6600V Motor installation demands strict adherence to safety protocols and performance standards to ensure optimal operation in industrial environments. High-voltage motor systems require specialized installation procedures that comply with international standards such as IEC 60034 and JJB/T12730. Proper installation encompasses electrical safety measures, mechanical alignment protocols, grounding systems, and protection ratings like IP54. These standards guarantee reliable operation across demanding applications in power generation, manufacturing, and process control industries where medium-voltage motors deliver exceptional performance and longevity.

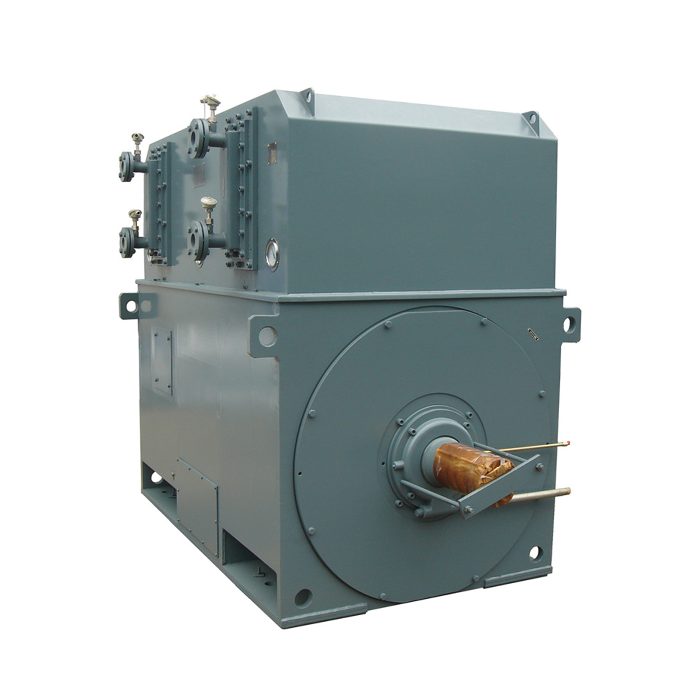

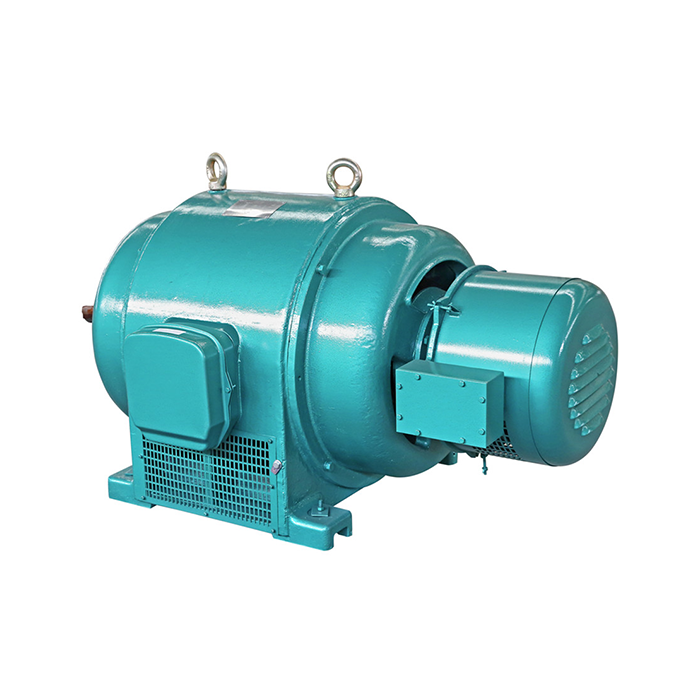

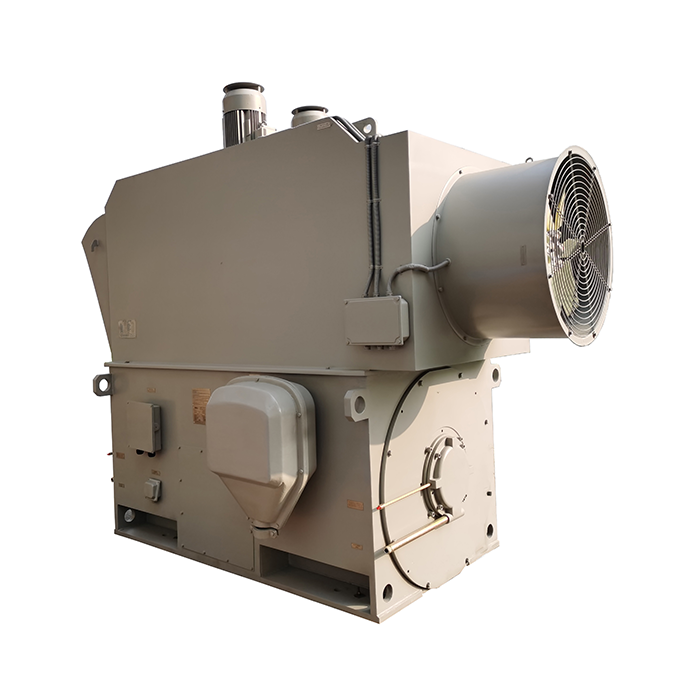

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High-Voltage Motor Requirements

