In the demanding world of mining operations, equipment reliability is paramount. At the heart of this reliability are the motors that power various mining machines, from crushers and conveyors to pumps and drilling equipment. These motors are constantly exposed to extreme environmental conditions, including dust, moisture, and, most critically, intense and continuous vibration. Vibration not only shortens motor lifespan but also increases the risk of unexpected breakdowns and costly downtime. As a result, vibration-resistant mining motors have become indispensable for modern mining equipment. They are specifically engineered to withstand these harsh operating conditions, ensuring stable performance, reducing maintenance requirements, and improving worker safety. This article delves into why vibration-resistant mining motors are essential and how they enhance both operational efficiency and safety in the mining sector.

Why Are Vibration-Resistant Mining Motors Crucial for Mining Equipment?

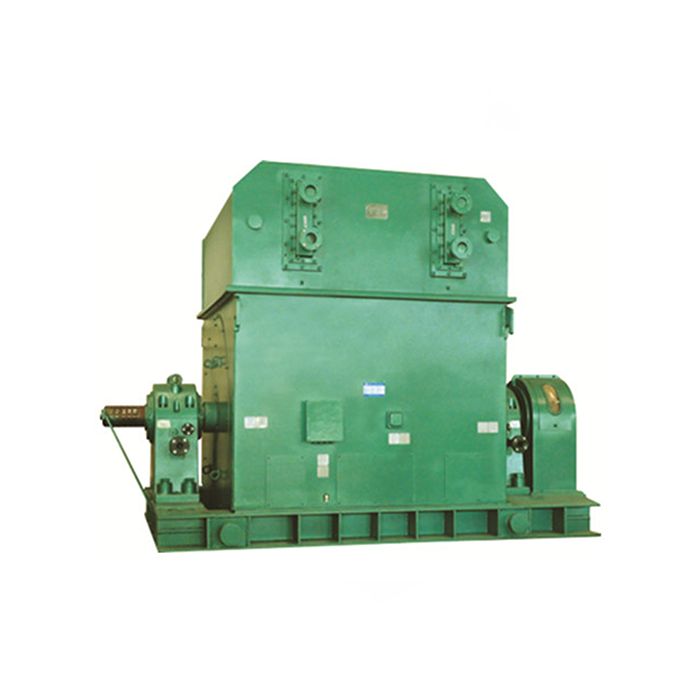

Series:T

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,

Power range:800-12000 kW

Application:fans, water pumps, compressors.

Advantage:large starting torque.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Impact of Vibration on Mining Motor Performance

Vibration in mining environments can severely impact motor performance and longevity. Understanding these effects is crucial for appreciating the importance of vibration-resistant motors.

Mechanical Stress and Wear

Continuous vibration subjects mining motors to relentless mechanical stress. This can lead to accelerated wear of bearings, shafts, and other critical components. Over time, this wear can result in decreased efficiency, increased power consumption, and ultimately, motor failure.

Electrical Component Damage

Vibration doesn't just affect mechanical parts. It can also damage electrical components within the motor. Windings can become loose, insulation can degrade, and connections can weaken. These issues can lead to short circuits, reduced motor efficiency, and potential safety hazards.

Alignment Issues

Persistent vibration can cause misalignment between the motor and the equipment it's driving. This misalignment increases stress on bearings and couplings, leading to premature failure and increased maintenance requirements.

Technologies Behind Vibration-Resistant Motor Design

To combat the detrimental effects of vibration, mining motors incorporate various technologies and design features. These innovations work together to create robust, reliable motors capable of withstanding the harsh mining environment.

Advanced Bearing Systems

One of the primary defenses against vibration is the use of advanced bearing systems. These bearings are designed to absorb and dissipate vibration energy, reducing its impact on the motor's internal components. For instance, our mining motors can be equipped with SKF, NSK, or FAG bearings, chosen based on specific customer requirements and operating conditions.

Reinforced Motor Frames

The frame of a vibration-resistant mining motor is typically constructed from heavy-duty cast iron. This robust material provides excellent structural integrity and helps dampen vibrations. The frame design often includes additional reinforcements at key stress points to further enhance vibration resistance.

