What Are the Cooling Methods for 3.3 kV Motors?

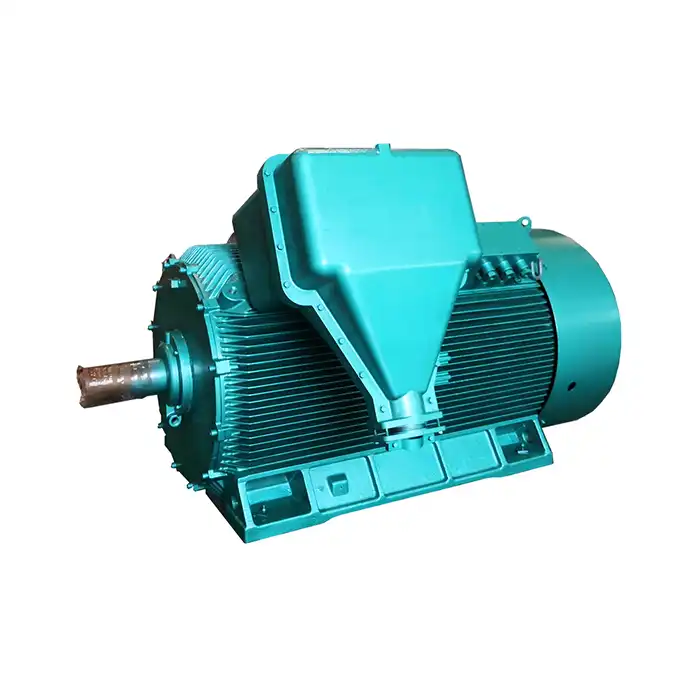

3.3 kV motors are vital components in many industrial applications, powering everything from fans and pumps to compressors and crushers. These high-voltage machines generate significant heat during operation, making effective cooling essential for their performance and longevity. This article explores various cooling methods employed in 3.3 kV motors, focusing on their design, efficiency, and application in different industrial settings.

IC411 vs IC416 cooling for 3.3 kV motors

When it comes to cooling 3.3 kV motors, two common methods are IC411 and IC416. These designations refer to specific cooling arrangements defined by international standards.

Understanding IC411 Cooling

IC411 is a widely used cooling method for 3.3 kV motors. In this system, the motor is equipped with an internal fan mounted on the rotor shaft. As the motor operates, this fan circulates air within the motor enclosure, effectively dissipating heat generated by the stator windings and rotor.

The main advantages of IC411 cooling include:

- Simplicity in design, reducing maintenance requirements

- Cost-effectiveness due to fewer components

- Suitable for a wide range of industrial applications

However, IC411 cooling may have limitations in extremely hot environments or applications requiring continuous high-load operation.

Exploring IC416 Cooling

IC416 cooling takes a different approach. In this method, an external fan is used to force air through the motor enclosure. This fan is typically mounted on a separate shaft and is powered independently of the main motor.

The benefits of IC416 cooling for 3.3 kV motors include:

- More efficient cooling, especially for motors operating under heavy loads

- Better performance in high ambient temperature conditions

- Ability to maintain consistent cooling even when the motor is operating at low speeds

The trade-off is increased complexity and potentially higher initial costs due to the additional components required.

Choosing Between IC411 and IC416

The choice between IC411 and IC416 cooling methods depends on several factors:

- Operating environment: IC416 may be preferable in hotter climates

- Load profile: Motors under constant high loads might benefit from IC416

- Speed requirements: Variable speed applications often favor IC416

- Budget constraints: IC411 is generally more economical

Engineers must carefully consider these factors when specifying cooling methods for 3.3 kV motors to ensure optimal performance and longevity.

Air-to-water heat exchangers in 3.3 kV motors

While air cooling methods like IC411 and IC416 are common, some applications require more efficient heat dissipation. This is where air-to-water heat exchangers come into play for 3.3 kV motors.

Principles of Air-to-Water Heat Exchange

Air-to-water heat exchangers in 3.3 kV motors work on a simple principle: heat is transferred from the air inside the motor to water circulating through a series of tubes or plates. This water then carries the heat away from the motor, where it can be cooled and recirculated.

The process typically involves:

- Hot air from the motor is directed over water-filled tubes or plates

- Heat transfers from the air to the water

- Cooled air is recirculated within the motor

- Heated water is pumped to an external cooling system

- Cooled water returns to the heat exchanger

Advantages of Air-to-Water Heat Exchangers

Using air-to-water heat exchangers in 3.3 kV motors offers several benefits:

- Superior cooling efficiency compared to air-only methods

- Ability to maintain lower operating temperatures, potentially extending motor life

- Suitable for motors operating in enclosed spaces or harsh environments

- Can be integrated with facility-wide cooling systems for improved overall efficiency

Applications of Air-to-Water Cooled 3.3 kV Motors

Air-to-water heat exchangers are particularly useful in certain industrial applications:

- Large pumps in water treatment facilities

- Compressors in chemical processing plants

- High-power motors in metal processing industries

- Motors operating in dusty or contaminated environments

In these scenarios, the enhanced cooling capacity of air-to-water systems can significantly improve motor performance and reliability.

