2500 kW Motor Testing: Ensuring Performance Before Shipping

Before shipping, testing a 2500 kW Motor is an important part of quality control that makes sure the motor works well, is reliable, and meets industry standards. We do thorough inspections before shipping to look for possible problems, confirm wiring specs, and make sure the mechanical integrity. This strict testing method cuts down on mistakes in the field, keeps operations running smoothly, and ensures that your high-power motor investment will work well from the first day it is installed.

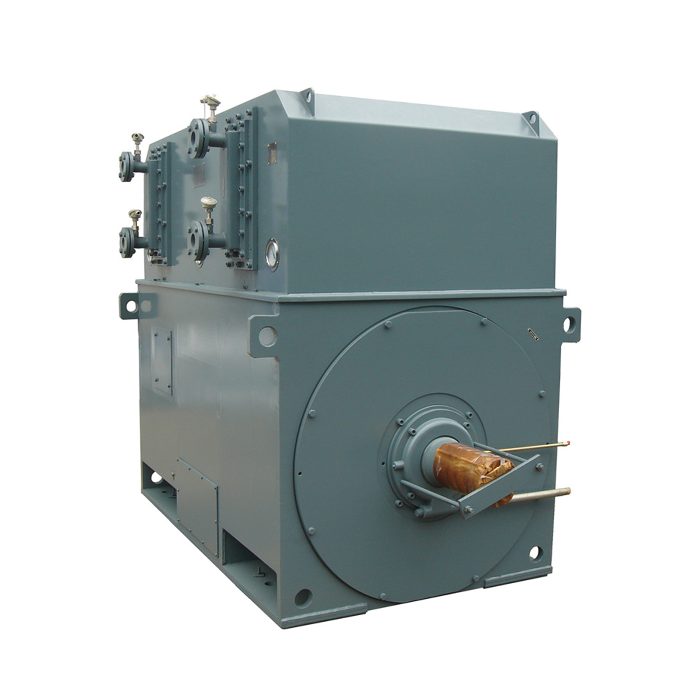

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Introduction

Before shipment, 2500 kW motors must be tested for performance, reliability, and industry requirements. Energy efficiency, operational downtime, and customer happiness are improved by rigorous testing. Understanding the extent and impact of these tests helps B2B procurement professionals make educated decisions, avoid risks associated with major motor expenditures, and comply with strict technical and contractual standards. Power generating, water treatment, and manufacturing facilities depend on these strong motors for mission-critical operations. Unexpected high-power motor failures can cause production losses, safety concerns, and regulatory compliance challenges. Final pre-shipment testing ensures your motor investment will function well under severe operational conditions.

Understanding 2500 kW Motor Testing: Key Aspects and Importance

Performance validation and essential testing parameters

These high-power motors are tested for power output, torque characteristics, and cooling system efficiency, which affect operating performance. Our testing processes ensure motors work successfully across power grid configurations by checking electrical factors including voltage tolerance ranges from 3000V to 11000V. Environmental exposure tests imitate real-world situations to verify IP54 protection.

Avoiding costly downtime, warranty claims, and inefficiencies throughout use requires rigorous pre-shipment testing. Each motor is performance validated to handle water pumps, compressors, cutting machine tools, and transportation gear. The innovative rotor design is tested carefully to assure vibration-free operation under heavy loads.

Quality assurance and international standards compliance

International standards like JB/T 12730 and 12729 ensure testing quality worldwide. These standards specify test methodologies, acceptance criteria, and documentation requirements for motor dependability across industrial contexts. To meet global procurement standards, our testing laboratory uses calibrated equipment and methods.

Electrical insulation, mechanical integrity, thermal stability, vibration, noise, and operational efficiency tests are common. Each test verifies motor readiness and regulatory and contractual compliance in B2B procurement.

Core Testing Methods and Performance Metrics for 2500 kW Motors

Electrical Testing and Insulation Verification

Electrical tests like insulation resistance and winding resistance are the first step in testing high-power motors. Our innovative testing equipment ensures motor insulation over their voltage range, preventing electrical problems. To ensure electrical component insulation, vacuum pressure impregnation procedures are validated.

