The 20 HP DC electric motor represents the pinnacle of precision speed control technology in industrial automation. These powerful machines deliver exceptional torque characteristics and variable speed capabilities that make them indispensable across manufacturing sectors. From robotics to process control systems, 20 horsepower DC motors provide the reliability and performance that modern industries demand for maintaining competitive operations and achieving optimal productivity.

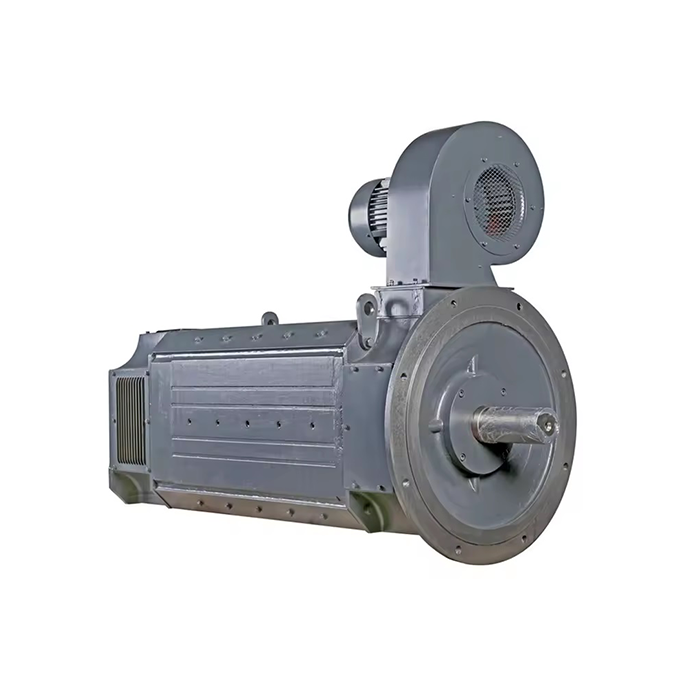

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding DC Motor Technology in Industrial Applications

Due to their speed control, DC motors have transformed industry. These electric drives regulate rotational speed and torque more precisely than AC drives. This electromagnetic design lets operators immediately modify performance parameters, making it excellent for applications with frequent speed variations.

Smooth power supply comes from the armature and commutator. This arrangement allows the motor controller to work consistently under different loads. This technique saves energy and boosts efficiency for industries. Modern DC power supplies have improved these motors. Advanced motor winding improves power efficiency, while advanced motor cooling systems provide long-term reliability. This makes industrial motors more reliable than before.

Core Applications of 20 Horsepower DC Motors

Manufacturing and Machine Tools

Manufacturing facilities rely heavily on precise motor control for machine tools. The 20 HP configuration provides adequate power for metal cutting operations, drilling equipment, and automated assembly lines. These motors excel in environments where load capacity varies frequently throughout production cycles. Machine tool applications benefit from the instant torque response that DC technology provides. Operators can adjust cutting speeds immediately based on material requirements. This flexibility reduces waste and improves product quality across automotive, aerospace, and electronics manufacturing sectors.

Process Control Systems

Chemical plants and refineries depend on reliable pump and compressor operations. 20 HP DC Electric Motors offer the speed regulation needed for maintaining consistent flow rates and pressure levels. The motor shaft delivers steady rotational force that keeps critical processes running smoothly. These systems often require emergency speed adjustments during process upsets. The responsive nature of DC drive technology allows operators to make rapid corrections without shutting down entire production lines. This capability saves both time and money in high-value manufacturing environments.

Material Handling and Conveyor Systems

Warehouses and distribution centers use conveyor systems extensively for moving products efficiently. Variable speed control becomes essential when handling different package sizes and weights. The brushless motor design reduces maintenance requirements while providing consistent performance. Load capacity management becomes critical in these applications. DC motors adjust automatically to changing belt tensions and cargo weights. This adaptability prevents system overloads and extends equipment lifespan significantly.

Robotic and Automation Equipment

Industrial robotics demand precise positioning and smooth acceleration profiles. The electromagnetic characteristics of DC motors provide the fine control needed for assembly operations, welding applications, and pick-and-place systems. Robotic systems benefit from the low motor maintenance requirements of modern DC designs. Extended operation periods between service intervals keep production lines running continuously. The motor insulation systems protect against harsh industrial environments commonly found in automated facilities.

