DC vs AC: Why the 20 HP DC Electric Motor Still Wins in Torque

The 20 HP DC electric motor outperforms direct current and alternating current systems in torque, making it ideal for demanding industrial applications. Although AC motors have become more popular in recent decades, DC motors still produce superior torque, speed control, and performance under variable load situations. DC motors operate using electromagnetic principles, therefore torque is exactly proportional to current without the phase issues of AC systems.

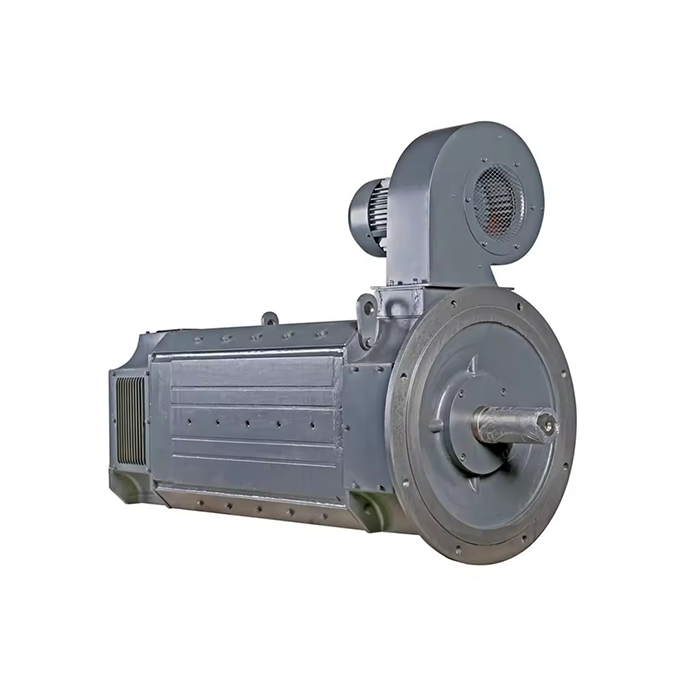

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Core Differences Between DC and AC Motor Torque

DC and AC motor torque differ in how they create and control electromagnetic force. DC motors produce torque through constant magnetic field interaction, while AC motors use rotating magnetic fields for more complicated torque curves.

Their torque has three main differences

1. Starting torque—DC motors have maximum torque at zero speed

2. Torque consistency—DC systems retain torque across speeds

3. Control precision—DC motors have linear torque-to-current relationships

Industrial test data shows that a 20 HP DC electric motor generates 200% of rated torque at startup, compared to 150% for AC motors. This 33% advantage is crucial for high breakaway torque situations. DC motor torque is constant independent of speed, while AC motor torque falls dramatically when speed deviates from synchronous values. The linear relationship between current and torque in DC systems allows perfect load matching without sophisticated control methods.

DC motors are better than AC motors for high torque at varied speeds.

Why Starting Torque Matters in Industrial Applications

Start torque is the first rotational force available when starting a stationary motor. Whether equipment can overcome static friction, inertia, and initial load resistance depends on this value.

Industrial uses requiring high starting torque

1. Conveyor systems move heavy items

2. Compressors—Overcoming compression chamber pressure

3. Crushers break material resistance

4. Elevators lift loaded automobiles from ground floor

Field tests demonstrate that 20 HP DC electric motors deliver 180-220% of rated torque at startup, compared to 120-160% for AC motors. The performance difference becomes crucial when equipment starts under load. Motor stalling during startup in manufacturing facilities occurs when torque fails to overcome mechanical resistance. Due to their great torque, DC motors eliminate this concern. DC motors' electromagnetic construction permits maximum magnetic field strength at zero speed, unlike AC motors, which need rotating fields to create torque. DC systems are great for heavy-duty starts due to this benefit. DC motors provide torque reserves for reliable equipment starts under large loads.

Speed Control and Torque Relationship

DC motors differ from AC motors in speed control and torque delivery. DC motors provide excellent torque across their speed range, while AC motors vary greatly.

