Sourcing the right inverter duty induction motor for your HVAC chiller system can make or break your operational efficiency. These specialized motors work seamlessly with variable frequency drives to deliver precise speed control, reduce energy consumption by up to 30%, and extend equipment lifespan significantly. When properly matched to your chiller requirements, an inverter duty induction motor transforms your HVAC system from a basic cooling unit into an intelligent, adaptable powerhouse that responds to real-time demand fluctuations.

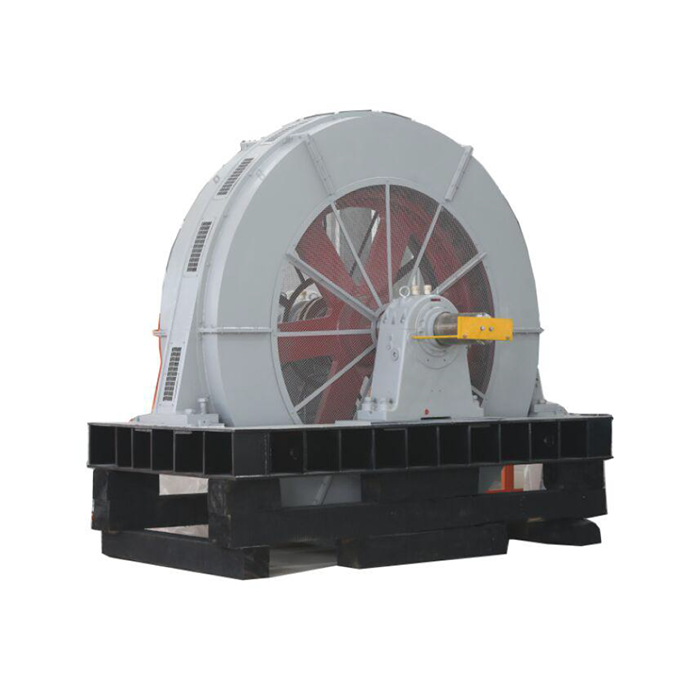

Series:YVFE3

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Introduction

Modern HVAC chillers demand motors that can handle the complexity of variable speed operation while maintaining peak efficiency across diverse load conditions. The selection of an appropriate inverter duty induction motor directly influences your system's energy consumption, maintenance costs, and overall reliability. Procurement managers and engineers face mounting pressure to balance initial investment costs with long-term operational savings, making motor selection a critical strategic decision.

The stakes are especially high in mechanical applications where chiller downtime translates to generation misfortunes and compromised natural control. Standard engines frequently battle beneath the demanding conditions of VFD operation, leading to untimely disappointments and startling substitution costs. Understanding the specialized details and sourcing considerations for inverter obligation engines engages decision-makers to construct strong HVAC frameworks that provide reliable execution while minimizing add up to fetched of ownership.

Understanding Inverter Duty Induction Motors

Inverter duty induction motors represent a specialized category of electrical machines engineered specifically for variable frequency drive applications. These motors incorporate enhanced insulation systems rated for Class F (155°C) operation, enabling them to withstand the voltage spikes and harmonics generated by electronic speed controls. The reinforced winding structure and improved bearing protection make them ideally suited for the demanding operating conditions found in modern HVAC chillers.

Enhanced Construction Features

Inverter duty induction motors feature reinforced windings, Class F insulation, optimized cooling, and bearing protection, ensuring reliable performance, high efficiency, and minimized electrical stress under variable frequency drive operation in HVAC chillers.

Technical Specifications and Performance Parameters

XCMOTOR inverter duty induction motors offer 0.75–1000 kW, 5–100 Hz operation, IP55 protection, constant torque/power ranges, and low vibration, providing flexible, efficient, and reliable performance for residential and industrial HVAC chillers.

Comparing Inverter Duty Motors with Other Motor Types for HVAC Applications

Understanding the execution contrasts between engine sorts empowers educated obtainment choices that optimize both introductory costs and long-term operational productivity. Standard acceptance engines, although less costly forthright, frequently demonstrate insufficient for variable speed applications due to restricted speed ranges and warm administration challenges.

Performance Characteristics Across Motor Types

Inverter duty induction motors handle wide speed ranges and full torque at zero speed, unlike standard or capacitor start motors, enabling precise control and energy-efficient operation in modern HVAC systems.

