Best 1440 RPM Motors for Long-Lasting Performance in 2026

If you want the most reliable motor options in 2026, 1440 RPM motors are the best choice for commercial uses that need reliable performance and long life. These motors have the best speed qualities for challenging applications in the energy, HVAC systems, and industrial sectors. With their mix of tried-and-true engineering principles and cutting-edge materials, 1440 RPM motors are great investments for businesses that need stable power solutions that will last for a long time.

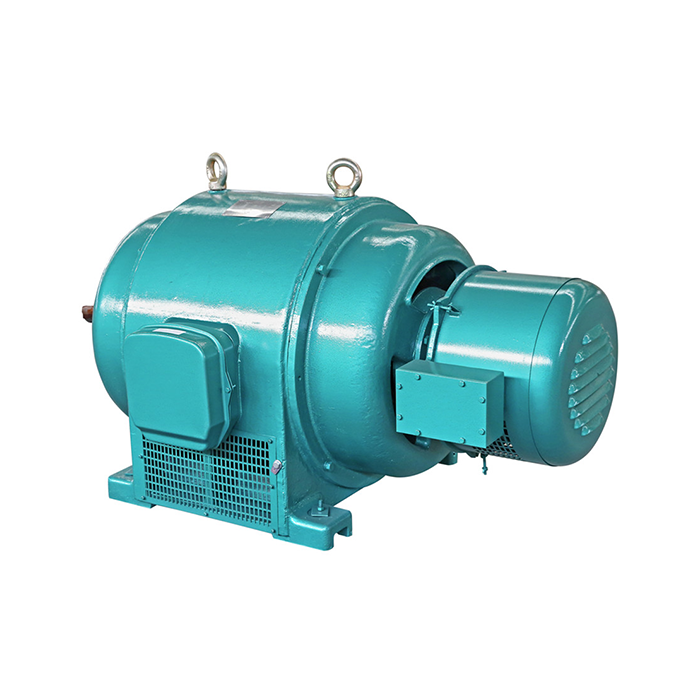

Series:YE4

Frame number: 80-450

Power range:0.75-1000kW

Protection level:IP55

Energy efficiency class: IE4

Voltage range: 380V,400V,415V, 660V,etc.

Application:can be used in various fields of the national economy, such as machine tools,water pumps,fans,compressors,and can also be used in transportation, mixing, printing, agricultural machinery, food and other occasions that do not contain flammable, explosive or corrosive gases.

Certificate: international standard IEC60034-30 ""Efficiency Classification of Single-speed Three-Phase Squirrel Cage Induction Motors"".

Advantage:The high quality of the electric motor guarantees high operational reliability.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Introduction

1440 RPM motors offer a balanced combination of speed, torque, and energy efficiency, making them ideal for industries like manufacturing, HVAC, and process control. Their reliable performance under varying loads and energy-efficient designs reduce operational costs and maintenance, boosting reliability and productivity across sectors like automotive and aerospace.

Why Focus on 1440 RPM Motors for Industrial Applications

- The 1440 RPM motor category deserves special attention because these units address critical operational requirements across multiple industrial sectors. Unlike higher-speed alternatives, these motors provide controlled rotational speeds that work perfectly with pumps, compressors, and conveyor systems without requiring complex speed reduction mechanisms.

- Manufacturing environments benefit tremendously from the inherent stability that 1440 RPM motors provide. The moderate speed range allows for precise control over production processes while maintaining the high torque characteristics needed for heavy-duty applications. This combination proves particularly valuable in automated systems where consistent performance directly affects product quality.

- Process control applications rely heavily on the predictable characteristics of 1440 RPM motors. These motors integrate seamlessly with variable speed drives, allowing operators to fine-tune performance based on real-time operational requirements. The brushless motor designs commonly found in this category require minimal maintenance, reducing operational disruptions.

- Energy efficient operation becomes increasingly important as utility costs continue rising globally. Modern 1440 RPM motors achieve IE4 efficiency ratings, significantly reducing power consumption compared to older motor technologies. This efficiency improvement translates directly into cost savings that compound over the motor's operational lifetime.

Selection Criteria for the Best 1440 RPM Motors

Identifying superior 1440 RPM motor solutions requires evaluating multiple performance factors that directly impact long-term operational success. Power range flexibility ensures that single motor families can address diverse application requirements, reducing inventory complexity while maintaining performance standards.

- Efficiency ratings serve as primary indicators of motor quality and operational cost-effectiveness. IE4-rated motors represent current technology standards, providing maximum energy efficient operation while meeting international regulatory requirements. These ratings directly correlate with reduced operational expenses and environmental impact.