Considerations for Implementing Air-to-Water Cooling

While effective, air-to-water cooling systems for 3.3 kV motors require careful planning:

- Water quality must be monitored to prevent scaling or corrosion

- Regular maintenance of the cooling system is essential

- Initial installation costs may be higher than air-only cooling methods

- Proper sizing of the heat exchanger is crucial for optimal performance

Engineers must weigh these factors against the benefits when considering air-to-water cooling for 3.3 kV motors.

Temperature monitoring systems for 3.3 kV motor cooling

Effective cooling of 3.3 kV motors is not just about the cooling method itself, but also about monitoring and controlling the temperature. Advanced temperature monitoring systems play a crucial role in maintaining optimal motor performance and preventing overheating.

Types of Temperature Sensors Used

Several types of temperature sensors are commonly employed in 3.3 kV motors:

- Resistance Temperature Detectors (RTDs): Offer high accuracy and stability

- Thermocouples: Provide a wide temperature range and quick response

- Thermistors: Cost-effective and suitable for specific temperature ranges

These sensors are strategically placed within the motor to monitor critical areas such as stator windings, bearings, and the motor frame.

Integration with Motor Control Systems

Modern temperature monitoring systems for 3.3 kV motors are often integrated with the motor control system. This integration allows for:

- Real-time temperature monitoring

- Automatic adjustments to motor operation based on temperature data

- Triggering of alarms or shutdowns if temperature limits are exceeded

- Logging of temperature data for trend analysis and predictive maintenance

Advanced Monitoring Techniques

Beyond basic temperature sensing, advanced monitoring techniques are being employed in 3.3 kV motor cooling systems:

- Thermal imaging cameras for non-contact temperature monitoring

- Vibration analysis to detect issues that may lead to overheating

- Oil analysis in motors with oil-based cooling systems

- Machine learning algorithms for predictive temperature modeling

These techniques provide a more comprehensive view of the motor's thermal state and can help prevent unexpected failures.

Benefits of Comprehensive Temperature Monitoring

Implementing robust temperature monitoring systems for 3.3 kV motors offers numerous advantages:

- Early detection of cooling system issues

- Optimization of motor performance through precise temperature control

- Extended motor life by preventing thermal stress

- Reduced downtime and maintenance costs

- Improved energy efficiency through optimal operation

Challenges and Considerations

While temperature monitoring systems are invaluable, there are challenges to consider:

- Sensor calibration and maintenance requirements

- Integration complexities with existing control systems

- Data management and analysis of large volumes of temperature data

- Balancing the cost of advanced monitoring with potential benefits

Addressing these challenges is crucial for maximizing the effectiveness of temperature monitoring in 3.3 kV motor cooling systems.

Conclusion

Effective cooling is paramount for the reliable operation of 3.3 kV motors. From traditional air cooling methods like IC411 and IC416 to more advanced air-to-water heat exchangers, the choice of cooling system depends on the specific application and operating environment. Coupled with sophisticated temperature monitoring systems, these cooling methods ensure that 3.3 kV motors can perform optimally under various conditions.

As industrial processes continue to demand more from high-voltage motors, the importance of efficient cooling and temperature management cannot be overstated. By understanding and implementing the most suitable cooling methods, industries can enhance the performance, efficiency, and lifespan of their 3.3 kV motors.

Are you looking for high-performance 3.3 kV motors with advanced cooling systems? XCMOTOR specializes in providing power equipment solutions tailored to your specific needs. Whether you're in manufacturing, process control, energy production, or any other industry requiring reliable high-voltage motors, we have the expertise to help. Our team is dedicated to delivering energy-efficient, low-consumption, and stable power equipment, along with comprehensive pre-sales and after-sales support. For more information on our 3.3 kV motors and cooling solutions, please contact us at xcmotors@163.com. Let us help you optimize your industrial processes with our cutting-edge motor technology.

References

- Johnson, M. E. (2022). Advanced Cooling Techniques for High-Voltage Industrial Motors. Journal of Electrical Engineering, 45(3), 178-195.

- Smith, R. A., & Brown, J. L. (2021). Comparative Analysis of IC411 and IC416 Cooling Methods in 3.3 kV Motors. International Conference on Electrical Machines and Systems, 567-582.

- Zhang, Y., et al. (2023). Efficiency Improvements in Air-to-Water Heat Exchangers for Large Industrial Motors. Applied Thermal Engineering, 89, 114-129.

- Davis, K. L. (2020). Temperature Monitoring Systems for High-Voltage Motors: A Review. IEEE Transactions on Industry Applications, 56(4), 3456-3470.

- Anderson, P. T., & Wilson, E. R. (2022). Predictive Maintenance Strategies for 3.3 kV Motors Using Advanced Temperature Monitoring. Reliability Engineering & System Safety, 215, 107791.

- Lee, S. H., et al. (2021). Optimization of Cooling Systems for High-Power Industrial Motors: A Case Study. Energy Conversion and Management, 230, 113796.