Total Cost of Ownership Analysis

Though more expensive initially, inverter duty induction motors reduce energy use, maintenance, and downtime, recovering costs within two years while enhancing reliability and system longevity in variable-speed HVAC applications.

How to Source and Procure Inverter Duty Induction Motors for HVAC Chillers?

Effective acquisition starts with a comprehensive application examination to set up exact engine necessities. Control rating calculations must account for both steady-state and transitory working conditions, counting startup loads and crisis working scenarios. Natural components, such as encompassing temperature, humidity, and exposure to destructive substances impact security lesson necessities and fabric specifications.

Supplier Evaluation Criteria

Reliable inverter duty induction motor suppliers provide ISO 9001-certified manufacturing, robust quality control, comprehensive warranties, and technical support, ensuring long-term reliability and minimizing procurement risk for HVAC chiller applications.

Procurement Channel Strategies

Direct manufacturer relationships and online platforms balance customization, technical support, and competitive pricing for inverter duty induction motors, with global supply chains enabling efficient delivery of standard and specialized HVAC chiller solutions.

Maintenance, Troubleshooting, and Longevity Best Practices

Proactive upkeep methodologies maximize engine life expectancy whereas avoiding startling disappointments that compromise chiller operation. Customary assessment conventions center on basic wear focuses counting orientation, separator keenness, and cooling framework viability. Warm imaging studies distinguish creating issues sometimes recently they result in disappointments, empowering planned support amid planned downtime.

Preventive Maintenance Schedules

Monthly visual reviews recognize self-evident signs of weakening, such as oil spills, abnormal commotion, or intemperate vibration. Quarterly electrical estimations track separator resistance and current adjustments to identify creating electrical deficiencies. Yearly bearing grease and arrangement checks anticipate mechanical disappointments that account for the majority of engine problems.

Operating condition checking through vibration examination and warm checking gives early caution of creating issues. These prescient upkeep procedures empower upkeep planning amid arranged blackouts or maybe than crisis shutdowns that disturb building operations.

Troubleshooting Common Issues

Overheating issues regularly stem from a lack of ventilation or improper stack conditions. Confirming appropriate wind stream around the engine and checking the real stack against appraised capacity ordinarily distinguishes the root cause. Anomalous clamor regularly shows bearing wear or mechanical misalignment requiring quick attention.

Wiring deficiencies show through current awkward nature or ground blame conditions recognizable through electrical testing. Stage voltage estimations uncover supply issues that can harm engine windings if cleared out uncorrected. Customary electrical testing distinguishes these issues some time recently they cause disastrous failures.

Case Studies and Real-World Applications of Inverter Duty Motors in HVAC Chillers

Real-world implementations demonstrate the practical benefits achievable through proper motor selection and application. A recent retrofit project at a pharmaceutical manufacturing facility replaced standard motors with inverter duty units, achieving 28% energy reduction and eliminating three unplanned shutdowns that had previously disrupted production.

Energy Efficiency Improvements

The pharmaceutical facility case study revealed energy consumption dropped from 2.8 MW to 2.0 MW during peak cooling season through optimized speed control. The variable frequency drive operation enabled the chiller to match cooling output to actual demand rather than cycling on and off at fixed output levels. Annual energy cost savings exceeded $180,000, recovering the motor upgrade investment in 22 months.

Temperature control precision improved significantly, maintaining process temperatures within ±0.5°C compared to ±2.0°C with the previous fixed-speed system. This enhanced control eliminated product quality issues that had previously resulted in batch rejections.

Reliability and Maintenance Benefits

Motor-related maintenance calls decreased by 75% following the upgrade, with no bearing replacements required during the initial three years of operation. Vibration levels dropped to less than 1.5 mm/s compared to 4.2 mm/s with the original motors, indicating substantial improvement in mechanical condition.

The enhanced reliability translated to improved facility uptime and reduced maintenance costs. Emergency service calls eliminated, and planned maintenance intervals extended from six months to annual schedules. These operational improvements delivered ongoing value beyond the initial energy savings.

Company Introduction and Product & Service Information

XCMOTOR specializes in delivering comprehensive motor solutions engineered specifically for HVAC chiller applications. Our technical expertise spans application analysis, product customization, and ongoing support services designed to optimize system performance throughout the equipment lifecycle. We understand the critical role that motor selection plays in overall system efficiency and reliability.

