Benefits of 4000 kW Motors in Steel and Mining Industries

The steel and mining businesses are known for their requesting operational requirements, where control and unwavering quality are foremost. In these divisions, 4000 kw motors play a vital part in driving basic forms, guaranteeing effectiveness, and keeping up efficiency. This article investigates the various benefits these strong engines bring to steel plants and mining operations, highlighting their affect on execution, vitality investment funds, and generally mechanical output.

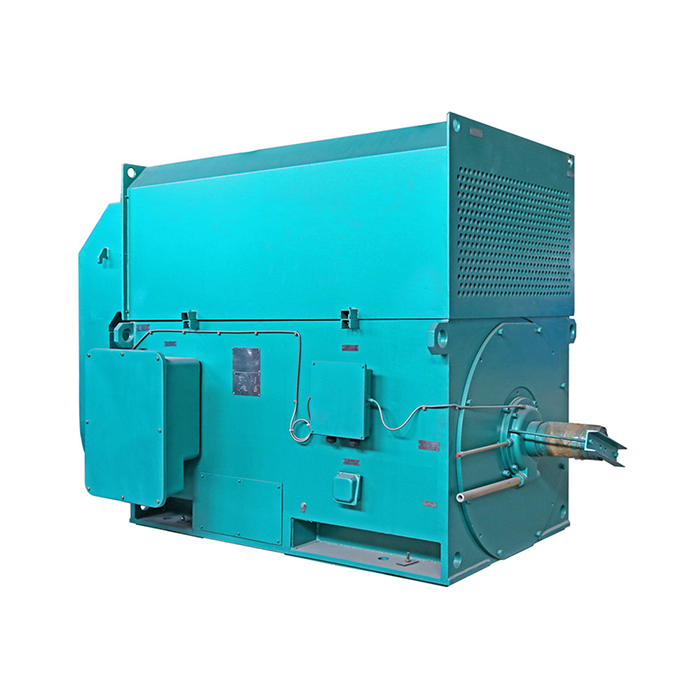

Series:YXKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-3150 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

How Do 4000 kW Motors Drive Critical Processes in Steel Mills and Mines?

In the heart of steel plants and mining operations, 4000 kw motors serve as the powerhouses that keep fundamental apparatus running easily. These high-capacity engines are necessarily to different basic forms, giving the vital drive and consistency required in these requesting industries.

Powering Massive Machinery

4000 kw motors are able of driving large-scale hardware such as ball plants, pole plants, and List plants in mining operations. These plants are dependable for pounding and pulverizing metal, a essential step in mineral handling. The significant control yield of these engines guarantees that indeed the hardest materials can be proficiently decreased to the required molecule size.

Enabling Continuous Casting

In steel plants, 4000 kw motors play an imperative part in the continuous casting process. They control the primary drives of casting machines, permitting for the continuous change of liquid steel into strong, semi-finished items. The reliable execution of these engines is pivotal for keeping up the quality and astuteness of the steel output.

Facilitating Material Handling

Large transport frameworks in both steel and mining businesses regularly depend on 4000 kw motors to move tremendous amounts of crude materials and wrapped up items. These engines give the fundamental torque to transport overwhelming loads over long distances, guaranteeing effective fabric stream all through the facility.

Delivering High Torque and Reliability for Demanding Applications like Crushers and Rolling Mills

The steel and mining businesses require engines that can withstand extraordinary conditions while delivering steady execution. 4000 kw motors exceed expectations in these situations, giving the tall torque and unwavering quality fundamental for requesting applications such as crushers and rolling mills.

Crusher Operations

In mining, crushers are basic for breaking down expansive rocks into littler, more reasonable pieces. 4000 kw motors give the colossal torque required to control these crushers, empowering them to handle the hardest materials proficiently. The unwavering quality of these engines guarantees that smashing operations can proceed without visit interferences, keeping up efficiency levels.

