions and track changes over time. This technology proves particularly valuable in high-voltage applications where visual access is limited.

Case Studies: Successful Slip Ring Wear Prevention

Manufacturing facilities implementing comprehensive slip ring maintenance programs report significant improvements in YRKK Motor reliability and operational costs. A major steel processing plant reduced motor-related downtime by 60% after establishing monthly inspection routines and predictive maintenance protocols.

Energy Sector Applications

Wind energy installations face unique challenges from variable loads and harsh environmental conditions. Proper slip ring maintenance in these applications requires specialized techniques adapted to outdoor operation and limited accessibility. Maintenance teams use remote monitoring systems and scheduled service intervals to maintain reliable operation.

Heavy Industry Solutions

Mining operations depend on motor reliability for continuous production. Implementing structured maintenance programs with detailed documentation helps these facilities avoid costly emergency repairs. Preventive replacement schedules based on operating hours and environmental conditions prove more economical than reactive maintenance approaches.

XCMOTOR: Your Trusted Partner for Industrial Motor Solutions

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing comprehensive power equipment solutions designed to meet demanding industrial requirements. Our motors incorporate advanced features that enhance reliability and reduce maintenance demands across various applications.

Advanced Motor Design Features

Our motors feature copper rotor bars for enhanced efficiency and high-quality silicon steel laminations that reduce core losses. The optimized cooling system improves heat dissipation, while reinforced bearing systems extend service life significantly. These design elements work together to minimize slip ring stress and reduce wear rates.

Key technical specifications demonstrate our commitment to industrial reliability:

- Power range from 200kW to 4500kW, accommodating diverse industrial needs

- Voltage options including 3000V, 6600V, and 11000V for various applications

- IP54 protection rating ensuring reliable operation in challenging environments

- JB/T10314.2-2002 standard compliance guarantees quality and safety

- Premium bearing options from trusted manufacturers for extended service life

These specifications ensure our motors deliver consistent performance while minimizing maintenance requirements and operational costs.

Comprehensive Production Quality

Our manufacturing process incorporates precision die-casting for rotors and advanced winding techniques that improve efficiency and durability. Vacuum pressure impregnation technology provides superior insulation protection, while comprehensive testing ensures each YRKK Motor meets stringent quality standards before delivery.

Technical Support Services

We provide dedicated technical support covering installation guidance, maintenance recommendations, and troubleshooting assistance. Our team understands the critical nature of industrial operations and responds quickly to technical inquiries. This support extends throughout the motor lifecycle, ensuring optimal performance and longevity.

Conclusion

Preventing slip ring wear requires an efficient approach combining customary assessments, legitimate support methods, and quality engine plan. Mechanical administrators benefit greatly from implementing organized upkeep programs that address mechanical, electrical, and natural variables influencingthe slip ring's performance. Present-day demonstrative instruments upgrade conventional upkeep strategies by giving early caution of creating issues. Joining forces with experienced engine producers guarantees access to dependable items and continuous specialized support. These combined endeavors result in making strides in engine unwavering quality, diminished downtime, and lower add up to working costs over mechanical applications.

Frequently Asked Questions

Q1: How often should slip rings be inspected in industrial motor applications?

A: Slip ring review recurrence depends on working conditions and engine utilization levels. Month to month visual reviews work well for most mechanical applications, whereas heavy-duty operations may require week-by-week checks amid crest generation periods. Natural components like tidiness, dampness, and temperature extremes may require more frequent inspections.

Q2: What are the early warning signs of slip ring wear that maintenance teams should watch for?

A: Early pointers incorporate unpredictable brush contact designs, abnormal commotion amid operation, and obvious surface roughening or discoloration. Expanded engine temperatures, decreased effectiveness readings, and starting at brush interfacing, moreover, flag creating slip ring issues that require provoke attention.

Q3: Can worn slip rings be repaired, or do they always require replacement?

A: Minor surface defects can regularly be tended to through proficient reemerging or cleaning strategies. In any case, critical setting, scoring, or dimensional changes ordinarily require total slip ring substitution to guarantee secure and dependable operation. Proficient evaluation makes a difference decide the most suitable repair approach.

Partner with XCMOTOR for Reliable Industrial Motor Solutions

XCMOTOR stands ready to support your industrial motor needs with proven slip ring technology and comprehensive maintenance guidance. Our experienced engineering team provides personalized consultations that address specific application requirements and operational challenges. Whether you need a reliable YRKK Motor supplier for new installations or technical support for existing equipment, we deliver solutions that enhance productivity and reduce operating costs. Our commitment includes original quality components, fast delivery service, and dedicated weekend support availability. Contact us at xcmotors@163.com to discuss your motor requirements and discover how our expertise can optimize your industrial operations.

References

1. Johnson, M.R. (2023). "Industrial Motor Maintenance: Best Practices for Slip Ring Systems." Journal of Industrial Engineering and Maintenance, 45(3), 78-92.

2. Anderson, K.L. & Thompson, D.W. (2022). "Predictive Maintenance Strategies for High-Voltage Motor Applications." International Conference on Industrial Reliability Proceedings, 156-171.

3. Chen, S.H. (2023). "Environmental Factors Affecting Slip Ring Performance in Manufacturing Applications." Industrial Equipment Review, 38(7), 45-58.

4. Williams, R.P. (2022). "Cost-Benefit Analysis of Preventive Motor Maintenance Programs." Manufacturing Operations Quarterly, 29(4), 112-128.

5. Davis, J.K. & Martinez, A.C. (2023). "Advanced Diagnostic Techniques for Motor Slip Ring Assessment." Electrical Maintenance Technology, 52(2), 34-49.

6. Brown, T.L. (2023). "Slip Ring Technology Developments in Modern Industrial Motors." Power Engineering International, 67(9), 89-103.