High-voltage engine establishments display interesting challenges that recognize them from standard low-voltage frameworks. The electrical characteristics of medium-voltage hardware require specialized taking care of strategies and security gear. The workforce working with these frameworks must have suitable certifications and preparation in high-voltage security protocols.

Voltage ranges crossing 3000V to 11000V require improved separator frameworks and assurance measures. The cover course F rating gives temperature resistance up to 155°C, whereas the discretionary lesson H cover expands this capability to 180°C. This temperature administration becomes pivotal in applications including compressors, pumps, and mechanical equipment where nonstop operation creates critical warm loads.

Power appraisals from 200kW to 6300kW require vigorous mechanical establishments able to deal with considerable torque and vibration strengths. The engine outline development utilizes cast press plans that give amazing strength against unforgiving natural conditions commonly experienced in mining, cement production, and steel process applications.

Essential Safety Protocols During Installation

Safety remains the foremost concern throughout the establishment preparation of high-voltage engine frameworks. Appropriate lockout/tagout methods must be established and confirmed at some time recently before starting any establishment work. All staff included in the establishment ought to wear fitting individual defensive gear counting arc-rated clothing, protective gloves, and security glasses. The work range must be clearly stamped, and electrical separation must be affirmed with calibrated equipment.

Critical Electrical Safety Procedures

Electrical confinement methods require confirmation utilizing calibrated voltage discovery gear. The establishment region ought to be clearly stamped with suitable caution signs and boundaries to avoid unauthorized access. Grounded security frameworks must be tried and confirmed operational some time recently energizing the engine framework. These foundational steps are non-negotiable for relieving the extreme dangers related to high-voltage environments.

Integrated Protection System Design

The 6600V motor control systems incorporate multiple safety layers, including emergency stop circuits, thermal protection, and current monitoring devices. These protection systems work in conjunction with motor starters and variable frequency drives to provide comprehensive operational safety for the 6600V Motor. The copper rotor bars and end rings are specifically designed to handle fault currents safely while maintaining system integrity under demanding conditions.

Environmental Safety Considerations

Environmental considerations play a noteworthy part in security planning. The IP54 security rating guarantees satisfactory tidiness and dampness resistance in commonplace mechanical situations. In any case, establishments in especially cruel conditions may require extra natural security measures counting specialized containment areas or climate control frameworks to guarantee the long-term secure operation of the introduced equipment.

Performance Standards and Compliance

Meeting Electrical Installation Standards

Meeting performance standards requires careful attention to both electrical and mechanical parameters throughout the installation process. Motor efficiency ratings directly correlate with proper installation practices including accurate alignment, appropriate foundation design, and correct electrical connections. The JB/T12729 standard outlines specific performance criteria for medium-voltage induction motors, including the 6600V Motor. Compliance with these standards ensures reliable operation and longevity across various industrial applications. Performance testing protocols should be implemented to verify motor characteristics such as speed regulation, torque output, and efficiency measurements, which are crucial for validating that the installation meets the rigorous demands of industrial operation.

Ensuring Winding and Insulation Integrity

The integrity of motor windings, particularly for a 6600V Motor, is paramount for safe and efficient operation. The 6600V motor winding configurations require precise installation procedures to maintain insulation integrity. The vacuum pressure impregnation process used during manufacturing must be protected during installation through careful handling and strict environmental controls to prevent moisture ingress or physical damage. Any compromise to this winding insulation can lead to partial discharge, short circuits, and ultimately catastrophic failure, posing significant safety hazards and causing extensive operational downtime, underscoring the critical nature of meticulous installation practices.

Optimizing Cooling and Mechanical Performance

Cooling system performance directly impacts motor efficiency, reliability, and operational lifespan. Proper installation of cooling fans, heat exchangers, and ventilation systems is essential to ensure adequate thermal management and prevent overheating under load. Furthermore, the low noise and low vibration characteristics inherent to quality motors, such as a properly installed 6600V Motor, are entirely dependent on precise mechanical installation and alignment procedures. Accurate shaft alignment and a stable foundation are crucial to minimize mechanical stresses, reduce bearing wear, and achieve the smooth, quiet, and efficient performance that defines a successful industrial motor installation.

