When choosing the correct YBX5 explosion-proof motor, you need to think about a lot of things, such as how much power it needs, what the environment is like, and what safety certifications it has. The YBX5 series has power ranges from 0.55kW to 630kW, different voltage choices, and ATEX-compliant enclosures that keep explosive atmospheres from catching fire. These features make the YBX5 series very safe for dangerous locations. This detailed selection guide looks at technical parameters, application demands, and installation factors to assist engineers choose the best options for their unique industrial needs.

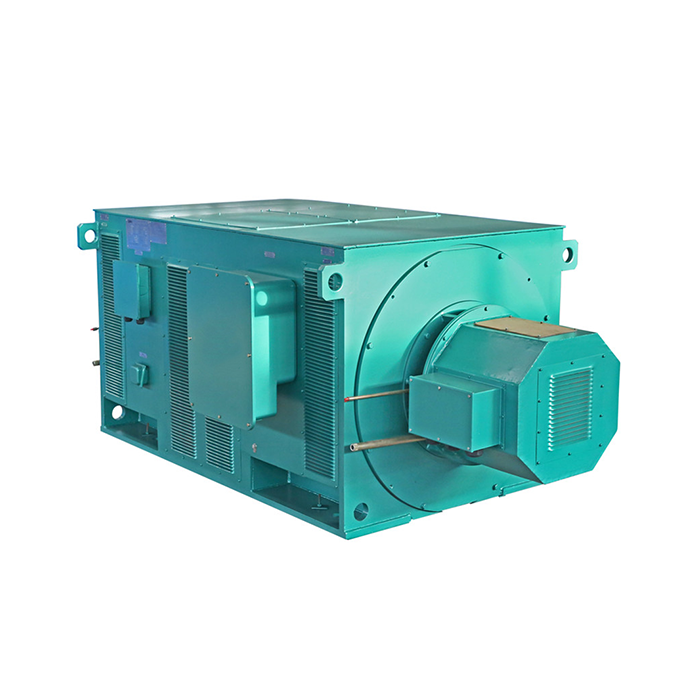

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

How to Understand Explosion-Proof Motor Technology

Explosion-proof motors work in a way that is quite different from how regular industrial motors work. These specialized machines keep any internal explosions contained inside their strong enclosures, which keeps dangerous atmospheres outside from catching fire. The flameproof construction makes sure that hot gasses can't get out at temperatures that may start fires in nearby flammable objects.

The YBX5 explosion-proof motor has a squirrel cage design and is totally enclosed. This setup prevents sparks from happening outside while yet allowing heat to escape quickly using self-fan cooling devices. The motor enclosure can handle sudden changes in internal pressure and stays strong even when the motor is running at its most severe settings.

Advanced winding insulation prevents moisture and chemicals from getting in. The Class F insulation grade can manage temperatures up to 155°C, which gives it a lot of room to work continuously. The IP55 protection level, on the other hand, keeps dust and water from getting in, which might hurt performance.

Modern explosion prevention goes beyond just keeping things inside. Thermal protection systems keep an eye on the temperatures at which things are running, while vibration monitoring systems find problems with bearings or alignment before they cause breakdowns. These built-in safety measures cut down on maintenance needs and let the equipment last longer in tough industrial settings.

Key Specifications and Technical Parameters

The YBX5 explosion-proof motor can handle a range of voltage needs, including configurations like 380V, 660V, 415V, 380/660V, and 660/1140V. This flexibility makes it possible to add it to current electrical systems without having to make expensive changes to the infrastructure. The power output ranges from 0.55 kW for modest process applications to 630 kW for massive industrial machines.

The speeds vary from 750 to 3000 rpm, which is enough for most industrial drives. High-torque applications like crushers and mills work well at lower speeds, whereas pumps and fans work best at higher speeds. The IE5 efficiency categorization makes sure that energy is not wasted, which lowers operating expenses over long durations of service.

Different system needs may be satisfied by different starting techniques. For smaller motors, direct-on-line starting is easier, while for bigger motors, star-delta designs lower inrush currents. Soft start features keep mechanical systems safe from torque spikes as they speed up.

Environmental specs say that the device can work at temperatures between -20°C and +40°C and at heights of up to 1000 meters. These requirements apply to most industrial locations across the globe. However, sophisticated cooling systems may make them work under even harsher conditions. The strong cast iron structure makes it very strong mechanically and helps it lose heat.

Criteria for Choosing Applications

Different industries have their own problems that need particular motor specs. Petrochemical plants need chemicals that are very resistant to heat and chemicals. The design of the motor shaft seal prevents hydrocarbons from getting in while yet allowing the motor to spin efficiently. Certain types of bearings are resistant to chemical attacks from industrial gasses and vapors.

Mining exposes equipment to rough dust and mechanical trauma. These tough circumstances may be handled via thicker enclosures and stronger mounting options. Electrical connections that don't vibrate stay tight even while they're under continual mechanical stress, and sealed terminal boxes keep out moisture and particles.

Food processing areas need to be able to be washed down and not rust. Stainless steel hardware and unique coatings keep cleaning chemicals and moisture from getting in. Smooth surface finishes stop germs from building up and make it easier to clean.

