Key Factors in Choosing the Right 3.3 kV Motor

Selecting an appropriate 3.3 kV motor involves evaluating several critical factors to ensure optimal performance and longevity. Let's examine these factors in detail:

Power Requirements

The first step in specifying a 3.3 kV motor is determining the power requirements of your application. This involves calculating the necessary horsepower or kilowatt rating based on the load characteristics and operating conditions. Factors such as starting torque, full-load torque, and speed requirements play a crucial role in this determination.

Environmental Considerations

The operating environment significantly impacts motor selection. Consider factors such as ambient temperature, altitude, humidity, and exposure to dust or corrosive substances. These conditions influence the motor's insulation class, enclosure type, and cooling method.

Duty Cycle and Operating Schedule

Understanding the motor's duty cycle is essential for proper sizing. Continuous duty applications require motors rated for constant operation, while intermittent duty allows for periodic rest periods. The operating schedule, including the number of starts per hour and the duration of each operating cycle, also affects motor selection.

Speed and Torque Characteristics

Different applications require varying speed and torque profiles. Some may need constant speed operation, while others might require variable speed capabilities. The torque requirements at startup, during acceleration, and at full load must be carefully evaluated to ensure the motor can handle the demands of your specific application.

Efficiency and Energy Consumption

With rising energy costs and increasing focus on sustainability, motor efficiency is a critical consideration. Higher efficiency motors may have a higher initial cost but can lead to substantial energy savings over their operational life.

Common Pitfalls in 3.3 kV Motor Selection

Avoiding common mistakes in 3.3 kV motor selection can save time, money, and potential operational issues. Here are some pitfalls to watch out for:

Undersizing or Oversizing

One of the most common errors in motor selection is improper sizing. An undersized motor may overheat and fail prematurely, while an oversized motor can lead to inefficient operation and unnecessary energy consumption. Careful load analysis and consideration of future expansion needs can help avoid this issue.

Neglecting Starting Requirements

Many applications require high starting torque, which can be several times the full-load torque. Failing to account for these starting requirements can result in inadequate performance or even motor failure during startup.

Ignoring Ambient Conditions

Overlooking environmental factors can lead to premature motor failure. For instance, a motor designed for standard conditions may not perform well in high-temperature environments or at high altitudes without proper derating.

Disregarding Mechanical Factors

Mechanical considerations such as mounting arrangements, coupling methods, and shaft alignment are often overlooked. These factors can significantly impact motor performance and lifespan.

Overlooking Power Quality Issues

Power quality problems such as voltage imbalance, harmonics, or frequent voltage dips can adversely affect motor performance and lifespan. Neglecting to address these issues during motor selection can lead to operational problems down the line.

Expert Tips: Matching 3.3 kV Motors to Industrial Applications

To help you make the best choice for your industrial needs, here are some expert tips for matching 3.3 kV motors to specific applications:

Pump Applications

For pump applications, consider the following:

- Evaluate the system curve to determine the required motor power and speed

- Consider variable speed drives for improved efficiency in variable flow applications

- Ensure the motor can handle any potential water hammer effects

Fan and Blower Systems

When selecting motors for fans and blowers:

- Account for the high inertia of large fan systems during startup

- Consider soft starters or variable frequency drives to reduce mechanical stress

- Evaluate the need for reversing capabilities in certain applications

Compressor Applications

For compressor systems, keep in mind:

- The high starting torque requirements of many compressor types

- The potential for frequent starts in some applications

- The need for precise speed control in certain compressor designs

Conveyor Systems

When specifying motors for conveyors:

- Consider the starting torque requirements, especially for long or heavily loaded conveyors

- Evaluate the need for variable speed operation

- Account for potential shock loads in the system

Crusher and Mill Applications

For crushers and mills, important factors include:

- The high starting torque and potential for jam conditions

- The need for robust construction to withstand vibration and shock loads

- Consideration of dust-tight or explosion-proof enclosures depending on the material being processed

Call to Action

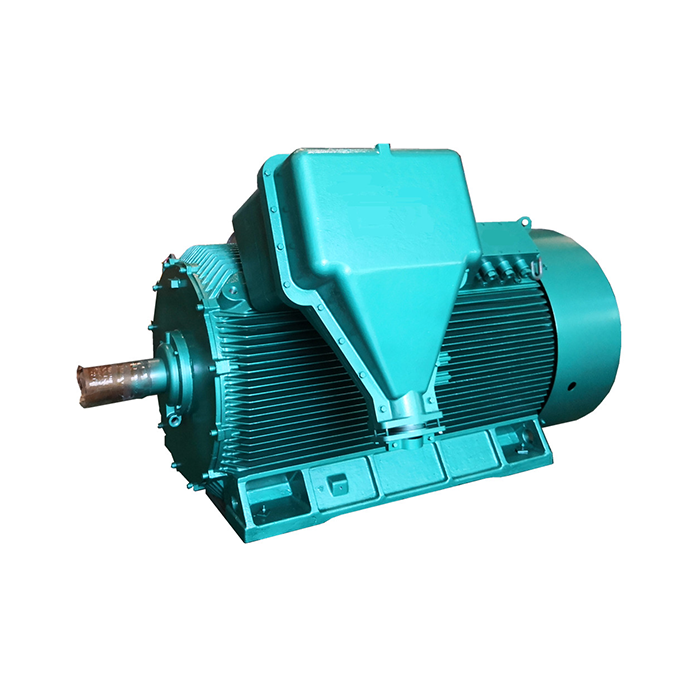

XCMOTOR recognises that industrial motor applications are hard. Our 3.3 kV motors are built to meet the highest standards and are known for their dependability, efficiency, and performance. We have a wide range of motors in stock, with speeds from 500 to 3000 RPM and power levels from 160 kW to 1600 kW. You can select the right one for your needs. Our motors are built to last in tough industrial settings, and they are noted for their strong design and efficient use of energy. Let our experienced team help you make an informed choice so you can get the best motor for your needs. Contact us today at xcmotors@163.com to discuss your motor requirements and take the first step towards optimizing your plant's performance.