Top Features to Look for in a 4000 kW Motor

For industrial uses, choosing a 4000 kW motor and knowing what aspects are most important is essential to its success. These large motors are very important in many different types of manufacturing, power creation, and process control systems. Choosing the right motor has a direct effect on how much energy it uses, how much it costs to run, and how reliable it is in the long run. Strong construction, advanced cooling systems, exact voltage compatibility, and full protection ratings that ensure consistent performance in harsh environments are some of the most important things to look at.

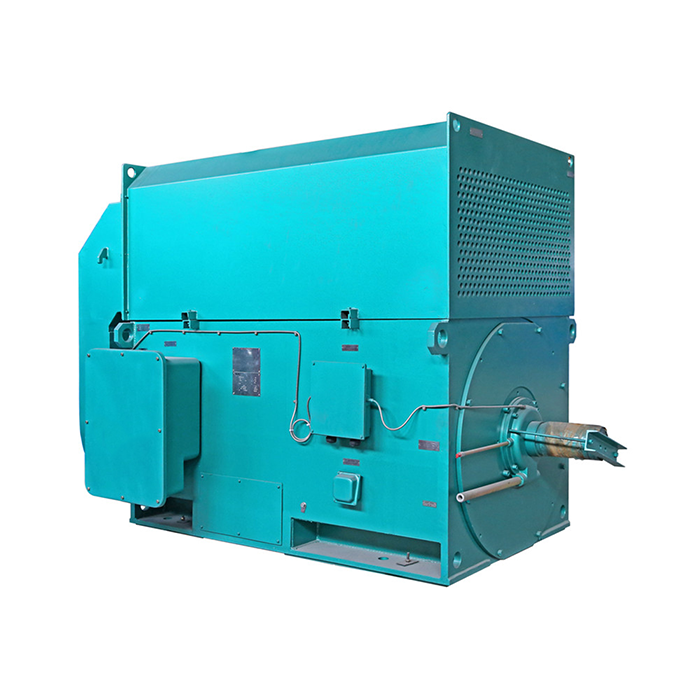

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Core Specifications of a 4000 kW Motor

Output power and electrical specs

A high-capacity motor's ability to work in a wide range of industrial settings depends on its basic electrical properties. Modern motors with power ranges from 200 to 3150 kW are very flexible and can meet a wide range of industrial needs. It's important to know about voltage compatibility, and the standard choices are 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, and 11000V±5%.

These voltage ranges work with a variety of power distribution methods that are used in factories around the world. The precise voltage range makes sure that the system works steadily and keeps sensitive equipment safe from changes in the voltage. The frequency range of 50 Hz is in line with worldwide power grid standards, and the speed range of 500 to 3000 RPM makes it useful for a variety of mechanical tasks.

Power Factor and Efficiency Metrics Things to Think About

Energy efficiency is a very important thing to think about when choosing a motor because it has a direct effect on prices and environmental compliance. More than 95% of modern high-capacity motors are efficient, which means they use a lot less energy than older types. Power factor optimisation makes sure that the electrical system transfers the most power possible while losing the least amount of reactive power possible.

Starting currents, which are usually between 5 and 7 times the rated current, affect the needs for electrical infrastructure and the design of safety systems. 60–80% of the maximum torque for starting torque makes sure that the equipment starts up reliably even when it's loaded, which keeps the mechanical parts from getting stressed and the electrical parts from having problems while it's running.

Needs for maintenance and features that make it reliable

Preventive repair plans greatly increase the life of motors while keeping them running at their best. Advanced bearing systems, which can use SKF, NSK, or FAG bearings, are very reliable and don't need to be serviced as often. Compared to traditional bearing configurations, anti-friction bearings reduce wear and the amount of upkeep that needs to be done.

PT100 temperature sensors are carefully placed in the stator windings and bearing assemblies as part of thermal protection systems. These monitoring systems let you plan repair ahead of time and stop expensive equipment breakdowns before they happen by sending out early warning signals.

