Strategic sourcing of medium voltage motors represents a critical decision point for regional power grid operators seeking to balance operational efficiency with cost management. The 3.3 kV Motor has emerged as a practical solution for power generation facilities, distribution substations, and industrial applications that demand reliable performance under demanding conditions. These motors provide the necessary power output while maintaining manageable voltage levels that reduce infrastructure complexity and operational risks. Understanding the nuances of procurement, installation, and maintenance becomes essential for engineering teams responsible for grid reliability and procurement professionals tasked with optimizing capital expenditure across multi-year infrastructure projects.

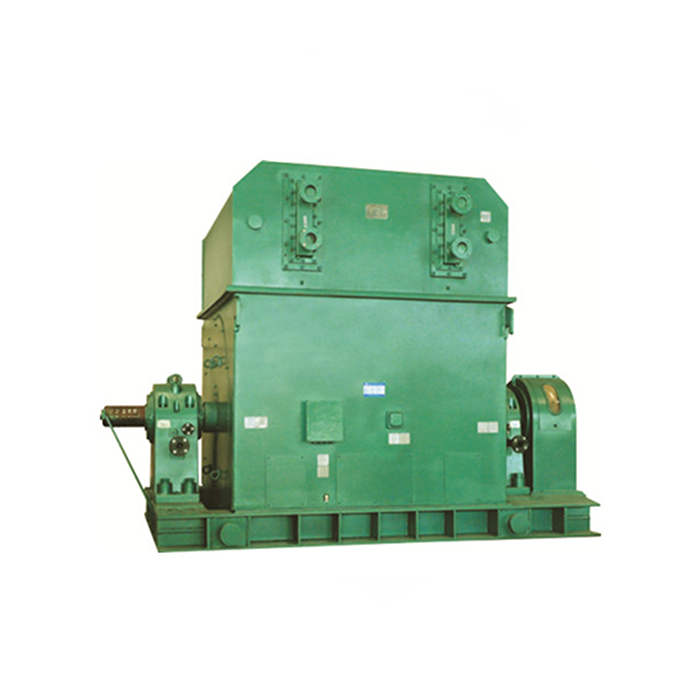

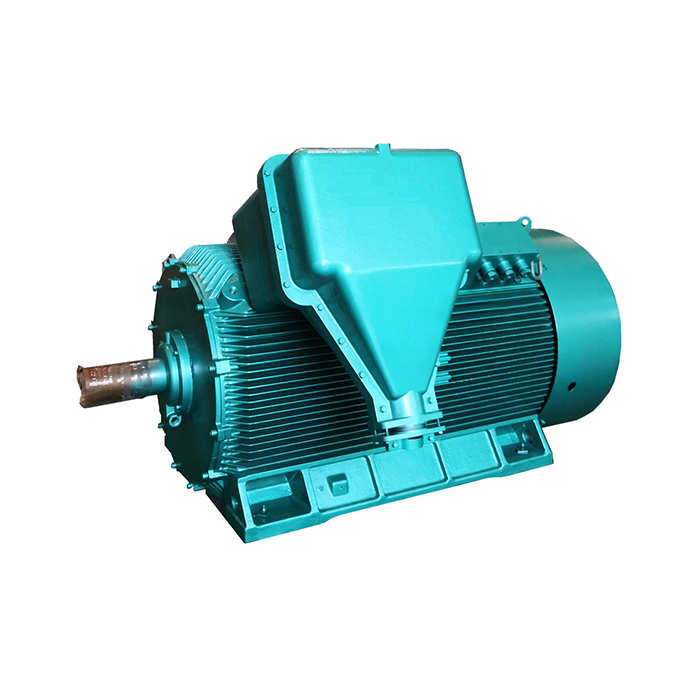

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Medium Voltage Motors for Power Grid Applications

Medium voltage motors serve as essential components in regional power grid infrastructure, bridging the gap between low voltage equipment and high voltage transmission systems. Their role extends beyond simple mechanical conversion to encompass grid stability, load management, and operational flexibility that modern power systems require.

Basics of Medium Voltage Motor Operation and Types

Medium voltage motors operate on electromagnetic principles that convert electrical energy into mechanical motion through magnetic field interactions. The 3.3 kV Motor utilizes three-phase alternating current to create rotating magnetic fields within the stator, inducing current in the rotor, and generating torque. This fundamental operation supports various motor configurations, including asynchronous and synchronous designs.

Asynchronous engines, also known as acceptance engines, are the most common type in control lattice applications due to their strong development and negligible support requirements. These units ordinarily accomplish effectiveness evaluations between 92% and 96%, depending on stack conditions and plan details. Synchronous engines offer exact speed control and control figure redress capabilities, making them important for applications requiring correct timing or receptive control support.