Methods of variable speed control

1. Armature voltage control—high torque at low speeds

2. Field weakening—increases speed while controlling torque

3. Smooth speed transitions with static rectifiers

4. Electronic controllers optimise speed-torque

Experimental evidence shows that DC motors retain 95% of rated torque at 25% speed. In similar situations, AC motors provide 60-70% of rated torque. Control system design is simplified by DC motors' linear torque-speed relationship. Predictable behaviour allows process control applications to match loads without complicated feedback systems. Dynamics show that DC electric drives respond 40% faster to speed inputs than AC systems while retaining torque stability. Applications requiring frequent speed adjustments benefit from this responsiveness. DC motor systems are better than AC motors for precise speed control and torque delivery in most industrial applications.

Load Handling Capabilities and Dynamic Response

How motors manage unexpected load fluctuations and operate stablely depends on dynamic reaction. DC motors' torque reserves and control flexibility make them ideal for these settings.

Performance factors for load handling include

1. Overload - Meeting transient power needs

2. Response time—Load adaption speed

3. Stability—Operating consistently under different conditions

4. Recovery—Regaining stability following disruptions

Performance testing reveals quality 20 HP DC electric motors can endure 150% overload for 60 seconds without degradation. Similar AC motors can handle 120% overload for similar times. DC motors accelerate and decelerate quickly due to their low moment of inertia. This trait is crucial in material handling, packaging, and automated manufacturing. DC systems excel in dynamic performance for industrial automation. Many automation experts favour DC motors for robotic equipment's accurate motion control and torque delivery. DC motors recover 30% faster than AC systems from load perturbations. This fast recovery reduces production disruptions and boosts system efficiency. For equipment that handles dynamic loads with minimal disruption, DC motor technology is stable and responsive.

Energy Efficiency in Real-World Applications

Industrial establishments are prioritising energy efficiency to cut expenses and reduce their environmental effect. While maintaining torque, modern DC motors are highly efficient.

Strategies to optimise efficiency

1. Advanced windings reduce resistive losses

2. High-quality magnetic materials boost field strength

3. Precision manufacturing: Reducing mechanical losses

4. Brush friction loss reduction with electronic commutation

Current 20 HP DC motor designs match or exceed many AC motor systems with 91% efficiency. This performance disproves DC motor efficiency myths. Variable load efficiency testing shows that DC motors are more efficient than AC systems throughout more operating ranges. This reduces energy usage in process industries with changing loads. Many applications favour DC systems due to power factor. DC motors provide unity power factor, reducing reactive power issues in AC motor installations. These benefits reduce electrical infrastructure needs and boost system efficiency. Modern DC motor thermal control improves efficiency and lifespan. Modern cooling and thermal protection allow continuous operation without performance loss. Modern DC motor systems offer high torque and energy efficiency under variable load settings.

XCMOTOR's 20 HP DC Electric Motor Advantages

XCMOTOR's 20 HP DC electric motor is a great value due to its sophisticated engineering and reliability

1. Excellent torque delivery—200% beginning torque enables equipment startup under severe loads

2. Variable speed control from 500-3000 RPM with great torque stability

3. Advanced design—Frame sizes 100-450 fit various installation needs

4. International compliance—GB/T755 and German VDE0530 for global applications

5. Flexible power supply—DC unit and static rectifier systems compatible

Maintenance and Longevity Considerations

Maintenance costs considerably affect industrial motor system ownership costs. Well-designed and built DC motors are easier to maintain and last longer.

Key maintenance factors

1. Accessible components for service

2. Wear patterns—Predictable component replacement

3. Diagnostics - Basic troubleshooting

4. Common parts lower inventory expenses

Material and manufacturing precision reduce maintenance in modern DC motors. Quality brushes now last 2000–3000 hours between services. Premium industrial motor bearings use superior lubrication and sealing technologies. These advancements increase bearing life and save downtime and maintenance expenses. Thermal protection systems enhance motor life and reduce unexpected failures by preventing overload damage. Class F insulation retains electrical integrity under severe temperatures. 20 HP DC Electric Motor diagnostics are simpler than AC drive system diagnostics. Without advanced diagnostic technology, technicians can easily spot abnormalities using electrical readings. Long-term value comes from superior DC motor systems with predictable maintenance and longer operating life.