Power factor verification, phase balance analysis, and surge withstand capability testing are also electrical tests. These tests keep motors running efficiently within their electrical parameters while protecting against industrial voltage variations and grid interruptions. For larger applications, the 2500 kW Motor undergoes the same rigorous testing procedures to ensure optimal performance under high-power conditions.

Dynamic Performance Analysis and Mechanical Evaluations

Precision measurement equipment are used to verify shaft alignment, bearing performance, and vibration analysis. Dynamic balancing is carefully tested to ensure smooth operation and avoid mechanical stress that could prematurely damage components. We test SKF, NSK, and FAG bearings to ensure they meet performance standards.

Energy efficiency testing follows motor performance criteria, while environmental impact studies evaluate noise and heat emissions. Duty cycle models simulate real-world load scenarios to test motor response and thermal management.

Quality Assurance and Defect Identification Protocols

Insulation degradation, thermal management concerns, and mechanical misalignment can be identified for quick troubleshooting and quality assurance. Our tests identify issues before they become field failures, ensuring motors exceed global industrial performance standards. Each motor comes with detailed performance and test results documentation.

We use advanced diagnostics to assess motor performance under simulated operating stress and discover parameter discrepancies. Our proactive approach ensures that only high-quality motors reach customer premises.

Comparative Analysis: Ensuring Your 2500 kW Motor Outperforms Industry Alternatives

Performance Benefits and Technical Details

High-power motors differ in torque capacity, operational efficiency, and energy consumption, which helps buyers choose the best option. Our motors' cast frame structure provides stability and thermal dissipation for long-term performance. Smooth, vibration-free performance from the improved rotor design enhances operational longevity and reduces maintenance.

Thermal management and testing results depend on cooling system performance, affecting motor longevity and operating dependability. Our IC611 cooling technology dissipates heat better than air-cooled competitors, providing constant performance under severe operational situations. Continuous duty cycles and high ambient temperatures make thermal control crucial.

Drive Configuration and System Integration Benefits

Different drive configurations affect mechanical stress testing and maintenance planning. Our motors have optimised designs for direct drive and belt drive applications and testing processes for each. Testing showed low noise and vibration, which improves operational environments and reduces mounting system stress.

Inverter system compatibility testing ensures motor control integration and reduces harmonic distortion, which can influence operational stability in complicated industrial applications. Our testing checks motor performance across control schemes to ensure dependable operation independent of drive system configuration.

Optimizing Procurement Decisions Through Testing Insights

Data-driven supplier risk assessment

Supplier assessments with detailed motor test results improve B2B procurement decisions by revealing product reliability, operational efficiency, and regulatory compliance. Our extensive testing data includes performance curves, thermal properties, and mechanical requirements for comparison with alternatives. Data openness helps procurement professionals make operationally relevant judgements.

Recognising how rigorous testing affects lead times, warranty conditions, and after-sales assistance helps buyers match vendor capabilities with operational requirements. For instance, when evaluating larger motors like the 2500 kW Motor, comprehensive test data ensures that the motor meets both performance and reliability standards. To ensure complete validation without delays, our testing processes balance thoroughness and delivery timelines. Testing rigour and warranty coverage provide value beyond original purchases.

Customisation and App-Specific Testing

Custom and large orders require application-specific testing techniques to validate performance and boost supply chain confidence. Our testing services meet power generation and water treatment needs. Different application environments require different validation methods.

Motor integrity is checked throughout shipping to ensure product performance upon arrival and installation. Our packaging and handling processes retain pre-shipment performance test results, protecting your investment during delivery.

Maintenance Tips and Longevity Based on Pre-Shipment Testing Insights

Develop Predictive Maintenance Strategy

Pre-shipment test data is essential for predictive maintenance systems that monitor vibration, temperature, and performance to prevent unexpected failures. Initial testing establishes baseline measurements for future condition monitoring programs. Maintenance teams can anticipate issues before they affect operational availability with this proactive approach.

Test vibration signatures define normal operating norms that maintenance staff can utilise to detect bearing wear, misalignment, and other mechanical faults. Thermal testing temperature profiles give baseline data for thermal monitoring programs to detect cooling system degradation or electrical issues.

Optimising Operations and Monitoring Performance

Testing failure analysis helps avoid maintenance mistakes and promotes motor care and operational management best practices. Our testing documentation recommends operational conditions to maximise motor lifespan and performance. Regular benchmark-based performance monitoring optimises load management and schedules timely repairs to extend motor life.

