Using a vfd duty motor safely requires proper understanding of installation procedures, operational protocols, and maintenance practices. Variable frequency drives paired with specially designed motors deliver exceptional speed control and energy efficiency across industrial applications. This comprehensive guide walks you through essential safety steps, from initial setup through daily operations, ensuring your equipment performs reliably while protecting personnel and machinery. Whether you're managing manufacturing processes, HVAC systems, or industrial automation, following these proven safety protocols maximizes performance while minimizing risks associated with motor drive systems.

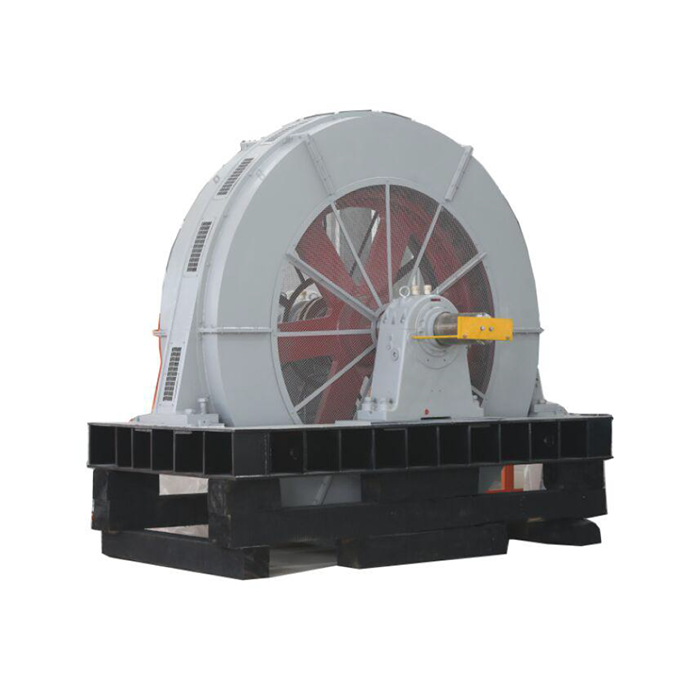

Series:YVFE5

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding VFD Duty Motor Fundamentals

VFD duty motors represent specialized AC motors engineered to withstand the unique electrical stresses created by variable frequency drives. Unlike standard induction motors, these units feature enhanced insulation systems that resist voltage spikes and harmonics generated by frequency converters.

The inverter technology in modern adjustable speed drives creates rapid voltage transitions that can stress conventional motor windings. VFD-rated motors incorporate Class F or Class H insulation materials that maintain integrity under these challenging conditions. This enhanced protection ensures reliable operation across varying frequencies and speeds.

Industrial automation systems benefit significantly from the precise speed control these motors provide. Manufacturing facilities in automotive, aerospace, and electronics industries rely on consistent motor performance for critical processes. The combination of variable frequency drives with properly rated motors delivers the torque characteristics needed for demanding applications.

Motor efficiency improves substantially when VFD technology matches load requirements. Energy consumption drops as the drive adjusts motor speed to actual demand rather than running at constant speed with mechanical throttling. This optimization proves particularly valuable in HVAC applications where load variations occur frequently throughout operating cycles.

Pre-Installation Safety Assessment

Conducting thorough safety assessments before installation prevents costly mistakes and potential hazards. Environmental conditions significantly impact motor performance and longevity, making proper evaluation essential for successful deployment.

- Electrical supply quality requires careful examination to ensure compatibility with both the motor and frequency converter. Voltage imbalances, harmonic distortion, and power factor issues can compromise system performance. Professional electrical analysis identifies potential problems before they affect equipment operation.

- Mechanical mounting considerations include vibration analysis, alignment requirements, and thermal expansion allowances. Synchronous motor applications demand precise alignment to prevent premature bearing failure and excessive noise. Proper foundation design distributes mechanical loads evenly while accommodating thermal growth.

- Ambient temperature and humidity levels affect insulation life and overall motor reliability. Ventilation requirements vary based on enclosure type and heat dissipation needs. Adequate airflow prevents excessive temperature rise that could damage windings or reduce bearing life.

- Electrical clearances must meet local codes and manufacturer specifications. Arc flash analysis determines appropriate personal protective equipment requirements for maintenance personnel. Proper grounding systems protect both equipment and personnel from electrical faults.

Safe Installation Procedures

- Professional installation begins with verifying that all components match system specifications. VFD duty motor nameplate data must align with drive output capabilities to prevent damage from overcurrent or overvoltage conditions.

- Power isolation remains critical throughout the installation process. Lockout/tagout procedures ensure electrical safety while personnel work on connections. Multiple energy sources may require isolation, including control circuits and auxiliary power supplies.

- Cable selection influences system performance and safety significantly. VFD applications require cables designed for inverter duty service. These specialized conductors resist the high-frequency voltage stresses created by pulse-width modulation switching. Proper cable routing minimizes electromagnetic interference that could affect nearby control systems.

- Grounding practices deserve special attention in motor drive installations. Multiple grounding points can create current loops that cause bearing damage through electrical discharge machining. Single-point grounding schemes eliminate these destructive currents while maintaining electrical safety.