- Protection levels determine motor suitability for specific operating environments. IP55 protection ensures reliable operation in dusty or moisture-prone conditions common in manufacturing facilities. This protection level extends motor lifespan significantly by preventing contamination of internal components.

- Voltage compatibility affects installation flexibility and global market applicability. Motors supporting multiple voltage configurations (380V, 400V, 415V, 660V) accommodate diverse electrical systems without requiring additional transformation equipment. This flexibility reduces installation complexity and costs.

- Bearing quality directly impacts maintenance requirements and operational reliability. Premium bearing options from established manufacturers ensure extended operational periods between maintenance intervals. The ability to specify bearing brands based on application requirements provides additional customization options.

- Certification compliance ensures motors meet international safety and performance standards. IEC60034-30 certification guarantees efficiency claims while providing assurance of quality manufacturing processes. These certifications become essential when supplying equipment to regulated industries.

Top 1440 RPM Motor Solutions for 2026

YE4 Series High-Efficiency Industrial Motors

The YE4 series represents advanced engineering in the 1440 RPM motor category, delivering exceptional performance across power ranges from 0.75kW to 1000kW. These motors achieve IE4 efficiency ratings through optimized electromagnetic designs and premium materials that maximize energy conversion while minimizing losses.

The cast iron frame design better removes heat than metal options, making sure stable operation during continuous job cycles. The strong design successfully handles shaking and heat stress, greatly increasing the operating lifetime. This long-lasting design method cuts down on the number of replacements needed and the costs that come with them.

Copper wires are better at conducting electricity than regular metal wires, which makes the device use less energy and produce less heat. Precision wrapping methods are used to make sure that the magnetic field is always the same. This makes the power delivery smooth across the whole speed range. In precision control uses, this uniformity is very important.

Good shielding materials keep internal parts safe from electrical stress and external contamination. The Class F insulation values (155°C) offer large thermal buffers, ensuring stable operation even in industrial settings where temperatures are often high. This heat safety makes the motor last a lot longer.

Bearing systems that are technologically advanced and make use of deep groove ball bearings guarantee a smooth operation with low vibration. Because the bearing selection is able to successfully support both radial and axial stresses, these motors are suited for a variety of mounting orientations. Various premium bearing brands are available as an option to meet the needs of certain applications.

Having a protection certification of IP55 guarantees dependable performance in demanding industrial situations where dust and moisture are persistent issues. In addition to ensuring that there is sufficient air for cooling, the structure allows for the prevention of contamination. The vast majority of industrial and process control applications are ideally suited to this degree of security.

Different electricity systems can use the 380V, 400V, 415V, and 660V power settings without any changes. This freedom makes buying things easier and lowers the amount of goods that international businesses need. The wide voltage range makes sure that it works with power standards around the world.

Premium Efficiency Automation Motors

For robotics and material handling, specialized 1440 RPM motors for automation provide accurate speed control, low noise operation, and strong starting torque. These characteristics are required for effective operation. When combined with thermal protection and seamless interaction with automation networks, their small design makes them suitable for space-constrained systems. Additionally, their design enables predictive maintenance, which improves the overall reliability and performance of the system.

Heavy-Duty Process Control Motors

The 1440 RPM motors used in industrial operations are resistant to corrosion, have better cooling systems, and have precision-balanced rotors to reduce vibration. These motors are intended to operate in tough environments. Compatibility with motor drivers provides smooth integration with contemporary control systems, which results in maximum efficiency and dependability. Flexible installation and increased bearing life decrease the amount of maintenance being performed.

Global Market Analysis and Regulatory Considerations

Regional restrictions and tastes are the primary factors that define the worldwide market for 1440 RPM motors. While North America offers incentives to premium motors, Europe is concentrating on IE4 efficiency requirements, while Asia is demanding solutions that are compatible with automation. Whereas environmental rules are pushing for designs that are energy efficient, emerging markets place a higher priority on durability. Also affecting motor availability and prices across areas are issues related to the supply chain.

XCMOTOR's Advanced 1440 RPM Motor Solutions

XCMOTOR offers reliable 1440 RPM motors ranging from 0.75kW to 1000kW with IE4 efficiency, reducing costs and supporting sustainability. We supply high-quality, original components for critical industrial applications.

Purchasing Recommendations and Key Considerations

Evaluate the requirements of the application, the circumstances of the environment, and the efficiency of the motor before selecting the appropriate 1440 RPM motor. The majority of businesses may benefit from the protection provided by IP55, while IE4-rated motors provide long-term savings on energy use. When it comes to lowering costs and guaranteeing dependable operation, the simplicity of maintenance, the availability of replacement parts, and integration with control systems are all essential components.