Efficiency in motor operation decreases environmental effect and reinforces corporate responsibility in industrial energy management. Testing confirmed minimal energy use, which lowers operational costs and improves environmental performance.

XCMOTOR: Your Trusted Partner for High-Performance Motor Solutions

XCMOTOR is a 2500 kW Motor manufacturer recognised worldwide for its superior motor testing and rigorous adherence to international quality standards. Before shipment, our rigorous testing processes ensure every motor fulfils performance, durability, and operational dependability standards. Each item is rigorously validated to meet JB/T 12730 and 12729 standards and surpass customer quality and performance objectives. Our dedication to excellence extends beyond manufacturing to customised solutions, strong after-sales services, and extensive warranty coverage. Our rigorously verified items are delivered safely by XCMOTOR's global logistics network. Technical support from our specialised support staff uses each motor's extensive testing data.

XCMOTOR products have low noise, low vibration, prolonged service life, and easy installation and maintenance. Our rigorous testing and quality-focused manufacturing procedures prioritise long-term client satisfaction. Our variable bearing options include SKF, NSK, and FAG per customer requirements. Our 200-6300 kW power range and 3000V–11000V voltage allow us to serve fans, water pumps, compressors, crushers, cutting machine tools and transportation machinery. IP54 protection and innovative cooling systems provide reliable performance in harsh industrial conditions.

Conclusion

Quality assurance testing of 2500 kW motors before shipment provides performance, compliance, and operational risk reduction for industrial customers. The detailed testing techniques in this book show the need of rigorous review before motor deployment. The testing techniques protect large capital expenditures and ensure reliable operation in demanding industrial applications. XCMOTOR's strict testing standards, wide manufacturing capabilities, and customer-focused support make us the ideal partner for high-power motors. Our testing processes guarantee that your motor investment will function consistently and meet your industrial application's operating needs.

FAQ

1. What are the most important high-power motor pre-shipment tests?

Electrical insulation testing, load and no-load performance testing, vibration analysis, noise level assessment, and operational efficiency validation are essential pre-shipment tests. These tests verify motor performance under diverse operating situations and operational dependability and regulatory compliance.

2. How does testing data affect procurement?

Testing data provides accessible benchmarks for motor efficiency, operational durability, and regulatory compliance, making it crucial to procurement. This data allows impartial comparison of motor option performance, warranty terms, and long-term operational costs to support supplier selection decisions.

3. Do custom motors need special testing?

Special motors receive extensive testing to meet their operating and environmental needs. These specialised tests validate standard design changes and provide performance consistency across specialised applications. Custom testing techniques may include environmental simulation, application-specific load profiles, or mounting configuration validation.

Contact XCMOTOR for Your Motor Testing and Procurement Needs

Want reliable, well-tested motor solutions for your industrial operations? XCMOTOR's skilled engineers offer motor testing, customisable design, and quick technical support to match your operational needs. From installation to years of operation, our stringent pre-shipment testing methods ensure your 2500 kW Motor investment is reliable and performant.Contact our specialists at xcmotors@163.com to discuss your project requirements and experience the assurance that comes with partnering with a trusted 2500 kW Motor supplier committed to excellence.

References

1. Industrial Motor Testing Standards and Quality Assurance Protocols" - Institute of Electrical and Electronics Engineers Standards Publication, 2023.

2. High-Power Motor Performance Validation and Pre-Shipment Testing Procedures" - International Electrotechnical Commission Technical Report, 2022.

3. Quality Control in Electric Motor Manufacturing: Testing Methodologies and Best Practices" - Society of Manufacturing Engineers Technical Paper Series, 2023.

4. Predictive Maintenance Strategies Based on Motor Testing Data Analysis" - Reliability Engineering and Maintenance Planning Journal, 2022.

5. Energy Efficiency Standards for Industrial Motors: Testing and Compliance Requirements" - American Society of Mechanical Engineers Performance Test Codes, 2023.

6. Vibration Analysis and Dynamic Testing of Large Industrial Motors" - Condition Monitoring and Diagnostic Engineering Management Conference Proceedings, 2022.