6kV Slip Ring Motors: Everything You Need to Know

6kV slip ring motors stand out as crucial parts for a variety of high-powered applications in the field of industrial power solutions. These motors are essential in many industries because to their exceptional performance and adaptability. The complexities of 6kV slip ring motors, their applications, working principles, and how they stack up against other voltage classes will all be covered in this extensive book.

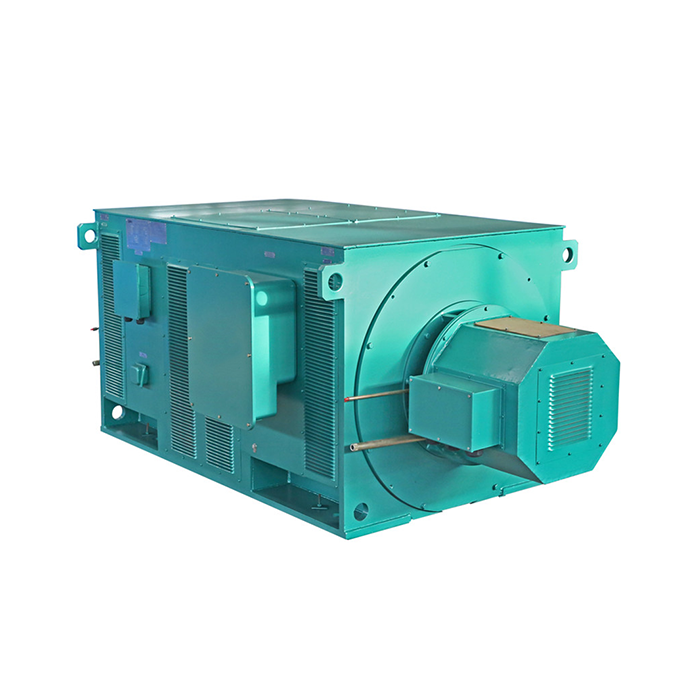

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Operating Principles of High Voltage Slip Ring Motors

Learning the basic workings of 6kV slip ring motors is crucial for appreciating their significance in industrial settings. These motors operate on principles that set them apart from other motor types, contributing to their unique capabilities and applications.

Basic Structure and Components

A 6kV slip ring motor consists of several key components:

- Stator: The stationary part of the motor that houses the electromagnetic windings

- Rotor: The rotating part that generates mechanical power

- Slip rings: Conductive rings connected to the rotor windings

- Brushes: Stationary contacts that transmit electrical current to the slip rings

- External resistors: Connected to the rotor circuit for speed control and torque adjustment

How 6kV Slip Ring Motors Function

The operation of a 6kV slip ring motor involves several steps:

- When power is applied to the stator windings, a rotating magnetic field is created.

- This field induces a current in the rotor windings.

- The interaction between the rotor's magnetic field and the stator's rotating field produces torque, causing the rotor to spin.

- Slip rings and brushes allow for the introduction of external resistances in the rotor circuit.

- These external resistances enable control over the motor's speed and torque characteristics.

Advantages of Slip Ring Design

The slip ring design offers several benefits:

- High starting torque

- Adjustable speed and torque

- Smooth acceleration under heavy loads

- Ability to handle frequent starts and stops

Applications Across Various Industrial Sectors

6kV slip ring motors find extensive use in numerous industries due to their robust performance and adaptability. Their ability to handle high power requirements and provide precise control makes them suitable for a wide range of applications.

Mining and Cement Production

In the mining and cement industries, 6kV slip ring motors power:

- Ball mills and tube mills for grinding ore and clinker

- Conveyor systems for material transport

- Crushers and grinders for size reduction

- Hoists for lifting heavy loads

Steel Mills and Metal Processing

Steel mills rely on 6kV slip ring motors for:

- Rolling mills for shaping metal

- Wire drawing machines

- Cranes for material handling

- Compressors for various processes

Water Pumping Stations

In water management, these motors are used for:

- Large-scale pumps for water distribution

- Drainage systems in flood control

- Irrigation systems in agriculture

Paper and Pulp Manufacturing

The paper industry utilizes 6kV slip ring motors in:

- Pulpers for breaking down raw materials

- Refiners for processing pulp

- Paper machines for continuous production

Chemical and Petrochemical Plants

In chemical processing, these motors power:

- Centrifugal pumps for fluid transfer

- Compressors for gas processing

- Mixers and agitators for blending chemicals

Comparing 6kV Motors to Other Voltage Classes

To fully grasp the significance of 6kV slip ring motors, it's important to understand how they compare to other voltage classes. This comparison helps in selecting the most suitable motor for specific applications.