Printing and Paper Processing

Commercial printing operations require extremely precise speed synchronization between multiple drive points. DC motors provide the stability needed for maintaining paper tension and print registration. Web handling applications particularly benefit from this technology. Paper mills use these motors for controlling roll speeds during manufacturing processes. The ability to maintain constant surface speeds regardless of roll diameter changes improves product quality. This precision reduces waste and increases overall production efficiency.

Food Processing and Packaging

Food manufacturing facilities need sanitary motor designs that can withstand frequent washdowns. Modern DC motors feature enhanced motor cooling systems and improved sealing that meets industry hygiene standards. Packaging equipment relies on precise timing for filling, sealing, and labeling operations. The responsive speed control allows manufacturers to handle different product types without extensive changeover procedures. This flexibility improves production scheduling and reduces downtime.

Textile and Fiber Production

Textile mills require consistent tension control throughout fiber processing operations. DC motors provide the smooth speed regulation needed for spinning, weaving, and dyeing processes. The energy consumption characteristics help reduce operational costs in energy-intensive textile operations. Fiber quality depends heavily on maintaining proper processing speeds. Variable speed capability allows operators to optimize conditions for different material types. This control improves product consistency and reduces material waste during production runs.

Technical Advantages and Performance Benefits

20 HP DC Electric Motors are ideal for demanding industrial applications due to their high torque. High starting torque allows these machines to operate reliably with big loads. The linear speed-torque connection ensures consistent performance across all operating conditions. Modern motor controllers have greatly increased power efficiency. Digital control systems improve energy usage by automatically altering motor characteristics depending on demand. Operating expenses are reduced while performance is optimized using this information.

Advanced bearing systems and motor insulating materials have reduced motor maintenance. Under extreme circumstances, SKF, NSK, and FAG bearings last longer. These components decrease unexpected downtime and TCO. Modern DC motors are small, making installation easier in tight spaces. Frame sizes 100-450 allow diverse mounting configurations without affecting performance. This adaptability makes them appropriate for new and retrofit installations.

Speed Control Technologies and Implementation

Modern speed regulation systems employ sophisticated electronic controls that provide precise motor operation. Digital controllers monitor motor shaft position and speed continuously, making real-time adjustments to maintain setpoint accuracy. This technology enables applications requiring positioning accuracy within fractions of a degree.

The electric drive systems integrate seamlessly with plant automation networks. Communication protocols allow remote monitoring and control of motor parameters from central control rooms. Operators can adjust speeds, monitor performance, and diagnose issues without visiting individual motor locations.

Regenerative braking capabilities recover energy during deceleration cycles. This feature becomes particularly valuable in applications with frequent speed changes or positioning moves. The recovered energy reduces overall energy consumption and improves system efficiency.

Installation and Integration Considerations

Proper motor installation requires careful attention to environmental conditions and mounting arrangements. The IP23 protection rating provides adequate protection for most indoor industrial environments. Applications requiring higher protection levels can specify enhanced enclosures without affecting motor performance.

Electrical connections must accommodate the specific voltage requirements of each application. Standard voltage ranges include 160V and 440V configurations, with custom voltages available for special applications. Proper grounding and motor insulation verification ensure safe operation and regulatory compliance.

Integration with existing equipment requires consideration of mechanical coupling methods and alignment procedures. The motor shaft specifications must match driven equipment requirements to prevent premature bearing failure or vibration issues. Professional installation services ensure optimal performance and reliability.

Industry Standards and Certifications

Quality assurance becomes critical when selecting industrial motors for demanding applications. Motors complying with GB/T755 national standards and VDE0530 international specifications provide assurance of reliable performance and safety compliance.

ISO 9001:2015 certification demonstrates manufacturer commitment to quality management systems. This certification ensures consistent manufacturing processes and rigorous testing procedures. CE marking confirms compliance with European safety directives for industrial equipment.

Third-party testing validates motor performance claims and safety characteristics. Independent laboratories verify efficiency ratings, load capacity specifications, and environmental protection levels. This validation provides confidence in motor selection decisions for critical applications.

