Best 4000 kW Motors for Heavy Industry

Buyers of 4000 kW motors for heavy industry applications require reliable, high-performance solutions that produce high power while operating efficiently. A quality 4000 kw motor powers large-scale manufacturing, mining, power generation, and water treatment processes. Advanced innovation and reliability provide these electric motors the torque and consistency needed for heavy-duty tasks. High-power industrial motors with advanced cooling systems, precision-balanced components, and energy-efficient designs decrease operational costs and boost productivity in harsh industrial conditions.

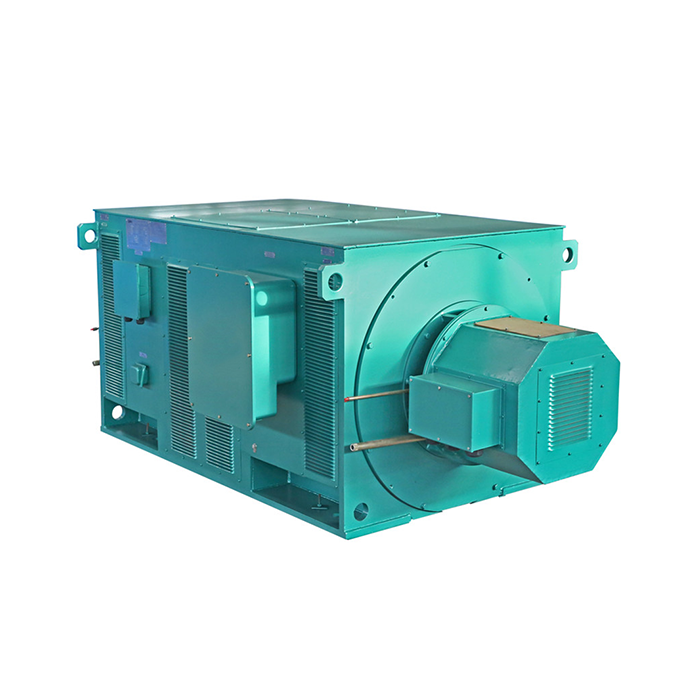

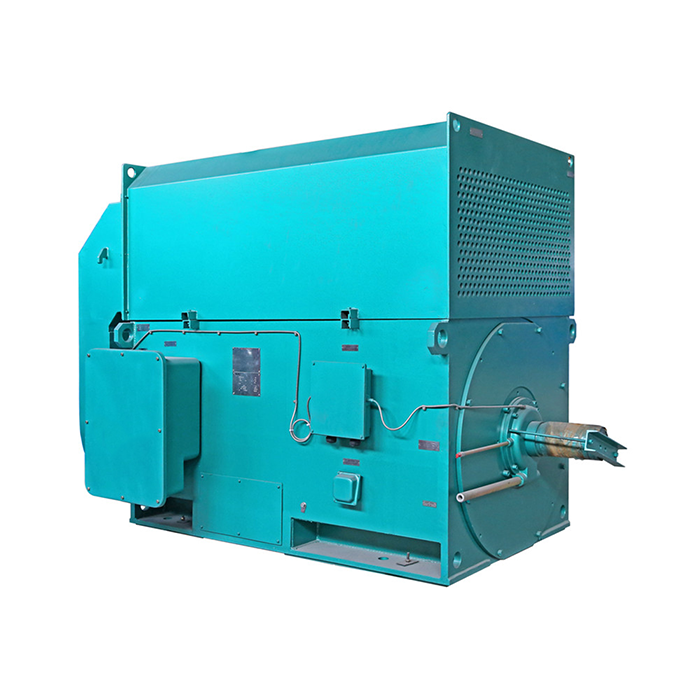

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding 4000 kW Motors: Specifications and Working Principles

High-power industrial motors efficiently transform electrical energy into mechanical power. These electromagnetic motors create rotational force using meticulously engineered stator windings and precision-balanced rotor assemblies.

Essential Technical Details

Industrial motors' technological base includes several essential characteristics that define their application acceptability. Power output is the highest mechanical energy these motors can deliver continuously. Modern high-capacity motors run from 3000V to 11000V, accommodating various industrial power distribution systems while maintaining operational flexibility. Motor speed depends on frequency, with most industrial applications using 50Hz power supplies. Pole configuration and application requirements determine speed ranges, usually 500 to 3000 RPM. Protection standards like IP54 protect internal components from environmental pollutants, while insulation class ratings like F or H grade assure dependable operation at high temperatures.