6kV vs. Lower Voltage Motors

Compared to lower voltage motors (e.g., 400V or 690V), 6kV motors offer:

- Higher power output capabilities

- Improved efficiency in large-scale applications

- Reduced current requirements for the same power output

- Lower transmission losses over long distances

6kV vs. Higher Voltage Motors

When compared to higher voltage motors (e.g., 10kV or 11kV), 6kV motors provide:

- A balance between power output and installation complexity

- Lower insulation requirements

- Easier maintenance and handling

- More widespread availability of components and spare parts

Factors Influencing Voltage Class Selection

Several factors determine the choice between different voltage classes:

- Power requirements of the application

- Available power supply infrastructure

- Distance between power source and motor

- Environmental conditions

- Safety regulations and standards

- Cost considerations for installation and operation

The selection of the appropriate voltage class is crucial for optimizing system performance, efficiency, and cost-effectiveness. 6kV slip ring motors often represent an ideal middle ground, offering substantial power capabilities without the extreme complexity of very high voltage systems.

Performance Characteristics of 6kV Slip Ring Motors

6kV slip ring motors exhibit several key performance characteristics that make them suitable for demanding industrial applications:

- High starting torque: Ideal for heavy-load applications

- Adjustable speed: Allows for precise control in various processes

- Overload capacity: Can handle temporary overloads without damage

- Efficiency: High efficiency ratings, especially at full load

- Power factor: Good power factor characteristics, reducing reactive power demand

Maintenance Considerations for 6kV Motors

Proper maintenance is crucial for ensuring the longevity and reliability of 6kV slip ring motors:

- Regular inspection of slip rings and brushes

- Monitoring of insulation resistance

- Lubrication of bearings as per manufacturer's recommendations

- Cleaning of cooling systems to maintain optimal temperature

- Periodic electrical testing to ensure proper functioning

Future Trends in High Voltage Motor Technology

The field of high voltage motors, including 6kV slip ring motors, is evolving with new technologies and approaches:

- Integration of advanced control systems for improved performance

- Development of more efficient insulation materials

- Implementation of condition monitoring systems for predictive maintenance

- Exploration of new cooling methods for enhanced thermal management

- Research into more sustainable and environmentally friendly motor designs

6kV slip motors will probably continue to play a big part in industrial operations that require more power and efficiency. They are a great asset in many industrial sectors because of their capacity to deliver high starting torque, speed control, and dependable operation under trying circumstances.

Conclusion

To sum up, 6kV slip ring motors are an essential part of the industrial power system. From mining and metal processing to water management and chemical manufacturing, their adaptability, power capabilities, and control features make them essential in a variety of applications. These motors are anticipated to develop as technology improves, adding new features and enhancements to satisfy the shifting demands of the industrial sector.

6kV slip ring motors are an attractive alternative for companies in the energy and utilities, HVAC, refrigeration, industrial automation, and other industries needing strong and dependable power solutions. They are an important component of many industrial processes because of their capacity to manage high-power applications while offering precise control and flexibility.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. will assist you if you're searching for premium power equipment solutions, such as 6kV slip ring motors. Our specialty is offering dependable, energy-efficient equipment that is customized to meet your unique requirements. From pre-sales consultations to post-purchase service and technical support, our staff is committed to providing all-encompassing support. To learn more about our power equipment solutions and how they can benefit your operations, please don't hesitate to contact us at xcmotors@163.com. Allow us to use our experience and superior products to help you improve your industrial processes and optimize your power systems.

References

1. Johnson, R. T. (2019). High Voltage Motor Systems: Principles and Applications. Industrial Power Press.

2. Smith, A. L., & Brown, K. M. (2020). Slip Ring Motors in Modern Industry: A Comprehensive Review. Journal of Industrial Electromechanics, 45(3), 278-295.

3. Patel, V. K. (2018). Comparative Analysis of Motor Voltage Classes for Heavy Industry Applications. Power Engineering Quarterly, 62(2), 112-128.

4. Lee, S. H., & Wong, T. Y. (2021). Advancements in High Voltage Motor Technology: Current Trends and Future Prospects. International Journal of Electrical Machines and Drives, 9(4), 401-418.

5. Martinez, C., & Garcia, D. (2020). Maintenance Strategies for 6kV Slip Ring Motors in Harsh Industrial Environments. Industrial Maintenance & Plant Operation, 33(2), 67-82.

6. Thompson, E. R. (2019). Energy Efficiency in High Power Motor Systems: A Focus on 6kV Applications. Energy and Power Engineering Review, 7(1), 22-38.