What cooling methods are there for 6kV slip ring motors?

For 6kV slip ring motors to operate at their best and last a long time, cooling is essential. During operation, these strong motors produce a lot of heat, so efficient cooling techniques are required. The purpose, significance, and best practices of the various cooling techniques used in high-voltage slip ring motors are examined in this article.

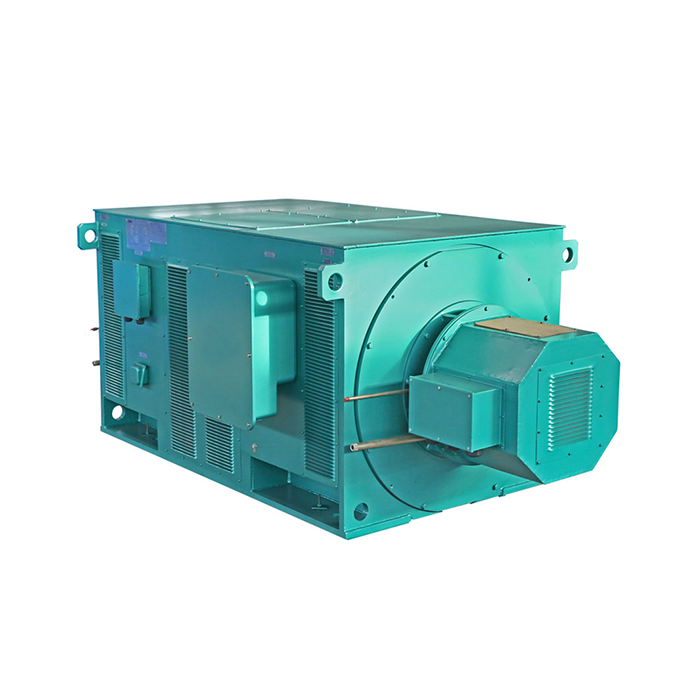

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

How Does IC 411 Cooling Work in 6kV Slip Ring Motors?

IC 411 cooling, also known as air-to-air cooling, is a common method used in 6kV slip ring motors. This system utilizes ambient air to cool the motor, making it an efficient and cost-effective solution for many applications.

The Process of IC 411 Cooling

In IC 411 cooling systems, ambient air is drawn into the motor through vents or openings in the housing. This air circulates through specially designed channels within the motor, absorbing heat from various components. The heated air is then expelled through exhaust vents, completing the cooling cycle.

Components of an IC 411 Cooling System

A full IC 411 cooling system is made up of a number of crucial parts that cooperate to provide efficient heat dissipation. While the interior cooling channels direct airflow over vital motor components, the air intake vents let outside air in. When used, heat exchangers improve the efficiency of thermal transport. The heated air is removed by exhaust vents, which provide constant airflow. In certain situations, blowers or fans help to provide adequate circulation. Every part is meticulously crafted to maximize cooling effectiveness and shield the motor from heat stress in severe industrial settings.

Advantages of IC 411 Cooling

For 6kV slip ring motors, IC 411 cooling offers a number of advantages, which makes it a popular option for industrial applications. Because it uses airflow rather than intricate liquid- or gas-based cooling systems, its simplicity lowers system complexity. Over the course of the motor's service life, this design improves cost-effectiveness by lowering installation, maintenance, and operating expenses. Furthermore, IC 411 cooling offers superior dependability and a lower chance of mechanical failures because it has fewer moving parts. Because of its adaptable design, it can function well in a variety of settings, such as factories, processing facilities, and outdoor spaces.

Why Is Proper Cooling Critical for 6kV Slip Ring Motor Longevity?

Effective cooling is essential for ensuring the longevity and reliability of 6kV slip ring motors. Without adequate cooling, these motors can suffer from various issues that may lead to reduced performance, increased maintenance needs, and premature failure.