Mechanical Installation Considerations

The foundation plan speaks to a basic viewpoint of fruitful engine establishment. The establishment must give satisfactory mass and unbending nature to retain operational powers, while keeping up exact arrangement resiliences. Concrete establishments ought to remedy totally some time recently engine establishment begins.

Shaft arrangement methods require accurate measuring hardware and experienced professionals. Misalignment can result in untimely bearing disappointment, expanded vibration, and diminished productivity. SKF, NSK, and FAG bearing frameworks utilized in quality engines require careful handling and legitimate installation methods to accomplish their planned life expectancy.

Coupling choice and establishment altogether affect, by and large, the framework execution. Adaptable couplings suit minor misalignments whereas transmitting torque proficiently. The coupling establishment handle ought to take after producer details with respect to fit resistances and grease requirements.

Vibration checking frameworks ought to be introduced amid starting setup to build up pattern estimations. These frameworks empower prescient upkeep programs that can distinguish creating issues some time recently they result in disastrous disappointments. Normal vibration examination makes a difference in optimizing upkeep plans and maximizing gear availability.

Electrical Connection and Protection Systems

Electrical connections for high-voltage motors require specialized techniques and materials rated for the operating voltage. Cable selection must consider not only current-carrying capacity but also insulation ratings, environmental resistance, and mechanical protection requirements.

Terminal box connections represent potential failure points requiring careful attention during installation. All connections should be torqued to manufacturer specifications and protected against environmental contamination. High-voltage connections often utilize specialized connectors designed for medium-voltage applications.

6600V motor protection systems integrate multiple monitoring functions including overcurrent, undervoltage, phase loss, and thermal protection. These systems work in conjunction with motor starters to provide comprehensive equipment protection. Protection relay coordination ensures selective operation during fault conditions.

Grounding systems for medium-voltage motors require special consideration due to the higher energy levels involved. Equipment grounding must provide adequate fault current paths while maintaining low resistance connections. Regular testing of grounding system integrity should be incorporated into maintenance procedures.

Testing and Commissioning Procedures

Comprehensive testing procedures validate both safety systems and performance characteristics before placing motors into service. Insulation resistance testing verifies winding integrity using appropriate high-voltage testing equipment. These tests should be performed at multiple stages during the installation process.

Performance testing includes measurement of key parameters such as current draw, power factor, and efficiency at various load conditions. Baseline measurements establish reference points for future condition monitoring and maintenance activities. All test results should be documented and retained for future reference.

6600V motor fault diagnosis capabilities should be demonstrated during commissioning. Protection systems must respond appropriately to simulated fault conditions including overcurrent, phase imbalance, and thermal overload scenarios. Proper operation of emergency stop systems requires verification under actual operating conditions.

Operational training for maintenance personnel should be completed before final commissioning. This training should cover normal operating procedures, emergency response protocols, and routine maintenance requirements. Documentation including operation manuals, maintenance schedules, and spare parts recommendations, should be provided to facility personnel.

Conclusion

Successful 6600V motor installation requires meticulous attention to safety protocols, performance standards, and specialized determinations. Legitimate establishment hones guarantee solid operation, maximizes hardware life, and maintains secure working conditions. The combination of fitting security measures, exact mechanical establishment, and comprehensive testing strategies makes the establishment for a long time of, trouble-free operation. Collaborating with experienced providers and taking after built up benchmarks gives the certainty required for basic mechanical applications where unwavering quality and execution cannot be compromised.

Partner with XCMOTOR for Superior 6600V Motor Solutions

XCMOTOR delivers exceptional 6600V motor supplier expertise backed by comprehensive installation support and technical guidance. Our experienced engineering team provides on-site commissioning services, ensuring your high-voltage motor systems meet all safety and performance standards from day one. With original parts from trusted brands, fast delivery options, and dedicated support including weekends, we guarantee reliable power solutions for your critical industrial applications. Ready to enhance your facility's performance with premium motor technology? Contact us at xcmotors@163.com today.

References

1. International Electrotechnical Commission. "IEC 60034-1: Rotating electrical machines - Part 1: Rating and performance." Geneva: IEC Publications, 2017.

2. Institute of Electrical and Electronics Engineers. "IEEE Standard 112-2017: IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." New York: IEEE Press, 2018.

3. National Electrical Manufacturers Association. "NEMA MG 1-2016: Motors and Generators Standards Publication." Rosslyn: NEMA Publications, 2016.

4. China National Standards. "JB/T 12730-2016: Three-phase asynchronous motors for general purposes - Technical conditions." Beijing: Standards Press of China, 2016.

5. International Organization for Standardization. "ISO 12100-2010: Safety of machinery - General principles for design." Geneva: ISO Publications, 2010.

6. American National Standards Institute. "ANSI/IEEE C57.12.00-2015: IEEE Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers." New York: IEEE Standards Association, 2015.