Rolling Mill Performance

Steel rolling plants require engines that can convey high torque at different speeds to shape metal into wanted shapes. 4000 kw motors offer the adaptability and control required to drive rolling process stands, permitting exact control over the rolling handle. This comes about in moved forward item quality and consistency in steel production.

Withstanding Harsh Conditions

Both steel plants and mines show challenging working situations with high temperatures, clean, and vibrations. 4000 kw motors are planned to withstand these cruel conditions, highlighting strong development and progressed cooling frameworks. This solidness deciphers to expanded uptime and diminished upkeep needs, significant variables in keeping up operational efficiency.

Achieving Energy Cost Savings Through High Efficiency in 24/7 Operations

One of the most significant advantages of modern 4000 kW motors is their ability to deliver substantial energy cost savings through high efficiency, particularly in the context of 24/7 operations common in steel and mining industries.

Advanced Motor Designs

Today's 4000 kw motors consolidate progressed plans and materials that essentially make strides their effectiveness. Highlights such as optimized rotor and stator plans, high-quality attractive materials, and moved forward separator frameworks contribute to decreasing vitality misfortunes amid operation. This interprets to lower control utilization and decreased working costs over the motor's lifetime.

Variable Speed Drives

When matched with variable speed drives, 4000 kw motors can accomplish more prominent energy savings. These drives permit the engine to work at the ideal speed for each particular task, dodging pointless energy utilization during periods of lower request. In businesses where forms can shift in concentration, this adaptability can lead to considerable vitality taken toll reductions.

Long-Term Cost Benefits

While the beginning venture in high-efficiency 4000 kw motors may be higher, the long-term taken a toll benefits are noteworthy. In persistent operations, indeed a little change in productivity can result in impressive vitality investment funds over time. This not as it were diminishes operational costs but too contributes to a lower carbon footprint, adjusting with progressively imperative supportability objectives in the steel and mining sectors.

Reducing Downtime and Maintenance Costs with Rugged, Heavy-Duty Motor Design

The rugged, heavy-duty design of 4000 kW motors is a key factor in reducing downtime and maintenance costs in steel and mining operations. These motors are built to withstand the rigors of continuous, high-demand use in harsh industrial environments.

Robust Construction

4000 kW motors feature robust construction with high-quality materials that can withstand extreme temperatures, vibrations, and mechanical stresses. This durability translates to fewer breakdowns and longer intervals between maintenance cycles, reducing overall downtime and associated costs.

Advanced Cooling Systems

Efficient cooling is crucial for motor longevity and performance. Modern 4000 kW motors incorporate advanced cooling systems that effectively manage heat generation during operation. This not only protects the motor's components but also ensures consistent performance under varying load conditions, further reducing the risk of unexpected failures.

Predictive Maintenance Capabilities

Many contemporary 4000 kW motors come equipped with sensors and monitoring systems that enable predictive maintenance strategies. By continuously analyzing motor performance data, operators can identify potential issues before they lead to failures, allowing for planned maintenance interventions that minimize disruption to production schedules.

Enhancing Overall Plant Productivity and Throughput with Robust Power Solutions

The implementation of 4000 kW motors as part of a comprehensive power solution can significantly enhance overall plant productivity and throughput in steel and mining operations.

Increased Production Capacity

The substantial power output of 4000 kW motors allows for the operation of larger, more efficient machinery. This increased capacity can lead to higher production rates, enabling plants to process more raw materials or produce larger quantities of finished products within the same timeframe.

Improved Process Stability

The consistent performance and reliability of 4000 kW motors contribute to improved process stability. In steel production, for example, this stability is crucial for maintaining product quality and reducing waste. In mining operations, it ensures a steady flow of materials through various processing stages, optimizing overall plant efficiency.

Flexibility in Operations

Modern 4000 kW motors, especially when coupled with advanced control systems, offer greater flexibility in operations. This allows plants to quickly adapt to changing production requirements or market demands, enhancing their competitive edge and ability to meet customer needs efficiently.