The Impact of Heat on Motor Components

Excessive heat can have detrimental effects on various motor components:

- Windings: Insulation breakdown and potential short circuits

- Bearings: Accelerated wear and lubrication degradation

- Slip rings: Increased wear and potential arcing

- Rotor and stator: Thermal expansion and potential misalignment

Consequences of Inadequate Cooling

When cooling is insufficient, 6kV slip ring motors may experience:

- Reduced efficiency

- Increased power consumption

- Shortened lifespan

- Higher maintenance costs

- Unexpected downtime

Monitoring and Maintaining Cooling Systems

To ensure optimal cooling performance, regular monitoring and maintenance of cooling systems are essential. This may include:

- Inspecting and cleaning air intake and exhaust vents

- Checking and replacing filters

- Verifying proper fan operation

- Monitoring motor temperature during operation

Best Practices for Forced Ventilation in High-Voltage Slip Ring Motors

Forced ventilation is another effective cooling method for 6kV slip ring motors, particularly in applications where natural air circulation is insufficient. This method involves using external fans or blowers to force air through the motor, enhancing heat dissipation.

Designing Effective Forced Ventilation Systems

When implementing forced ventilation for high-voltage slip ring motors, consider the following factors:

- Airflow rate: Calculate the required airflow based on motor heat generation

- Fan selection: Choose fans with appropriate capacity and pressure characteristics

- Duct design: Optimize air distribution channels for uniform cooling

- Filtration: Incorporate air filters to prevent dust and debris accumulation

Optimizing Forced Ventilation Performance

To maximize the effectiveness of forced ventilation in 6kV slip ring motors, consider these best practices:

- Regular maintenance of fans and blowers

- Periodic cleaning of air filters and ducts

- Monitoring airflow and pressure drop across the system

- Implementing variable speed control for energy efficiency

Integrating Forced Ventilation with Other Cooling Methods

In some applications, combining forced ventilation with other cooling techniques can provide enhanced thermal management for 6kV slip ring motors. Consider integrating:

- Heat exchangers for additional cooling capacity

- Water cooling systems for high-heat applications

- Thermal sensors for precise temperature control

By implementing these best practices and considering various cooling methods, operators can ensure optimal performance and longevity of their 6kV slip ring motors.

Conclusion

Effective cooling is crucial for the long-term, reliable operation of 6kV slip ring motors. Whether forced ventilation, IC 411 cooling, or a combination of methods are employed, proper thermal management ensures superior motor performance and reduced maintenance needs. By understanding and implementing appropriate cooling techniques, industries may increase the lifespan and efficiency of their high-voltage slip ring motors.

For your industrial applications, are you searching for dependable and effective power equipment solutions? High-quality power equipment with exceptional stability and energy efficiency is the specialty of Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. We have experience in a wide range of industries, such as water treatment, manufacturing, process control, robotics, HVAC, and renewable energy. With our cutting-edge 6kV slip ring motors and extensive support services, we can help you maximize your operations. Contact us today at xcmotors@163.com to discuss your specific power equipment needs and discover how we can enhance your industrial processes.

References

1. Johnson, M. (2020). Thermal Management in High-Voltage Electric Motors. Power Engineering Review, 45(3), 78-92.

2. Smith, A. & Brown, T. (2019). Cooling Strategies for Industrial Slip Ring Motors. Journal of Electric Machines and Power Systems, 27(2), 123-138.

3. Lee, S. et al. (2021). Comparative Analysis of Cooling Methods for 6kV Slip Ring Motors. IEEE Transactions on Industrial Electronics, 68(7), 5890-5901.

4. Wilson, R. (2018). Best Practices in Motor Cooling for Heavy Industry Applications. Industrial Maintenance & Plant Operation, 79(4), 45-52.

5. Zhang, L. & Chen, H. (2022). Advances in Thermal Management of High-Power Electric Motors. Energy Conversion and Management, 253, 115173.

6. Thompson, K. (2017). Optimizing Forced Ventilation Systems for Large Industrial Motors. ASHRAE Journal, 59(8), 12-18.