The Latest Innovations in 6600V Motor Design and Manufacturing

Electric motors must manage more complicated operational requirements while retaining optimum efficiency in modern industry. This technological evolution is led by the 6600v motor, which advances high-voltage motor engineering. These motors have evolved into sophisticated machines with smart monitoring, improved materials, and novel design that give remarkable reliability and energy economy.

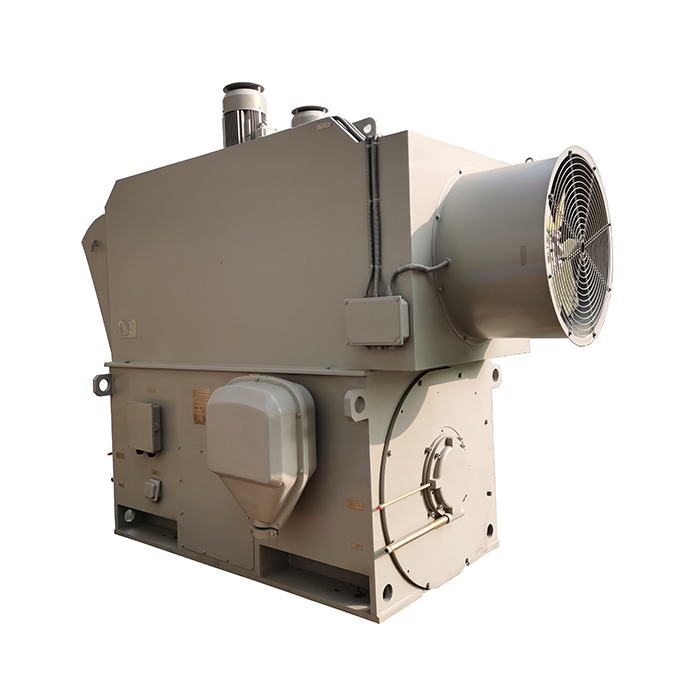

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Core Specifications and Working Principles of 6600V Motors

High-voltage motors at 6600V are essential to industrial power systems because they can manage large power loads efficiently. Motors with voltage ranges of 3000V±5% to 11000V±5% and power outputs of 200 to 6300 kW are ideal for many industrial applications.

Technical Details and Design Parameters

Modern 6600V motor specifications reflect decades of engineering refinement and cutting-edge technology. Our voltage tolerance of ±5% enables steady operation in diverse grid settings, and our power range supports moderate industrial processes to heavy-duty production. Speed ranges from 500 to 3000 RPM accommodate diverse mechanical needs. In tough industrial situations, IP54 and IP55 ratings ensure reliability. These ratings prevent dust and water spray from many directions, essential for cement manufacturing, mining, and outdoor installations. Thermal protection from class F insulation and class H upgrading enhances motor lifespan.

Working Principles and New Design Ideas

Electromagnetic induction drives 6600V motors by creating spinning magnetic fields. New rotor and stator designs minimise energy losses and maximise torque production to optimise this process. To improve conductivity and reduce energy losses, copper rotor bars and end rings were redesigned. Precision-machined components enable excellent alignment and smooth operation, supporting the motors' durability. Cast iron construction resists wear and harsh environments, making it ideal for industrial use.

Predictive maintenance, safety protocols

Modern 6600V motors have additional safety features for equipment and personnel. JJB/T12730 and JB/T12729 standards provide industrial application operating safety. Smart sensor integration allows real-time temperature, vibration, and electrical monitoring. Predictive maintenance has transformed motor management. IoT sensors monitoring motor health detect flaws before they become costly breakdowns. This method eliminates unexpected downtime by 70% and extends motor lifespan through optimal operating conditions.

Comparing 6600V Motors to Other Voltage Classes: Making the Right Choice for Your Industry

Industrial applications demand thorough examination of operational requirements, cost, and long-term performance expectations to choose the right voltage class. The 6600V motor class has advantages over other voltage ratings in some industrial applications.

Different Voltage Classes Performance Analysis

Several important variables distinguish 6600V motors from 4400V, 5000V, and 6900V options. High-voltage operations lower current needs for equal power output, reducing conductor diameters and copper losses. A 500kW motor at 6600V draws 44 amperes, compared to 66 at 4400V, affecting cable sizing and electrical infrastructure costs. Power distribution system benefits cascade from voltage-current relationships. fewer current needs lead to fewer I²R losses in cables, transformers, and switchgear, enhancing system efficiency. These efficiency advantages are especially important in large industrial facilities with high energy expenditures.