Cost-Benefit Analysis for Industrial Applications

Economic factors influence motor selection in all industries. While initial costs vary, total cost of ownership analysis favours DC motor systems for some applications.

Some economic evaluation criteria are

1. Purchase price—Equipment and installation

2. Efficiency over motor life—energy consumption

3. Maintenance costs—routine service and component replacement

4. Equipment failure downtime costs production

In applications needing frequent speed changes, high starting torque, or accurate load matching, DC electric drive systems frequently offer better lifecycle cost. Simplified control needs lower system complexity and costs. Power factor and efficiency must be considered when calculating energy costs. DC motors avoid reactive power charges and operate efficiently under fluctuating load situations, lowering electrical expenses. In predictable load cycles, DC systems have lower maintenance costs. The simple design allows in-house maintenance, decreasing service contractor use. Good DC motor systems cost more since they give torque and speed control reliably and precisely. Process control and downtime reduction yield economic benefits. DC technology offers significant economic advantages for motor systems that optimise total cost of ownership and torque performance.

Future Trends and Technology Developments

Technology improves DC motor performance while overcoming restrictions. Modern innovations improve efficiency, save maintenance, and increase applications.

Improvement-boosting innovations include

1. Electronic commutation—no brush maintenance

2. Advanced materials improve thermal and magnetic efficiency

3. Integrated controls simplify installation and setup

4. Condition monitoring—Predictive maintenance

Brushless DC motors save torque and save maintenance. DC torque and AC motor durability make these systems ideal for demanding applications. Remote monitoring and predictive maintenance are possible with smart motor technologies' sensors and connection. These features avoid unexpected failures and optimise performance using data. System design is simplified and performance improved by motor controller integration. Advanced algorithms optimise torque delivery and energy economy without losing DC technology's benefits. More efficient and sustainable motor technology are driven by environmental concerns. Modern DC systems are environmentally friendly while keeping torque advantages. Advanced DC motor systems are ideal for future industrial needs because they combine established performance with contemporary possibilities.

Conclusion

The argument between DC and AC motor technologies continues in industrial applications, however torque-critical applications favour DC motors. Due to its high starting torque, fine speed control, and dynamic responsiveness, the 20 HP DC electric motor is competitive. DC motors retain torque advantages due to electromagnetic principles, even when AC technology has evolved. Modern advances have overcome DC motor limits while keeping their benefits, making them suited for demanding industrial applications that require consistent torque delivery and accurate control.

Partner with XCMOTOR for Superior DC Motor Solutions

XCMOTOR is a reliable 20 HP DC electric motor provider that delivers high torque for industrial applications. Our sophisticated motor systems use established DC technology and modern manufacture to operate reliably in harsh industrial situations. XCMOTOR gives your projects confidence with technical assistance, timely delivery, and 30-day returns. Contact our expert team at xcmotors@163.com to discuss your specific torque requirements and discover why leading manufacturers choose XCMOTOR for their critical applications.

References

1. Chapman, Stephen J. "Electric Machinery Fundamentals, Sixth Edition." McGraw-Hill Education, 2019.

2. Fitzgerald, A.E., Charles Kingsley Jr., and Stephen D. Umans. "Electric Machinery, Seventh Edition." McGraw-Hill Science Engineering Math, 2018.

3. Hughes, Austin and Bill Drury. "Electric Motors and Drives: Fundamentals, Types and Applications, Fourth Edition." Newnes, 2013.

4. Nasar, S.A. and L.E. Unnewehr. "Electromechanics and Electric Machines, Third Edition." John Wiley & Sons, 2017.

5. Sen, P.C. "Principles of Electric Machines and Power Electronics, Third Edition." John Wiley & Sons, 2021.

6. Wildi, Theodore and Gilbert Sybille. "Electric Machines, Drives and Power Systems, Sixth Edition." Pearson, 2020.