Essential Performance and Design Features to Evaluate

Building motors and protecting the environment

For industrial motor uses, the construction needs to be strong so that it can handle harsh working conditions. Cast iron frames are very strong and don't vibrate easily, which is important for factories that need to run all the time. It is recommended that you use the IP54 protection standard for most industrial settings because it provides enough protection against dust and water spray.

Rotors that are precisely balanced reduce vibrations, increase the life of bearings, and lower noise levels. Modern cooling systems keep things at the best temperatures even when they are constantly under a lot of stress. For large-scale applications like the 4000 kW motor, these design features are essential to ensure consistent performance. All of these design elements work together to make the service life longer and the upkeep needs lower.

Class of Insulation and Temperature Control

When winding systems are working with different loads, insulation class grades of F or H offer better thermal protection. Up to 155°C can be reached by Class F insulation, and up to 180°C can be reached by Class H insulation. This thermal capability makes sure that the device will work reliably in high-temperature settings that are popular in industrial settings.

Modern cooling systems get rid of the heat that is made during operation so that the system keeps working well even when the outside temperature changes. Keeping an eye on the temperature stops insulation from breaking down and greatly increases the motor's general life span.

Control of Noise and Vibration

Noise reduction and sound control are important parts of modern motor designs that make workplaces safer and more comfortable. Noise levels below 85 dB(A) meet safety standards for the workplace and are better for the environment. Precision balancing methods keep vibrations from reaching equipment and buildings that are connected to them.

These changes to the noise level make the workplace safer and protect sensitive equipment from damage caused by vibrations. Lower noise levels also make it easier for people to talk to each other in industrial facilities, which improves the general efficiency of operations.

How to Choose the Best 4000 kW Motor for Your Industrial Needs

Assessment of Application-Specific Requirements

In different industrial settings, motor function and design must meet different standards. Compressors need exact speed control and thermal management, while water pumps need reliable starting torque and the ability to run continuously. Crushers and other cutting machines need to be built to last and be able to handle a lot of weight.

When it comes to transportation machinery, applications that focus on dependability and easy upkeep are more important than those that focus on energy efficiency and noise control. Understanding these application-specific needs helps you choose the right motor and makes sure it works at its best for the whole life of the equipment.

Standards for compliance and quality assurance

When choosing an industrial motor, it's important to look at the appropriate quality certifications and compliance standards. The JB/T 12730 and JB/T 12729 standards make sure that motors for commercial use meet strict performance and safety standards. These standards cover things like mechanical building, electrical performance, and the ability to protect the environment.

Processes for quality control, like precise die-casting, advanced winding methods, and vacuum pressure impregnation, make sure that the quality of the products is always the same. Dynamic balancing of rotor parts gets rid of vibration problems, and full testing makes sure that performance specs are met before delivery.

Thoughts on Integration and Installation

To successfully integrate a motor, you need to carefully think about its physical measurements, how it will be mounted, and how it will be connected. Planning ahead makes sure that installation goes smoothly and that there is as little downtime as possible during equipment setup. Integrating systems is easier when they can use the same electrical connections as other control systems.

For large motors like the 4000 kW motor, features that make installation and maintenance easy cut down on labor costs and make equipment easier to access for regular service processes. Clear instructions and technical help make the installation process go more smoothly and make sure that the software works at its best from the start.

Procurement Guidelines for Buying a 4000 kW Motor

Assessing and Selecting Suppliers

Selecting reliable suppliers affects project success and equipment longevity. Manufacturing capability, quality certifications, and technical support should be assessed. Established manufacturers with track histories guarantee product reliability and service continuity.

Technical competence and customisation allow vendors to meet application needs while preserving quality. Warranty and after-sales support preserve investment value and equipment uptime.

Plan Time and Logistics

Industrial motor procurement involves careful planning for production and delivery lead times. Complex customisations or configurations may delay delivery, requiring project timetable coordination. International shipment requires packaging, documentation, and customs clearance.

Bulk purchases can save money and ensure product quality across installations. Delivery scheduling optimises installation operations and reduces storage needs.

Quality Documentation and Certification Needs

Comprehensive documentation aids equipment commissioning, operation, and maintenance. Technical specifications, performance curves, and installation instructions ensure equipment integration, especially for complex systems like the 4000 kW motor. Quality certificates and compliance documents prove compliance with requirements.