- Motor protection devices integrate with the drive system to provide comprehensive fault detection. Current monitoring, thermal protection, and ground fault detection work together to prevent damage from abnormal operating conditions. Proper calibration ensures protection activates before damage occurs while avoiding nuisance trips.

Operational Safety Protocols

Daily operations require consistent adherence to established safety procedures.

- Startup sequences should follow manufacturer recommendations to prevent mechanical shock and electrical stress. Gradual acceleration protects connected equipment from sudden torque changes.

- Monitoring systems provide real-time feedback on motor performance and condition. Temperature sensors, vibration detectors, and current analyzers alert operators to developing problems before failures occur. Regular data review identifies trends that indicate maintenance needs or operational adjustments.

- Speed changes must occur within motor design limits to prevent overheating or mechanical stress. Extended operation at low speeds may require auxiliary cooling to maintain proper thermal balance. The relationship between motor speed and cooling fan effectiveness affects thermal capability significantly.

- Emergency stop systems require regular testing to ensure proper function. These safety devices must halt motor rotation quickly while protecting personnel and equipment. Response times and stopping distances should meet applicable safety standards for the specific application.

- Load monitoring prevents motor overload conditions that could cause insulation damage. Current measurement provides immediate feedback on loading conditions. Trending analysis reveals gradual load increases that might indicate mechanical problems in driven equipment.

Maintenance and Inspection Guidelines

Preventive maintenance programs extend VFD duty motor life while ensuring safe operation. Regular inspections identify developing problems before they create safety hazards or equipment damage. Maintenance intervals depend on operating conditions and application severity.

- Insulation resistance testing reveals deterioration in motor windings before failures occur. Megohm readings should remain above manufacturer specifications across all operating temperatures. Trending these measurements over time provides early warning of insulation degradation.

- Bearing maintenance requires attention to lubrication quality and quantity. VFD applications may create bearing currents that accelerate wear if proper grounding practices aren't followed. Vibration analysis detects bearing problems before catastrophic failure occurs.

- Thermal imaging identifies hot spots that indicate problems with connections, windings, or cooling systems. Regular thermal surveys document normal operating temperatures and reveal developing issues. Temperature rise patterns help diagnose specific problems affecting motor performance.

- Connection torque verification prevents loose terminals that could create arcing or overheating. Thermal cycling from normal operation can loosen electrical connections over time. Periodic retorquing according to manufacturer specifications maintains reliable electrical contact.

Troubleshooting Common Issues

Effective troubleshooting requires systematic approaches that prioritize safety while identifying root causes. Many motor problems result from installation issues or operating condition changes rather than component failures.

- Excessive motor heating often indicates problems with ventilation, loading, or electrical supply quality. Voltage imbalances create negative sequence currents that generate additional heat in motor windings. Power quality analysis helps identify electrical causes of thermal problems.

- Unusual noise or vibration may signal mechanical misalignment, bearing wear, or electrical issues. Frequency analysis helps distinguish between different sources of mechanical problems. Electrical noise patterns often correlate with specific drive operating conditions or parameter settings.

- Frequent drive trips could indicate motor problems, application issues, or environmental factors. Fault history analysis reveals patterns that help identify systematic problems. Parameter adjustments may resolve issues related to acceleration rates, current limits, or protection settings.

- Performance degradation over time suggests wear or environmental effects on motor components. Efficiency measurements help quantify performance changes and guide maintenance decisions. Baseline data from commissioning provides reference points for condition assessment.

Conclusion

Safe operation of VFD duty motors requires comprehensive understanding of installation procedures, operational protocols, and maintenance practices. Following established safety guidelines protects personnel while maximizing equipment reliability and performance. Regular monitoring and preventive maintenance identify potential issues before they create safety hazards or operational disruptions. Professional installation and quality components form the foundation for successful motor drive applications across industrial automation, HVAC, and process control systems. Partnering with experienced suppliers ensures access to technical expertise and reliable products essential for demanding applications.

Partner with XCMOTOR for Reliable VFD Motor Solutions

Selecting the right vfd duty motor supplier ensures access to quality products and technical expertise essential for safe operations. XCMOTOR delivers comprehensive power equipment solutions backed by proven reliability and dedicated support services.

Our extensive product portfolio includes VFD-rated motors engineered for demanding industrial applications. Each motor undergoes rigorous testing to verify performance under variable frequency drive conditions. Quality components from trusted brands ensure consistent operation across diverse environments.

Technical support extends beyond product delivery to include application guidance and troubleshooting assistance. Our engineering team understands the complexities of motor drive systems across manufacturing, HVAC, and process control applications. This expertise helps customers optimize system performance while maintaining safety standards.

Fast delivery capabilities minimize downtime when replacement motors are needed. Our inventory management ensures availability of common motor configurations while custom solutions address unique application requirements. Emergency support services provide weekend and holiday assistance when critical operations depend on motor performance.

Comprehensive warranty coverage protects your investment while demonstrating confidence in product quality. Our 30-day return policy allows thorough evaluation of motor performance in actual operating conditions. When you need a reliable vfd duty motor manufacturer committed to customer success, contact us at xcmotors@163.com for expert guidance and competitive solutions.