Maintenance and Lifecycle Management

Preventive maintenance extends motor life and boosts performance. Regular motor cooling, bearing, and electrical connection inspections avoid expensive breakdowns. Vibration monitoring can spot issues before they harm equipment. Operating parameters and load factors determine bearing replacement schedules. Quality bearings from recognized suppliers last longer under typical use. Bearing performance is optimized throughout the motor lifespan with proper lubrication. Older motors may operate like new with motor rewinding. For big frame motors, professional rewinding utilizing contemporary motor winding processes and insulating materials is sometimes cheaper than replacement. It prolongs equipment life and maintains performance.

Cost-Effectiveness and ROI Analysis

Quality DC motors save money and energy. Power efficiency impacts multi-motor facility running expenses. Within months, energy savings might justify luxury car purchases. Motor reliability saves money beyond energy by reducing downtime. Production continuity prevents late delivery fines and meets customer delivery deadlines. Competitive markets value reliability higher. Longer equipment life reduces replacement and installation costs. Good cars can survive decades. These durable industrial assets are ideal long-term investments.

Motors with sensors and communication are smart. These traits help predictive maintenance plan repairs and prevent unexpected failures. Global internet allows remote monitoring and diagnosis. Advanced motor controller algorithms improve performance. Motor functioning is optimized by machine learning utilizing performance data and application-specific criteria. These innovations increase motor reliability and energy efficiency. Environmental issues drive motor technology sustainability. Manufacturing environmental impact reduction and motor component recycling help firm sustainability goals. Future motor selection criteria will reflect these developments.

Conclusion

The versatility and performance of 20 HP DC electric motors make them essential components in modern industrial operations. Their precision speed control capabilities, combined with robust construction and advanced technology, deliver reliable solutions across diverse applications. From manufacturing automation to process control systems, these motors provide the performance and efficiency that competitive industries require. Investment in quality DC motor technology pays dividends through improved productivity, reduced energy costs, and enhanced operational reliability that keeps businesses running smoothly.

Frequently Asked Questions

Q1: What makes DC motors better than AC motors for speed control applications?

A: DC motors provide superior speed regulation capabilities due to their linear speed-torque characteristics and responsive control systems. They offer precise speed adjustment across wide ranges without the complexity required for AC motor variable speed drives. The electromagnetic design enables instant torque response and smooth speed transitions that many applications require.

Q2: How do I determine if a 20 HP motor is adequate for my application?

A: Motor sizing depends on load requirements, duty cycle, and environmental conditions. Calculate the maximum torque and power requirements for your application, including starting loads and peak operating conditions. Consider factors like acceleration time, load capacity variations, and safety margins when selecting motor power ratings.

Q3: What maintenance is required for industrial DC motors?

A: Regular maintenance includes bearing lubrication, brush inspection (for brushed motors), motor cooling system cleaning, and electrical connection verification. Vibration monitoring and thermal imaging can detect developing problems early. Most quality motors require minimal maintenance when operated within design parameters and environmental specifications.

Choose XCMOTOR for Your Industrial Motor Solutions

XCMOTOR stands as your trusted 20 HP DC electric motor manufacturer, delivering precision-engineered solutions for demanding industrial applications. Our commitment to quality ensures every motor meets international standards while providing exceptional value. We offer fast delivery, comprehensive technical support, and 30-day return policies that demonstrate confidence in our products. Ready to enhance your operations with reliable motor technology? Contact us at xcmotors@163.com for expert consultation and competitive pricing on industrial motor solutions.

References

1. Hughes, Austin. "Electric Motors and Drives: Fundamentals, Types and Applications." 4th Edition, Newnes Publishing, 2019.

2. Fitzgerald, A.E., Kingsley, Charles Jr., and Umans, Stephen D. "Electric Machinery." 7th Edition, McGraw-Hill Education, 2021.

3. Chapman, Stephen J. "Electric Machinery Fundamentals." 5th Edition, McGraw-Hill Science/Engineering/Math, 2020.

4. Toliyat, Hamid A. and Kliman, Gerald B. "Handbook of Electric Motors." 2nd Edition, CRC Press, 2018.

5. Miller, T.J.E. "Brushless Permanent-Magnet and Reluctance Motor Drives." Oxford University Press, 2019.

6. Sen, P.C. "Principles of Electric Machines and Power Electronics." 3rd Edition, John Wiley & Sons, 2021.