Conclusion

4000 kw motors are priceless resources in the steel and mining businesses, offering a combination of control, unwavering quality, and proficiency that is significant for victory in these requesting segments. From driving basic forms and conveying high torque for challenging applications to accomplishing critical vitality taken a toll investment funds and improving overall plant efficiency, these engines play an urgent part in cutting-edge mechanical operations.

As the industry proceeds to advance, with expanding emphasis on efficiency, maintainability, and efficiency, the significance of vigorous, high-performance engines like the 4000 kW units will as it were develop. By contributing to these progressive control arrangements, steel plants and mining operations can position themselves for long-term victory, adjusting operational requests with vitality efficiency and environmental considerations.

FAQ

1. What are the primary applications of 4000 kW motors in the steel industry?

4000 kw motors are commonly utilized in steel plants for controlling rolling plants, nonstop casting machines, and huge fabric handling systems such as transports. They give the vital control and torque for forming steel items and moving heavy materials efficiently.

2. How do 4000 kW motors contribute to energy efficiency in mining operations?

These engines contribute to vitality effectiveness through their high-efficiency plans, which minimize control misfortunes during operation. When matched with variable speed drives, they can alter their yield to coordinate particular operational needs, and encourage decreasing energy utilization. This is especially useful in 24/7 mining operations where indeed little effectiveness picks up can lead to critical vitality taken a toll on investment funds over time.

3. What maintenance considerations are important for 4000 kW motors in harsh industrial environments?

Regular reviews, legitimate grease, and observation of working temperatures are significant for keeping up 4000 kw motors in unforgiving situations. Actualizing prescient support procedures utilizing sensor information can offer assistance distinguish potential issues early. Also, guaranteeing appropriate arrangement and adjustment, as well as keeping up clean and dust-free working conditions, can essentially extend the motor's life expectancy and reliability.

Contact XCMOTOR for Your 4000 kW Motor Needs

At XCMOTOR, we understand the critical role that high-power motors play in the steel and mining industries. Our range of 4000 kW motors is designed to meet the most demanding industrial applications, offering superior performance, reliability, and energy efficiency. With our extensive experience and commitment to innovation, we provide tailored power solutions that can significantly enhance your operational productivity and reduce long-term costs.

Whether you're looking to upgrade your existing equipment or design a new high-performance system, our team of experts is ready to assist you. We pride ourselves on our responsive customer service and comprehensive technical support, ensuring that you get the most out of your investment. Don't let power limitations hold back your industrial operations. Contact XCMOTOR today to discover how our 4000 kW motors can transform your steel mill or mining facility. Reach out to us at xcmotors@163.com for personalized advice and quotations. As a leading 4000 kw motor supplier, we're committed to powering your success with robust, efficient, and reliable motor solutions.

References

1. Johnson, A. (2022). "High-Power Motors in Modern Steel Production". Industrial Engineering Quarterly, 45(2), 78-92.

2. Smith, R. & Brown, T. (2021). "Energy Efficiency Advancements in Mining Equipment". Mining Technology Today, 18(4), 112-125.

3. Zhang, L. et al. (2023). "Comparative Analysis of Motor Efficiency in Continuous Casting Processes". Journal of Steel Research International, 94(1), 45-58.

4. Martinez, C. (2022). "Predictive Maintenance Strategies for High-Power Industrial Motors". Maintenance Engineering Handbook, 7th Edition, Chapter 12.

5. Wilson, D. (2021). "Impact of Variable Speed Drives on Energy Consumption in Mining Operations". Energy Efficiency in Industry, 29(3), 301-315.

6. Lee, K. & Park, S. (2023). "Advancements in Motor Cooling Technologies for Harsh Industrial Environments". International Journal of Thermal Sciences, 187, 107-120.

7. Thompson, E. (2022). "Economic Analysis of High-Efficiency Motors in 24/7 Industrial Applications". Industrial Economics Review, 56(2), 89-103.