Reliability and efficiency are very important to power producing plants. Continuous duty ratings make sure that things run well even when there is a lot of demand. Advanced bearing systems can handle temperature cycling caused by changes in load, and extra protective circuits prevent electrical problems from damaging the system.

HVAC systems need to be able to run quietly and at different speeds. Balanced rotor assemblies reduce the amount of vibration that gets to building structures. Optimized cooling systems keep performance steady across a broad range of speeds without lowering motor efficiency.

Standards for safety certifications and compliance

ATEX certification proves that motors work well in European markets where there is a chance of an explosion. The Ex d I Mb rating is for mining applications where methane is present. The Ex d IIB T4 Gb and Ex d IIC T4 Gb ratings are for industrial gas situations where the danger of igniting is different.

International acceptance for explosion prevention measures comes from IECEx standards. These certifications make it easier for equipment to be approved in many nations, which cuts down on project delays and compliance expenses. Regular recertification makes ensuring that safety standards are still being met as they change.

Temperature categorization systems show the highest surface temperatures that may be reached under different operating situations. For most industrial uses, the T4 classification restricts surface temperatures to 135°C. Engineers can choose the right motors for certain hazardous area categories by knowing these restrictions.

Intrinsic safety designs work well with explosion-proof enclosures by restricting the energy that may start a fire. These concepts don't apply to building motors, but they do affect how control systems are put together and how sensors are chosen to safeguard all areas of danger.

Things to think about while installing and maintaining

Proper installation has a big effect on how long a motor lasts and how safe it is. Designs for foundations must be able to handle changing loads and stop vibrations from spreading. Alignment processes make sure that the load is evenly spread out across the bearing surfaces, which avoids early wear and possible failure modes.

For hazardous area installations, electrical connections need unique methods. Cable glands keep their explosion-proof integrity while still allowing for thermal expansion. Following the right termination steps avoids hot spots that might damage insulation or start fires.

Maintaining the cooling system keeps its thermal performance high for its entire service life. Cleaning the fan blades gets rid of dirt and other things that block airflow. To keep heat transfer working well, heat exchanger surfaces need to be checked on a regular basis, especially in dusty places.

The plan for bearing maintenance changes depending on how the machine is used and how much weight it can handle. If you take care of the lubrication properly, premium bearing brands like SKF, NSK, and FAG will last longer. Condition monitoring systems find issues before they become bad enough to cause big failures.

The design of an electrical system is affected by the characteristics of the motor's starter current. Soft starting puts less strain on power distribution systems and makes motors last longer. Knowing these parameters while choosing protective devices keeps them from being too big and makes the system more reliable.

Things to think about for improving performance and efficiency

The efficiency of the motor has a direct effect on the cost of running it over long periods of time. IE5 efficiency ratings show the best performance levels attainable, which means less energy use and heat production. These benefits are especially important when the device is used all the time.

Load matching improves both the power factor and the efficiency. When motors are run close to their rated capacity, they work best and use the least amount of reactive power. Variable frequency drives may help with part-load performance when process needs change a lot.

Thermal management is more than just keeping things cool. Knowing where heat comes from and how it moves helps you make the best installation plans. A well-designed ventilation system keeps the air temperature at a comfortable level and prevents contaminants from getting in.

The quality of the power affects how well a motor works and how long it lasts. When voltage is unbalanced, it causes negative sequence currents that waste energy and lower efficiency. Variable speed drives may cause harmonic distortion that has to be filtered to prevent insulation stress and bearing currents from happening.

Conclusion

Selecting the optimal YBX5 explosion-proof motor requires careful evaluation of technical specifications, environmental conditions, and safety requirements. Understanding power ranges, voltage options, and efficiency classifications helps engineers match motor capabilities to application demands. Proper installation, maintenance, and performance optimization ensure reliable operation throughout extended service periods. XCMOTOR's comprehensive product line and technical expertise provide the foundation for successful hazardous area motor applications across diverse industrial sectors.

Why Choose XCMOTOR for Your YBX5 Explosion-Proof Motor Requirements

XCMOTOR stands as a trusted ybx5 explosion-proof motor manufacturer, combining decades of engineering expertise with cutting-edge manufacturing capabilities. Our comprehensive product line serves diverse industrial applications from petrochemical processing to renewable energy generation. Each motor undergoes rigorous testing protocols ensuring reliable performance in the most demanding environments. As your dedicated ybx5 explosion-proof motor supplier, we understand the critical importance of equipment reliability in hazardous area applications. Our engineering team provides detailed technical support throughout the selection process, ensuring optimal motor specifications for your specific requirements. Premium bearing options from trusted manufacturers accommodate varying service intervals and maintenance preferences.

XCMOTOR's commitment to quality extends beyond initial delivery. Our comprehensive warranty coverage and dedicated technical support ensure maximum uptime for your critical operations. Fast delivery capabilities minimize project delays, while our 30-day return policy provides confidence in product selection decisions.

Contact our technical specialists today to discuss your explosion-proof motor requirements. Our experienced engineers will help you navigate the selection process, ensuring optimal performance and compliance for your specific application. Reach out to us at xcmotors@163.com to discover how XCMOTOR can enhance your industrial operations with reliable, efficient explosion-proof motor solutions.