Upgraded Design

Modern industrial motor frames are made of cast iron for durability under harsh conditions. Precision-balanced rotor assemblies reduce vibration and maximise smooth performance, extending mechanical component life. High-quality bearing systems, including SKF, NSK, and FAG choices, save maintenance and assure reliable rotation. Even during heavy loads, advanced cooling technologies maintain appropriate temperatures. These advanced thermal management technologies avoid overheating and maintain performance in different environments. Real-time thermal monitoring by PT100 temperature sensors in stator windings and bearing assemblies enables predictive maintenance to reduce unexpected downtime.

Applications and Advantages of 4000 kW Motors in Heavy Industry

Heavy industrial applications require motor solutions that can handle heavy mechanical loads and work consistently over time. These powerful electric machines are used in many industries, each with its own operational issues and performance needs.

Main industrial uses

Automotive, aerospace, and electronics factories use high-capacity motors to power manufacturing equipment. Motors with high torque and power, such as 4000 kw motor, are needed for large compressors, industrial fans, and processing machinery. Crusher systems, conveyor belts, and extraction equipment in mining operations require reliability under difficult conditions. Powerful motors power pumps, aerators, and filtration systems that process millions of gallons daily in water treatment facilities. Auxiliary, cooling, and fuel handling equipment in power plants use these motors. Steel and cement factories need high-quality electricity for rolling mills, kilns, and material handling equipment.

Benefits of operation

Modern industrial motors excel at energy efficiency, reaching 95% under ideal conditions. The result is lower operational expenses and better environmental performance. The low noise operation, usually under 85 dB(A), allows installation in facilities with rigorous acoustic standards and reduces worker exposure to noise. Low vibration protects connected equipment and reduces mounting system stress. With adequate maintenance, industrial facilities can last 20 years or more and have a high ROI. Installation and maintenance are simple, reducing commissioning and service downtime.

Comparing Top 4000 kW Motor Brands and Models

Several industrial motor manufacturers have considerable industry experience. Understanding motor technologies and design techniques helps procurement experts make operationally relevant selections.

Variations in Motor Technology

Strong construction and reliable performance make induction motor technology the standard in heavy industrial applications. These motors create rotational force without stator-rotor connections using electromagnetic induction. This design reduces wear and improves reliability under extreme situations. Facilities seek energy savings and process control, making variable frequency drive compatibility crucial. Modern motors have improved insulation and bearing protection to manage VFD electrical stresses. Compatibility allows fine speed control and lowers energy usage under partial load.

Considerations for Performance and Value

Investment costs must be balanced against operational costs and reliability when making procurement selections. High-efficiency designs cost more but save energy over time. Service assistance and technical competence from manufacturers affect total cost of ownership, especially for complex installations or specialised applications. Quality certifications and international standards guarantee performance and safety. JB/T 12730 and 12729 compliance assures motors pass stringent industrial testing. Extended warranty coverage and service support networks decrease maintenance risks and improve uptime guarantees.

How to Choose and Procure the Best 4000 kW Motor: A Decision Support Guide

Successful motor procurement demands thorough examination of technical, operational, and long-term support needs. This organised technique selects motors that meet application needs and provide optimal value throughout their lives.

Technical Requirements Definition

Motor selection depends on load parameters such as starting torque, operational speed, and duty cycle. Environmental variables like ambient temperature, humidity, and contaminant exposure affect motor design and protection ratings for reliable operation. For high-demand applications, a 4000 kw motor may be necessary to meet performance needs. Motor performance and longevity depend on power supply voltage, frequency stability, and harmonic content. Consider integration requirements with current control systems, variable frequency drives, and automation equipment to assure system operation. Sizing considerations should consider future expansion and load increases to minimize premature replacement.

Supplier Evaluation Criteria

Product reliability and support quality are shown by manufacturer reputation and industry experience. Technical competence in specific applications guides motor selection and application. Service network coverage and response affect motor maintenance costs and downtime hazards throughout its life. Quality systems and certifications show manufacturing commitment to product quality and performance. Delivery and logistical support are crucial for time-sensitive projects or remote installations. Technical documents, spare parts, and training facilitate long-term operation.

Installation, Operation, and Maintenance: Ensuring Optimal Performance

Reliable motor operation starts with proper installation. Commissioning according to manufacturer and industry standards reduces failures and optimises performance.