Service life desires for legitimately kept up medium voltage engines run from 15 to 25 years in commonplace lattice applications. Components impacting life span incorporate working environment, stack characteristics, support hones, and introductory construct quality. Engines planned for ceaseless operation cycles frequently consolidate upgraded cover frameworks and cooling components to withstand delayed operation beneath shifting stack conditions.

Key Advantages in Grid Infrastructure Applications

The execution of medium voltage engines in control network foundation gives a few operational and financial benefits that legitimize their determination over elective arrangements. Vitality effectiveness speaks to a essential advantage, with cutting edge plans accomplishing proficiency levels that diminish operational costs and natural affect over the motor's benefit life.

Here are the core advantages these motors bring to grid applications:

- Compact structure and lightweight design: Reduces installation complexity and structural support requirements compared to higher voltage alternatives

- Low noise operation: Enables installation in urban environments and sensitive locations without significant acoustic disturbance

- Minimal vibration: Supports precision applications and reduces wear on connected equipment and mounting structures

- Extended service life: Provides reliable operation over decades with proper maintenance, reducing replacement frequency and associated costs

- Simplified installation: Requires less specialized equipment and safety measures compared to higher voltage motor installations

These advantages collectively contribute to reduced total cost of ownership while maintaining the performance standards required for critical grid infrastructure applications.

Evaluating and Comparing Motors for Procurement

Effective procurement requires comprehensive evaluation across technical specifications, supplier capabilities, and long-term support considerations. The comparison process extends beyond initial purchase price to encompass operational efficiency, maintenance requirements, and supplier reliability factors that impact project success.

Comparison with Alternative Voltage Motors

Voltage selection significantly impacts system design, operational characteristics, and infrastructure requirements. The 3.3 kV Motor offers distinct advantages when compared to both lower and higher voltage alternatives in specific application scenarios.

When compared to 6.6 kV engines, 3.3 kV units require less complex cover frameworks and security gear, lessening both capital and operational costs. The lower voltage also rearranges upkeep methods and diminishes the specialized training requirements for operations faculty. Be that as it may, 6.6 kV engines may offer advantages in applications requiring higher control thickness or longer cable runs where voltage drop becomes significant.

Compared to standard medium-voltage engines, medium-voltage units give prevalent effectiveness at higher control levels and decrease current necessities, empowering smaller cable sizes and diminished electrical losses. This gets to be especially profitable in applications surpassing 500 kW, where moo voltage arrangements ended up illogical due to current impediments and cable size requirements.

Torque characteristic,s moreover, change between voltage classes, with medium voltage engines regularly giving more steady torque conveyance over changing stack conditions. This solidness demonstrates the importance of network applications where stack varieties are common and solid execution is basic for system stability.

Brand and Supplier Benchmarking

Supplier assessment requires appraisal of specialized capabilities, fabricating quality, conveyance execution, and progressing back administrations. Built-up producers regularly offer comprehensive product lines with demonstrated track records in control framework applications, whereas specialized providers may give customized solutions for interesting requirements.

Key components for provider appraisal incorporate quality certifications such as ISO 9001 and IEC compliance, which illustrate commitment to fabrication guidelines and product quality. Fabricating capabilities, counting custom setup alternatives and testing offices, show the supplier's capacity to meet particular extend necessities and give satisfactory quality assurance.

After-sales benefit capabilities speak to another basic assessment measure, enveloping save parts accessibility, specialized back responsiveness, and field benefit capabilities. Providers with built up benefit systems can give quicker reaction times and more comprehensive bolster all through the motor's operational life.

Strategic Sourcing Process for Medium Voltage Motors

Successful sourcing requires systematic evaluation of technical requirements, supplier capabilities, and commercial considerations. The process begins with clear definition of operational needs and extends through supplier qualification, negotiation, and contract execution.

Identifying Procurement Requirements and Budget Constraints

Effective sourcing starts with clearly defined technical requirements, grid integration needs, and project timelines. Budget planning should emphasize total cost of ownership, including efficiency, installation, maintenance, and delivery reliability.

Supplier Selection and Qualification

Supplier qualification evaluates technical capability, quality certifications, delivery capacity, and financial stability. Beyond price, assessment should include lead times, customization ability, warranty terms, and long-term service support to reduce project risk.

Negotiating Terms and Ensuring Warranty Coverage

Contract negotiations focus on delivery schedules, performance guarantees, warranty scope, and service agreements. Collaborative, long-term supplier relationships improve reliability, enable tailored solutions, and often secure better support and pricing.

Installation, Maintenance, and Troubleshooting Best Practices

Proper installation and ongoing maintenance significantly impact motor performance, reliability, and service life. Understanding these requirements enables better procurement decisions and supports operational planning throughout the motor's lifecycle.