Industry Trends and Technology Outlook

In the 1440 RPM motor business, things are always changing to make them more efficient and smarter so they can meet the needs of modern industrial technology. When IoT systems are integrated, predictive maintenance methods can be used to reduce unplanned downtime and make the best use of maintenance plans. Cutting-edge materials and manufacturing methods increase power output while lowering the size and weight of the motor. More and more complex variable speed drive integration makes it possible to precisely control processes that raise the quality of products and lower waste. Because of these improvements in technology, 1440 RPM motors will continue to be important parts of current industry processes.

Conclusion

For business uses that need solid performance and energy-efficient operation, the 1440 RPM motor group has great options. These are good motors that have the right amount of speed, power, and controllability for current industrial and process control needs. When you invest in high-efficiency motors, you lower your running costs by a lot and help the environment at the same time. The best performance and highest return on investment are guaranteed for industrial activities in a wide range of fields by careful selection based on application needs.

Frequently Asked Questions

1. What applications benefit most from 1440 RPM motors?

1440 RPM motors excel in pump applications, conveyor systems, compressors, and fans where moderate speeds provide optimal efficiency. The speed characteristics match well with centrifugal loads common in HVAC systems and process control applications. Manufacturing equipment benefits from the stable torque delivery and precise control capabilities these motors provide.

2. How do IE4 efficiency ratings impact operational costs?

IE4-rated 1440 RPM motors consume approximately 15-20% less energy compared to IE2-rated alternatives. This reduction translates to substantial cost savings over the motor's operational lifetime. Typical payback periods range from 6-18 months depending on operational hours and local energy costs.

3. What maintenance requirements do modern 1440 RPM motors have?

Quality 1440 RPM motors with premium bearings typically require bearing lubrication every 8,000-10,000 operating hours. Regular inspection of mounting bolts, electrical connections, and ventilation systems ensures optimal performance. Thermal monitoring helps identify potential issues before failures occur.

4. Can these motors operate with variable frequency drives?

Most modern 1440 RPM motors integrate seamlessly with variable frequency drives, enabling precise speed control and energy optimization. The combination provides excellent starting characteristics and allows speed adjustment based on load requirements. Drive compatibility should be verified during motor selection.

5. What protection levels are recommended for different environments?

Standard industrial applications typically require IP55 protection for adequate dust and moisture resistance. Food processing and chemical applications may need IP56 or higher ratings. Outdoor installations often specify weatherproof enclosures that exceed standard IP ratings.

6. How do bearing options affect motor performance and maintenance?

Premium bearing options extend maintenance intervals significantly while reducing vibration and noise levels. Standard bearings suit most applications effectively, while specialized environments may benefit from ceramic or sealed bearing alternatives. Bearing selection affects both initial cost and long-term maintenance requirements.

Boost Your Efficiency with Our 1440 RPM Motors!

At XCMOTOR, we are committed to providing top-tier power equipment solutions that combine high energy efficiency, low energy consumption, and dependable performance. Our 1440 RPM motors are designed to meet the highest standards of reliability and efficiency for sale, making them perfect for a wide range of industrial applications, including pumps, compressors, and machine tools. With a robust cast iron frame, copper windings, and premium quality insulation, these motors are built to withstand demanding environments and deliver consistent results.

Why choose us? We offer fast delivery, free shipping, a 30-day return policy, and dedicated weekend support. Our motors come with the latest IE4 energy efficiency class and meet international IEC60034-30 standards, ensuring they exceed your expectations. For more information or to make a purchase, contact us at xcmotors@163.com. Let us help you optimize your operations with the best 1440 RPM motor for long-lasting performance!

References

1. International Electrotechnical Commission. "IEC 60034-30-1:2014 Rotating Electrical Machines - Efficiency Classes of Line Operated AC Motors." Geneva: IEC Publications, 2014.

2. de Almeida, Anibal T., et al. "Energy-Efficient Motor Systems in the Industrial and in the Services Sectors in the European Union." Energy Policy, vol. 71, 2014, pp. 108-120.

3. Boldea, Ion, and Syed A. Nasar. "The Induction Machines Design Handbook, Second Edition." CRC Press, 2010.

4. European Commission. "Commission Regulation (EU) No 547/2012 Implementing Directive 2009/125/EC with Regard to Ecodesign Requirements for Water Pumps." Official Journal of the European Union, 2012.

5. Waide, Paul, and Conrad U. Brunner. "Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems." International Energy Agency Working Paper, OECD/IEA, 2011.

6. IEEE Standards Association. "IEEE Standard 112-2017 - IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." Institute of Electrical and Electronics Engineers, 2018.