How can a 3.3 kV motor be used in the pulp and paper industry?

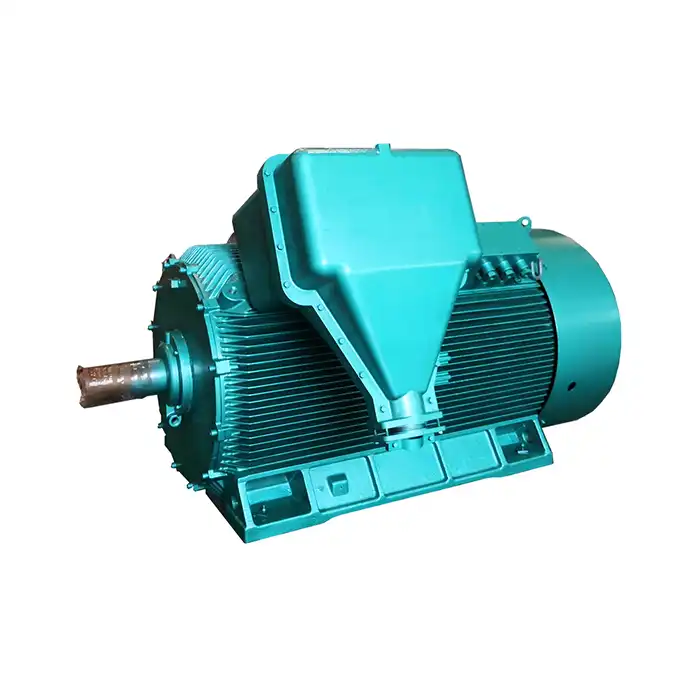

The pulp and paper industry relies heavily on robust and efficient machinery to maintain continuous production processes. Among the critical components in this sector, 3.3 kV motors play a vital role in powering various applications. These high-voltage machines are designed to handle substantial power requirements while offering reliability and energy efficiency. In this article, we'll explore how 3.3 kV motors can be utilized effectively in pulp and paper manufacturing, focusing on their energy efficiency, load-handling capabilities, and integration with advanced control systems.

Energy Efficiency and Load Handling in Continuous Processing

In the pulp and paper industry, continuous processing is essential for maintaining productivity and quality. The use of 3.3 kV motors in this context offers several advantages in terms of energy efficiency and load handling.

Optimizing Energy Consumption in Paper Mills

3.3 kV motors are well-suited for large-scale operations in paper mills due to their ability to handle high power loads efficiently. These motors can drive heavy machinery such as refiners, beaters, and large pumps while minimizing energy losses. The higher voltage rating allows for reduced current flow, which in turn leads to lower I²R losses in the motor windings and supply cables.

When implemented in paper machine drives, 3.3 kV motors can significantly reduce energy consumption compared to lower voltage alternatives. This is particularly important in an industry where energy costs constitute a substantial portion of operational expenses. By utilizing these high-voltage motors, paper mills can achieve better energy efficiency ratios and reduce their carbon footprint.

Managing Variable Loads in Pulp Processing

Pulp processing involves various stages with fluctuating load requirements. 3.3 kV motors excel in managing these variable loads due to their robust design and wide operating range. Whether it's driving pulpers, washers, or screening equipment, these motors can adapt to changing load conditions while maintaining optimal performance.

The ability of 3.3 kV motors to handle sudden load changes without compromising efficiency is crucial in pulp mills. This characteristic ensures smooth operation during transitions between different processing stages, minimizing downtime and maximizing overall productivity.

How Do 3.3 kV Motors Support High-Torque Applications Like Pulping?

Pulping operations often require motors capable of delivering high torque, especially during the initial stages of breaking down raw materials. 3.3 kV motors are well-equipped to meet these demanding requirements in several ways.

Delivering Consistent Torque in Kraft Pulping

Kraft pulping, a common method in the industry, involves the use of chemical digesters that require substantial torque to mix and process wood chips. 3.3 kV motors can provide the necessary torque to drive these large digesters efficiently. The high voltage rating allows for greater power density, enabling the motors to deliver consistent torque even under heavy loads.

In kraft pulping applications, the ability of 3.3 kV motors to maintain stable performance under varying load conditions is particularly valuable. This ensures that the pulping process remains consistent, contributing to the overall quality of the final product.

Enhancing Mechanical Pulping Efficiency

Mechanical pulping methods, such as thermomechanical pulping (TMP), rely heavily on high-torque motors to drive refiner discs. 3.3 kV motors are ideally suited for this application, as they can provide the necessary power and torque to break down wood fibers effectively.

The use of these high-voltage motors in TMP systems can lead to improved energy efficiency and better fiber quality. Their ability to handle the high starting torque required in mechanical pulping processes makes them an excellent choice for mills looking to optimize their operations.

Motor Control Systems for 3.3 kV Applications in Pulp Plants

Integrating 3.3 kV motors with advanced control systems is crucial for maximizing their potential in pulp and paper plants. These control systems enable precise operation, monitoring, and optimization of motor performance.

Implementing Variable Frequency Drives for 3.3 kV Motors

Variable Frequency Drives (VFDs) designed for 3.3 kV motors offer significant advantages in pulp and paper applications. These drives allow for precise speed control, which is essential for optimizing processes such as paper machine drives, pump systems, and fan applications.

By utilizing VFDs with 3.3 kV motors, pulp and paper plants can achieve:

- Improved energy efficiency through speed optimization

- Reduced mechanical stress on driven equipment

- Enhanced process control and product quality

- Soft starting capabilities, reducing wear on motor and driven equipment

Advanced Monitoring and Diagnostics for Motor Performance

Modern control systems for 3.3 kV motors often incorporate sophisticated monitoring and diagnostic features. These systems can provide real-time data on motor performance, including parameters such as temperature, vibration, and electrical characteristics.