Maintenance manuals and replacement parts availability information help equipment last and reduce downtime. Clear warranties and service agreements safeguard investment value and ensure technical support.

About XCMOTOR and Solutions for Your High-Capacity Motor Needs

Manufacturing Excellence and Product Variety

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides power equipment solutions for various industrial applications. Every motor fulfils high performance standards and is reliable thanks to our engineering competence. We make 200-3150 kW motors for 3.3 kV to 11 kV voltages.

Precision die-casting, winding, and vacuum pressure impregnation improve insulation performance in our advanced manufacturing methods. Comprehensive testing validates performance parameters while dynamic balancing ensures smooth operation. These manufacturing standards ensure product quality and worldwide compliance.

Customisation and Tech Support

Some industrial applications demand specific motor designs for best performance. Our engineers work with clients to create customised operational solutions, such as for a 4000 kW motor. We customise cooling systems, mounting layouts, and bearing arrangements to match your needs.

Technical support includes installation, commissioning, and maintenance after product delivery. Our seven-day support team is available when you need it. This comprehensive strategy strengthens our long-term customer partnerships.

Quality and Delivery Promises

Quality assurance ensures every motor satisfies performance specifications before shipment. We use only trustworthy suppliers and strict testing processes during manufacturing. Our use of original parts from trusted companies ensures long-term performance and extensive warranty coverage.

Fast delivery reduces project delays and supports tight installation timelines. Our efficient logistics network ensures product integrity and fast dispatch. Our 30-day return policy ensures client happiness and product selection comfort.

Conclusion

Selecting an industrial motor needs careful consideration of technical requirements, performance, and supplier capabilities. Power output compatibility, environmental protection ratings, and industry requirements are important. Understanding application-specific criteria helps choose the right motor for best performance throughout its lifecycle. Superior motors include superior construction, cooling systems, and protection features. Reliable supplier partnerships ensure maintenance parts and technical support. Effective procurement planning, including lead time management and quality documentation, helps projects and operations succeed.

Frequently Asked Questions

1. What are industrial motor voltage ranges?

To meet power distribution systems, industrial motors work across numerous voltage ranges. Options for standard configurations include 3000V, 3300V, 6000V, 6600V, 10000V, and 11000V with ±5% tolerance. The voltage ranges facilitate industrial applications and are compatible with electrical infrastructure.

2. How do I choose an application protection level?

Motor protection level depends on operating environment. IP54 protection offers adequate dust and water spray protection for most industrial applications. High-risk situations may require greater protection ratings, while clean indoor installations may not.

3. What affects motor performance and efficiency?

Load, temperature, and maintenance affect motor efficiency. Size properly to maximise efficiency and prevent overloading. Bearing lubrication and cooling system cleaning keep equipment running smoothly throughout its lifespan.

Ready to Enhance Your Industrial Operations with XCMOTOR?

XCMOTOR delivers exceptional engineering excellence through our comprehensive range of high-performance industrial motors. Our experienced team provides personalized consultations to identify optimal solutions for your specific operational requirements. With advanced customization capabilities and proven reliability across diverse applications, we serve as your trusted 4000 kw motor manufacturer for critical industrial projects. Contact our technical specialists at xcmotors@163.com for detailed specifications and customized quotations.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Standard Methods for Determining Losses and Efficiency from Tests." IEC 60034-2-1:2014 Standard.

2. IEEE Power Engineering Society. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017.

3. National Electrical Manufacturers Association. "Motors and Generators Standards Publication." NEMA MG 1-2016.

4. Johnson, Michael R. "Industrial Motor Selection and Application Guidelines." Power Systems Engineering Quarterly, Vol. 45, No. 3, 2023.

5. Anderson, Sarah K. "Energy Efficiency Standards for High-Capacity Industrial Motors." Industrial Equipment Review, 2024 Edition.

6. Thompson, David L. "Maintenance Best Practices for Large Industrial Motors." Electrical Engineering Handbook, 12th Edition, 2024.