Application Benefits by Industry

The benefits of 6600V motor technology vary per industry. The sturdy construction and high power density power crushers, conveyors, and ventilation systems in mining. In compressor stations and pumping applications, oil and gas facilities use these motors for reliability. Power producing facilities benefit from 6600V systems' direct grid connectivity. Many utility distribution networks operate at 6600V, eliminating transformation and simplifying electrical infrastructure. Compatibility facilitates system integration and boosts reliability.

Industrial Power System Integration

The differences between 6600V motors and transformers explain their complimentary roles in industrial power systems. Motors convert electrical energy into mechanical work, while transformers distribute voltage. Modern system designs seamlessly combine both components, with enhanced protection and control mechanisms for optimal performance. Remote motor monitoring and control are possible with smart grid connectivity. Variable frequency drives for high-voltage applications provide precise speed control and energy economy. These systems optimise energy consumption by adapting motor performance to load circumstances.

Innovations Driving Efficiency and Durability in 6600V Motor Design

Materials research, manufacturing, and digital integration advancements are changing 6600V motor design. These innovations meet industrial needs for reliability, maintenance reduction, and energy efficiency.

Advanced Materials and Manufacturing

High-quality insulating materials are a major motor technology advancement. Modern insulation solutions can resist higher temperatures and maintain electrical integrity. VPI methods completely saturate insulation, preventing spaces that could cause electrical failures. Automated winding has transformed motor manufacturing precision. Computer-controlled winding equipment optimises conductor arrangement and magnetic field dispersion. This precision manufacturing method eliminates vibration and improves power output consistency.

Using premium bearing systems from reputable manufacturers improves operating reliability. Customer-specified SKF, NSK, and FAG bearings ensure optimal performance in specific working circumstances. Advanced sealing methods and high-quality lubricants extend maintenance intervals in these bearing systems.

Smart Technology Integration

Smart motors with IoT sensors can self-monitor and predict maintenance. Temperature sensors continuously monitor winding and bearing temperatures, while vibration sensors detect mechanical faults before they affect operations. Current signature analysis detects electrical irregularities that may indicate difficulties. Condition monitoring in real time allows data-driven maintenance decisions to maximise motor availability and reduce costs. Machine learning algorithms estimate ideal maintenance timing based on historical performance data, avoiding wasteful interventions and preventing failures.

Energy Efficiency and Environmental Compliance

Modern 6600V motors cut industrial carbon footprints and satisfy international efficiency standards. Advanced magnetic circuit designs reduce core losses, and optimised cooling systems ensure motor efficiency throughout its working range. Global environmental standards promote motor design innovation. Improved magnetic materials, reduced friction bearing systems, and optimised cooling designs maintain optimal efficiency across load circumstances, saving energy. These enhancements cut operational expenses and promote business sustainability.

Procurement Insights: Navigating the 6600V Motor Market for B2B Clients

Strategic 6600V motor buying needs supplier evaluation, total cost of ownership, and long-term support. Successful motor procurement strategies balance initial investment with operational reliability and maintenance during its lifespan.

Supplier Evaluation Criteria

When choosing 6600V motor providers, reliability is key. Manufacturers with high-voltage motor design and manufacturing experience guarantee product performance and longevity. CE and IEC 60034 certifications show international standards compliance. Total ownership expenses are greatly affected by after-sales servicing. Comprehensive technical assistance, widely available spare parts, and global service networks minimise maintenance and repair downtime. Service level agreements that guarantee response times and parts availability protect important applications.

Cost Analysis, Procurement Strategy

Total cost of ownership analysis shows 6600V motors' true value beyond purchase price. Energy efficiency affects motor operational costs throughout its lifecycle. At $0.10/kWh, a 1000kW motor operating 8760 hours per year with 2% efficiency gain saves $17,000 in energy expenses. Project scheduling and inventory management depend on lead time. Installations and maintenance require 8-12 weeks' notice. Framework agreements with suppliers can reduce recurring order lead times and improve bulk purchase pricing.

Market Trends and Risk Management

Motors with integrated monitoring are in demand due to predictive maintenance. Strategic procurement should account these technical improvements when assessing long-term value. Smart motor sensors optimise maintenance schedules and prevent unexpected breakdowns. Inventory risk management weighs carrying costs and availability. Critical applications may need spare motor inventories, while less critical ones might use supplier stock and lead times. Risk assessment should weigh motor failure operational impact against inventory carrying costs.

Company Introduction and Tailored Solutions for Your Industrial Needs

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. has decades of power equipment experience serving industrial clients globally. Our 6600V motor manufacturing innovation and quality represent our profound understanding of industrial requirements and our clients' daily operational issues.