Proper Installation and Wiring Guidance

Correct installation focuses on mounting, alignment, ventilation, and electrical connections. Accurate alignment reduces vibration and bearing wear, while proper cabling, insulation handling, and protective coordination ensure safe, reliable medium-voltage operation.

Routine Maintenance Tips to Maximize Lifespan

Preventive maintenance includes scheduled lubrication, vibration and thermal monitoring, and periodic electrical testing. Condition trending and insulation checks detect early faults, reduce unplanned downtime, and extend motor service life.

XCMOTOR Expertise and Product Portfolio

Shaanxi Qihe Xicheng Electromechanical Gear Co., Ltd. brings broad involvement in control hardware arrangements to territorial framework applications around the world. Our commitment to giving tall vitality proficiency, moo vitality utilization, and steady control hardware adjusts with the requesting prerequisites of present day control framework projects.

Company Introduction and Product Services

Our medium voltage motor portfolio encompasses power ranges from 160 kW to 1600 kW with voltage configurations including 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, and 11000V±5%. These products serve diverse applications including fans, water pumps, compressors, crushers, cutting machine tools, and transportation machinery across various industrial sectors.

Product specifications include an IP54 protection rating for reliable operation in challenging environments, frequency ratings of 50 Hz, speed ranges from 500 to 3000 RPM, and IC411 cooling methods. All products comply with JB/T10444-2004 standards, ensuring quality and reliability for critical applications.

Customization capabilities enable adaptation to specific project requirements, including alternative bearing specifications using trusted brands like SKF, NSK, and FAG according to customer preferences. This flexibility ensures optimal performance and maintenance compatibility with existing infrastructure.

Our service commitment includes prompt resolution of pre-sales inquiries, technical support during installation and commissioning, and ongoing after-sales service throughout the equipment lifecycle. Fast delivery capabilities and 30-day return policies provide additional assurance for procurement decisions.

Conclusion

Strategic sourcing of medium voltage motors requires comprehensive evaluation of technical requirements, supplier capabilities, and long-term operational considerations. The 3.3 kV Motor provides an effective balance between performance and operational simplicity for regional power grid applications. Success depends on understanding application requirements, evaluating supplier qualifications, and establishing relationships that support long-term operational goals. Proper installation and maintenance practices maximize equipment value and ensure reliable service throughout extended operational periods.

Frequently Asked Questions

1. What factors most influence the lifespan of a medium voltage motor?

Operating environment, stack characteristics, upkeep hours, and introductory construct quality speak to the essential components influencing engine life expectancy. Legitimate establishment, standard support, and fitting application determination can expand benefit life to 20+ years in normal lattice applications.

2. How should procurement teams decide between 3.3 kV and higher voltage motors for industrial applications?

The choice depends on control prerequisites, cable run lengths, security considerations, and support capabilities. Lower voltages, for the most par,t offer streamlined establishment and support, whereas higher voltages may be fundamental for high-power applications or long cable runs where voltage drop becomes significant.

3. What are typical lead times and shipping considerations for large motor orders?

Standard arrangements ordinarily require 8-12 weeks for conveyance, whereas custom determinations may amplify lead times. Expansive orders or specialized necessities can require extra time. Arranging ought to account for shipping coordinations, customs procedures for universal orders, and coordination with construction schedules.

Partner with XCMOTOR for Your Motor Solutions

XCMOTOR stands ready to support your power infrastructure projects with comprehensive 3.3 kV Motor solutions tailored to regional grid requirements. Our expertise encompasses technical consultation, customized configurations, and ongoing support throughout your equipment lifecycle. As a trusted 3.3 kV Motor supplier, we combine quality manufacturing with responsive service to meet demanding project timelines and performance specifications. Contact our technical team to discuss your specific requirements and discover how our motor solutions can enhance your grid infrastructure reliability. Reach out today to contact us at xcmotors@163.com for detailed product specifications and technical support.

References

1. IEEE Guide for AC Motor Protection - IEEE Std C37.96-2012, Institute of Electrical and Electronics Engineers, 2012.

2. International Electrotechnical Commission, "Rotating electrical machines - Part 1: Rating and performance," IEC 60034-1:2017.

3. National Electrical Manufacturers Association, "Motors and Generators - MG 1-2016," NEMA Standards Publication, 2016.

4. Electric Power Research Institute, "Motor Efficiency Guide - Applications for Industrial and Commercial Facilities," EPRI Technical Report 1022686, 2011.

5. American Society of Heating, Refrigerating and Air-Conditioning Engineers, "Energy Efficient Design of Medium Voltage Motor Systems," ASHRAE Journal, Vol. 60, No. 3, 2018.

6. International Council on Large Electric Systems, "Guide for Application of Medium Voltage Motors in Power Systems," CIGRE Technical Brochure 792, 2020.