Product Portfolio and Technical Capabilities

Our inverter duty motor portfolio covers power ranges from 0.75kW to 1000kW with multiple voltage and frequency options to match diverse application requirements. Advanced manufacturing processes including precision die-casting and automated winding ensure consistent quality and performance. Vacuum pressure impregnation provides superior insulation integrity for extended service life under demanding VFD conditions.

Quality certifications including ISO 9001:2015 and CE marking demonstrate our commitment to manufacturing excellence and international compliance. Rigorous testing at each production stage verifies performance specifications before shipment, ensuring reliable operation from initial startup.

Service and Support Infrastructure

Our specialized meeting services offer assistance to clients explore the complexities of engine determination and application optimization. Designing bolster amplifies from beginning detail improvement through establishment and commissioning help. Comprehensive guarantee scope secures your venture whereas our devoted back group gives continuous specialized assistance.

Global supply chain capabilities guarantee competitive estimating and solid conveyance plans. Our obtainment group works closely with clients to create sourcing methodologies that adjust taken a toll, quality, and conveyance prerequisites. Expanded guarantee alternatives give extra security for basic applications where downtime carries critical consequences.

Conclusion

Sourcing the appropriate inverter duty induction motor for HVAC chiller applications requires balancing technical performance requirements with commercial considerations. The enhanced construction and operational capabilities of these specialized motors deliver measurable benefits in energy efficiency, reliability, and maintenance costs that justify the initial investment. Proper supplier selection and ongoing maintenance practices ensure optimal performance throughout the motor's service life, maximizing return on investment while supporting reliable chiller operation.

FAQ

1. What makes inverter duty motors essential for HVAC chiller applications?

Inverter obligation engines give the exact speed control and operational adaptability required for present day energy-efficient chiller frameworks. Their improved development withstands the electrical and warm stresses of variable recurrence drive operation whereas conveying steady execution over wide speed ranges.

2. How do I determine the correct motor sizing for my chiller application?

Motor sizing requires analysis of both steady-state and transient load conditions. Consider the chiller's power requirements across its operating range, including startup loads and emergency operating scenarios. Environmental conditions and duty cycle also influence sizing decisions.

3. What warranty and support options should I expect from suppliers?

Comprehensive warranty coverage should protect against manufacturing defects and premature failures. Technical support availability ensures rapid resolution of application questions and troubleshooting assistance. Extended warranty options may be available for critical applications.

4. Can inverter duty motors operate in harsh environmental conditions?

These motors accommodate challenging environments through enhanced protection ratings and specialized construction materials. IP55 protection handles most industrial environments, while higher protection classes are available for extreme conditions.

Partner with XCMOTOR for Superior Inverter Duty Induction Motor Solutions

XCMOTOR delivers proven inverter duty induction motor solutions that transform HVAC chiller performance through enhanced efficiency and reliability. Our experienced engineering team provides comprehensive technical consultation and customized product configurations to meet your specific application requirements. With competitive pricing, rapid delivery, and outstanding after-sales support, we serve as your trusted inverter duty induction motor supplier for critical HVAC projects.

Contact our technical specialists at xcmotors@163.com to discuss your chiller motor requirements and explore how our advanced motor solutions can optimize your system performance.

References

1. Industrial Motor Selection Guide for HVAC Applications, American Society of Heating, Refrigerating and Air-Conditioning Engineers, 2023.

2. Variable Frequency Drive Motor Specifications and Performance Standards, International Electrotechnical Commission Technical Report 60034-25, 2022.

3. Energy Efficiency in Commercial HVAC Systems: Motor Selection and Optimization Strategies, Energy Engineering Journal, Volume 45, Issue 3, 2023.

4. Maintenance Best Practices for Inverter Duty Motors in Industrial Applications, Electrical Apparatus Service Association Technical Manual, 2023.

5. Cost-Benefit Analysis of Premium Efficiency Motors in HVAC Chiller Systems, Building Services Engineering Research and Technology Journal, 2022.

6. Reliability Engineering for Motor-Driven HVAC Equipment: Failure Analysis and Prevention Strategies, Mechanical Engineering Handbook, 4th Edition, 2023.