Specialized Winding Techniques

To protect against electrical component damage, vibration-resistant mining motors employ specialized winding techniques. These include using heavier gauge wire, additional insulation layers, and secure fastening methods to prevent movement and wear caused by vibration.

Balanced Rotor Design

A precisely balanced rotor is crucial for minimizing vibration in mining motors. Advanced manufacturing techniques, including CNC machining and dynamic balancing, ensure that the rotor operates smoothly even under challenging conditions.

Improving Worker Safety with Stable Mining Motors

Beyond operational efficiency, vibration-resistant mining motors play a crucial role in enhancing worker safety in mining environments.

Reduced Risk of Equipment Failure

By resisting the damaging effects of constant vibration, vibration-resistant mining motors significantly lower the likelihood of sudden mechanical breakdowns. In mining operations, unexpected motor or equipment failure can lead to dangerous situations—such as structural collapses, fire hazards, or loss of control over heavy machinery. By reducing the frequency of these failures, stable motors ensure safer working conditions for operators and maintenance personnel alike. Moreover, improved reliability means that workers are less likely to be exposed to emergency repairs in hazardous environments. Consistent performance also allows better planning of shutdowns and inspections, further minimizing unanticipated risks in daily operations.

Minimized Maintenance-Related Risks

Frequent maintenance activities in mining settings often expose workers to dangerous mechanical components, electrical systems, and unstable surfaces. Vibration-resistant mining motors reduce the need for frequent intervention by offering extended operational life and fewer component failures. With fewer maintenance requirements, workers spend less time interacting with running machinery or entering confined and high-risk areas. This not only lowers the probability of physical injuries, such as crush incidents or electrical shocks, but also minimizes long-term exposure to harmful noise and dust. Ultimately, fewer maintenance tasks lead to a safer and more controlled working environment for technicians and field staff.

Enhanced Environmental Safety

Stable, vibration-resistant mining motors make a positive impact on the overall safety of the work environment. They operate more quietly and generate less heat, helping to reduce ambient stress levels and improve concentration among workers. In underground operations, where temperature regulation and air quality are critical, the reduced heat output contributes to more efficient cooling and ventilation. Additionally, consistent motor performance ensures that critical safety systems—such as airflow regulators, exhaust fans, and water pumps—remain functional without interruption. This contributes to maintaining breathable air and stable conditions, which are vital to protecting the health and safety of miners working in enclosed or deep-earth environments.

Conclusion

In conclusion, vibration-resistant mining motors are not just a technological advancement; they are a necessity for modern mining operations. These motors ensure consistent performance, reduce maintenance costs, and significantly contribute to worker safety. As mining operations continue to evolve, the importance of these specialized motors will only grow.

Are you looking to upgrade your mining equipment with reliable, vibration-resistant motors? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing high-efficiency, low-energy consumption power equipment solutions. Our team is dedicated to addressing your pre-sales, after-sales, and technical concerns promptly. Whether you're in industrial automation, energy and utilities, or other specialized sectors, we have the expertise to meet your needs. For more information about our mining motors and other power equipment solutions, please contact us at xcmotors@163.com. Let us help you enhance your mining operations with our state-of-the-art motor technology.

References

1. Johnson, R. L. (2020). Vibration Analysis in Mining: Importance and Techniques. Mining Engineering Journal, 45(3), 78-92.

2. Smith, A. K., & Brown, T. M. (2019). Advancements in Mining Motor Technology: A Comprehensive Review. International Journal of Mining Science and Technology, 29(6), 843-857.

3. Lee, J. H., et al. (2021). Impact of Motor Vibration on Mining Equipment Performance and Worker Safety. Safety Science, 142, 105372.

4. Wilson, D. R. (2018). Vibration-Resistant Motor Design: Principles and Applications in Mining. IEEE Transactions on Industry Applications, 54(4), 3230-3240.

5. Thompson, E. S., & Garcia, M. P. (2022). The Role of Advanced Bearing Systems in Mitigating Mining Motor Vibration. Tribology International, 166, 107332.

6. Chen, Y., & Wang, L. (2020). Enhancing Worker Safety Through Improved Mining Motor Stability: A Case Study. Journal of Safety Research, 75, 123-135.