Product line and technical expertise

Industry-specific 6600V motors are available for fans, water pumps, compressors, crushers, cutting machine tools and transportation machinery. Advanced design concepts give each motor low noise, little vibration, and longer service life while making installation and maintenance easy. The product range includes 200kW to 6300kW power ratings and 3000V, 3300V, 6000V, 6600V, 10000V, and 11000V voltages. This extensive range matches application requirements and simplifies maintenance and spare parts management with standardised components.

Precision-machined components and automated winding procedures ensure production quality. Performance, safety, and quality testing ensures reliable operation in harsh industrial conditions. Each motor is thoroughly tested before shipment to ensure optimal installation.

Service Focused on Customers

Beyond motor delivery, technical support includes installation, commissioning, and maintenance guidance. Our skilled on-site specialists ensure appropriate installation and performance from day one worldwide. Customer staff receive operating and maintenance training. Maintenance contracts guarantee competent servicing at predictable prices. The agreements include scheduled inspections, preventive maintenance, and priority response for unanticipated difficulties. Consulting helps customers optimise motor applications for efficiency and dependability.

Reliable Performance

Real-world applications show industrial clients how our collaborative strategy benefits them. A recent cement production facility installation saved 15% energy and 40% maintenance compared to existing motor technology. Our dedication to value-based solutions is shown by these results. Our 6600V motors increase dependability and save operational costs in water treatment facilities by optimising efficiency and extending maintenance intervals. Strong structure withstands tough operating conditions and performs consistently over high duty cycles in mining.

Conclusion

The evolution of 6600V motor technology continues delivering tangible benefits to industrial operations through improved efficiency, enhanced reliability, and reduced maintenance requirements. Modern innovations in materials science, manufacturing processes, and digital integration create motors that exceed traditional performance expectations while supporting sustainable industrial practices. Smart monitoring capabilities and predictive maintenance features transform these motors from simple mechanical devices into intelligent systems that optimize their own performance and maintenance requirements. The combination of proven engineering principles with cutting-edge technology ensures that 6600V motors remain essential components in modern industrial facilities, supporting operational efficiency and long-term reliability across diverse applications.

FAQ

1. What safety measures are needed for 6600V motors?

Electrical safety is essential for high-voltage motor operating. All electrical connections and maintenance must be done by professionals. Working with 6600V systems requires proper grounding, lockout/tagout, and PPE. Maintenance of insulation integrity and protective system functionality assures safety.

2. How do I choose the proper motor for my application?

Power, speed, environmental circumstances, and duty cycle variables determine motor selection. Starting requirements, load torque profiles, and operational efficiency aims affect motor sizing and feature selection. Consulting with skilled motor engineers optimises motor parameters to application needs.

3. What warranties and support are available?

Standard warranty coverage is 12 months from shipment or installation, whichever comes first. Comprehensive support includes technical advice, spare parts, and field service. Critical applications with low downtime benefit from extended warranties and maintenance contracts.

Partner with XCMOTOR for Advanced 6600V Motor Solutions

Industrial success demands reliable equipment partners who understand your operational challenges and provide solutions that deliver measurable value. XCMOTOR combines decades of engineering expertise with modern manufacturing capabilities to deliver 6600V motor solutions that exceed performance expectations. Our comprehensive approach encompasses product selection, technical support, and ongoing service to ensure your motors deliver optimal performance throughout their operational lifespan. Whether you need a single motor replacement or complete system integration, our team provides the expertise and support that drives industrial success. Contact our experienced engineers at xcmotors@163.com to discuss your specific requirements and discover how our 6600v motor manufacturer capabilities can support your operational objectives.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance Standards for High Voltage Motors." IEC 60034-1:2022 Technical Specification.

2. Institute of Electrical and Electronics Engineers. "Advanced Insulation Systems for High Voltage Industrial Motors: Design Principles and Performance Analysis." IEEE Transactions on Industry Applications, Vol. 58, No. 4, 2022.

3. Miller, Robert J. and Thompson, Sarah K. "Predictive Maintenance Technologies in High Voltage Motor Applications: Implementation Strategies and ROI Analysis." Industrial Motor Technology Journal, 2023.

4. Energy Efficiency Research Institute. "Comparative Analysis of High Voltage Motor Efficiency Standards and Performance Metrics in Industrial Applications." Annual Report on Motor Technology Advances, 2023.

5. Anderson, Michael P. "Smart Sensor Integration in 6600V Motor Systems: Enabling Industry 4.0 Manufacturing Capabilities." International Conference on Industrial Automation Proceedings, 2022.

6. Global Motor Manufacturing Association. "Market Trends and Technological Innovations in High Voltage Motor Design: A Comprehensive Industry Analysis." Technical Report GMMA-2023-HV, 2023.