Installation Best Practices

Alignment tolerances and vibration isolation must be considered during foundation preparation. Driving equipment requires precise alignment and enough support from mounting surfaces. Electrical connections require adequate cable sizing, termination, and protection for safe, reliable operation. Maintaining optimal operating temperatures requires cooling system installation with suitable ventilation clearances and air flow patterns. Bearing requirements and operating circumstances determine grease kinds and volumes for lubrication systems. All protection systems are tested and loaded gradually to rated capacity during startup.

Preventative Maintenance

Regular inspections include visual, thermal, and vibration analysis to find flaws before they fail. Lubrication and replacement of bearings depend on operating hours and environment. Insulation testing, connection tightening, and protective device verification are electrical system maintenance. Performance monitoring through continuous data gathering allows predictive maintenance to optimise replacement scheduling and save downtime. Documenting maintenance and performance trends helps warranty compliance and informs buying decisions.

Company Introduction and Our 4000 kW Motor Solutions

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides high-efficiency, low-energy motor systems with dependable power delivery as a power equipment solutions supplier. We understand the particular issues procurement managers and technical teams face across varied industrial sectors due to our strong industrial application experience.

Top Manufacturing Skills

Our motor manufacturing process uses precision die-casting, sophisticated winding, and vacuum pressure impregnation for excellent insulation. Dynamic rotor assembly balancing prevents vibration, and rigorous testing processes ensure performance before shipment. Production-wide quality control ensures motor unit performance and reliability. 3.3kV to 11kV voltage flexibility facilitates industrial power distribution systems, while 200-3150 kW power meets application needs. For high-power applications, a 4000 kw motor is available to meet the most demanding requirements. IP54 protection ratings provide reliable performance in harsh industrial environments, while innovative cooling systems maintain appropriate temperatures under severe load.

Complete Service Support

Beyond product delivery, we offer technical assistance and consultancy. Throughout the motor's life, experienced engineers give application guidance, installation support, and troubleshooting. Original replacement parts from trusted sources and 30-day return procedures give procurement confidence. Fast delivery reduces project delays, while 24/7 customer support answers technical concerns and provides service. We develop long-term collaborations with industrial clients because we know how important reliable motor systems are for productivity.

Conclusion

Technical specifications, operating requirements, and long-term support must be considered when choosing high-power motors for heavy industrial applications. Advanced engineering, dependability, and service support enable project success and reduce operational risks. Modern motor technology reduces maintenance and operational expenses while improving efficiency and performance. Partnering with skilled vendors delivers technical expertise and support services that maximise motor ROI throughout its lifespan.

FAQ

1. What factors affect industrial motor efficiency?

Power quality, load parameters, and operating circumstances affect motor efficiency. Motors sized properly and working at 75-100% of rated load are most efficient. Power supply voltage stability and harmonic content affect efficiency, while clean power sources improve performance. Proper lubrication and alignment maintain efficiency over time.

2. How long do heavy-use industrial motors last?

With proper maintenance, continuous duty industrial motors last 15-25 years. Operating variables including temperature, pollution, and load affect longevity. Maintenance programs including bearing replacement, insulation testing, and cooling system cleaning extend life and performance.

3. What are typical large motor order lead times?

Standard industrial motor deliveries take 8-16 weeks, depending on specs and quantity. Specialised configurations or features may delay delivery by 12-20 weeks. Priority scheduling and quality control are common for bulk orders. Open communication with suppliers before order placing helps set reasonable delivery expectations.

Contact XCMOTOR for Your 4000 kW Motor Requirements

XCMOTOR offers complete 4000 kw motor solutions for heavy industry. Our experts combine technical expertise with practical application knowledge to offer optimal motor configurations for your operations. We provide reliable products and thorough service for single or bulk orders. Connect with our technical specialists today by contacting xcmotors@163.com for detailed product information and personalized recommendations. We offer low pricing, rapid delivery, and technical assistance to assure project success as a trusted 4000 kw motor supplier. We are the preferred industrial motor solution provider for numerous applications due to our quality and customer satisfaction.

References

1. Industrial Motor Selection and Application Guidelines for Heavy Industry," IEEE Industry Applications Society, 2023.

2. Energy Efficiency Standards for Large Industrial Motors," International Electrotechnical Commission, 2022.

3. Predictive Maintenance Strategies for High-Power Electric Motors," Machinery Maintenance and Reliability Journal, 2023.

4. Heavy Industry Motor Applications: Performance and Reliability Analysis," Industrial Power Systems Conference Proceedings, 2022.

5. Procurement Best Practices for Industrial Electric Motors," B2B Industrial Equipment Review, 2023.

6. Motor Protection and Safety Standards in Industrial Applications," National Electrical Manufacturers Association, 2022.