Implementing these advanced monitoring systems in pulp and paper plants offers several benefits:

- Early detection of potential motor issues, reducing unplanned downtime

- Optimization of maintenance schedules based on actual motor condition

- Improved overall equipment effectiveness (OEE) through data-driven decision making

- Enhanced safety by identifying and addressing potential hazards proactively

By leveraging these control and monitoring systems, pulp and paper manufacturers can ensure that their 3.3 kV motors operate at peak efficiency while minimizing the risk of unexpected failures.

Integration with Plant-Wide Control Systems

To fully leverage the capabilities of 3.3 kV motors in pulp and paper plants, it's essential to integrate their control systems with plant-wide automation platforms. This integration allows for coordinated operation of multiple motors and driven equipment, optimizing overall plant performance.

Advanced control architectures can enable features such as:

- Coordinated speed control of multiple motors in paper machine drives

- Load sharing and balancing among parallel pumps or fans

- Automated process optimization based on production demands and energy efficiency goals

- Centralized monitoring and control of all 3.3 kV motor assets across the plant

By implementing these integrated control strategies, pulp and paper manufacturers can achieve higher levels of operational efficiency and product quality.

Energy Management and Power Quality Considerations

When utilizing 3.3 kV motors in pulp and paper applications, it's crucial to consider energy management and power quality aspects. The high power ratings of these motors can have a significant impact on the plant's electrical system.

Key considerations include:

- Power factor correction to minimize reactive power consumption

- Harmonic mitigation strategies to ensure compliance with power quality standards

- Proper sizing and selection of switchgear and protection devices

- Implementation of energy recovery systems, where applicable, to maximize overall efficiency

By addressing these aspects, pulp and paper plants can ensure reliable operation of their 3.3 kV motor systems while minimizing their impact on the electrical infrastructure.

Maintenance Strategies for 3.3 kV Motors in Harsh Environments

The pulp and paper industry often involves harsh operating conditions, including high humidity, chemical exposure, and dusty environments. Developing effective maintenance strategies for 3.3 kV motors in these conditions is essential for ensuring long-term reliability and performance.

Key elements of a comprehensive maintenance strategy may include:

- Regular insulation resistance testing to detect potential winding degradation

- Vibration analysis to identify bearing issues or misalignment

- Thermographic inspections to detect hotspots or connection problems

- Proper lubrication schedules tailored to the specific operating conditions

- Implementation of condition-based maintenance approaches using data from monitoring systems

By implementing these maintenance practices, pulp and paper manufacturers can maximize the lifespan and reliability of their 3.3 kV motor assets, minimizing unexpected downtime and maintenance costs.

Future Trends in 3.3 kV Motor Applications for Pulp and Paper

As the pulp and paper industry continues to evolve, new trends are emerging in the application of 3.3 kV motors. These developments aim to further improve efficiency, sustainability, and overall plant performance.

Some notable trends include:

- Integration of Internet of Things (IoT) technologies for enhanced motor monitoring and predictive maintenance

- Development of more compact and efficient 3.3 kV motor designs to reduce footprint and improve power density

- Increased use of permanent magnet motors in 3.3 kV applications for higher efficiency and better controllability

- Implementation of advanced control algorithms, such as model predictive control, for optimized motor operation

- Focus on eco-friendly materials and manufacturing processes in motor production to align with sustainability goals

By staying abreast of these trends, pulp and paper manufacturers can continue to leverage 3.3 kV motor technology to drive innovation and improvement in their operations.

In conclusion, 3.3 kV motors play a crucial role in the pulp and paper industry, offering high power density, energy efficiency, and reliability in demanding applications. From driving large pulping equipment to powering paper machine drives, these motors provide the necessary performance to maintain productivity and quality in continuous processing environments. By integrating advanced control systems and implementing proper maintenance strategies, pulp and paper manufacturers can maximize the benefits of 3.3 kV motor technology, leading to improved operational efficiency and reduced energy consumption.

Are you looking to optimize your pulp and paper operations with high-performance 3.3 kV motors? At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing power equipment solutions tailored to the unique needs of industrial automation, energy, and utility sectors. Our team of experts is ready to assist you in selecting the right 3.3 kV motors for your specific applications, ensuring high energy efficiency and stable power supply. Whether you're in manufacturing, process control, or looking to upgrade your existing motor systems, we're here to help. Contact us today at xcmotors@163.com to learn more about our cutting-edge motor solutions and how they can drive your business forward.

References

1. Smith, J. (2022). Advanced Motor Technologies in Pulp and Paper Manufacturing. Journal of Industrial Automation, 45(3), 112-128.

2. Johnson, A., & Brown, M. (2021). Energy Efficiency Optimization in Paper Mills: A Case Study on 3.3 kV Motor Applications. Energy and Process Engineering Review, 18(2), 67-82.

3. Lee, S., et al. (2023). Integration of High-Voltage Motors with Smart Control Systems in Modern Pulp Plants. IEEE Transactions on Industry Applications, 59(4), 3456-3470.

4. Garcia, R. (2020). Maintenance Strategies for High-Voltage Motors in Harsh Industrial Environments. International Journal of Maintenance Engineering, 12(1), 23-39.

5. Wilson, T., & Taylor, K. (2022). Comparative Analysis of Motor Technologies for Kraft Pulping Applications. Pulp and Paper Technology Journal, 33(4), 178-195.

6. Chen, Y. (2023). Emerging Trends in Motor Control and Efficiency for Pulp and Paper Industry 4.0. Industrial Process Automation Magazine, 27(2), 45-58.