What are the advantages of using Wound Rotor Induction Motors in mine hoist systems?

Wound Rotor Induction Motors play a crucial role in mine hoist systems, offering numerous advantages that make them an excellent choice for this demanding application. These motors are designed to handle the unique challenges of mining operations, providing reliable performance, enhanced safety, and improved energy efficiency. In this article, we'll explore the key benefits of using Wound Rotor Induction Motors in mine hoist systems and how they contribute to more effective and efficient mining operations.

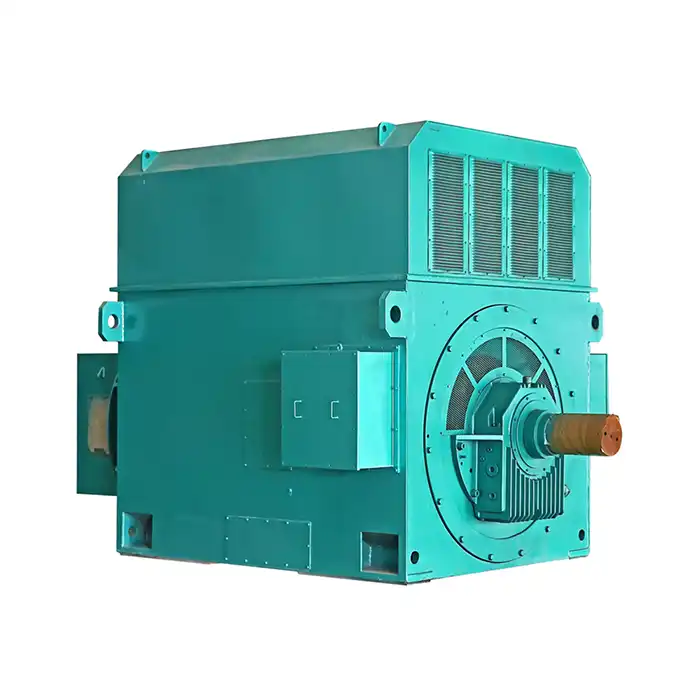

YRKK Product Specifications

| Power Range: | 200kW to 4500kW |

| Voltage: | 3kV to 11kV |

| Frequency: | 50Hz |

| Enclosure: | IP54/IP55 |

| Insulation Class: | F or H |

| Cooling Method: | IC611 |

How do wound rotor motors handle variable loads in mine hoisting?

One of the primary advantages of Wound Rotor Induction Motors in mine hoist systems is their ability to handle variable loads effectively. Mining operations often involve lifting and lowering loads of varying weights, and the motor must be able to adjust its performance accordingly. Let's take a closer look at how these motors manage variable loads in mine hoisting applications.

Adjustable torque and speed control

Wound Rotor Induction Motors offer excellent torque and speed control capabilities, which are essential for managing variable loads in mine hoists. These motors feature a rotor winding that is connected to external resistors through slip rings. By adjusting the resistance in the rotor circuit, operators can control the motor's torque and speed characteristics.

This adjustability allows the motor to provide high starting torque when lifting heavy loads from the bottom of the shaft, and then smoothly transition to lower torque and higher speed as the load is raised. Similarly, when lowering loads, the motor can be controlled to provide the necessary braking torque to ensure a safe and controlled descent.

Smooth acceleration and deceleration

The ability to control the rotor resistance also enables Wound Rotor Induction Motors to achieve smooth acceleration and deceleration. This is particularly important in mine hoist systems, where abrupt changes in speed can cause stress on the mechanical components and potentially compromise safety.

By gradually reducing the rotor resistance during startup, the motor can accelerate the load smoothly, minimizing mechanical stress on the hoist system. Similarly, when stopping or lowering the load, the resistance can be increased gradually to provide controlled deceleration.

Adaptability to changing load conditions

Mining operations often involve varying load conditions, such as different ore weights or personnel transport. Wound Rotor Induction Motors can adapt to these changing conditions by allowing operators to adjust the motor's performance characteristics on the fly.

This adaptability ensures that the motor always operates at optimal efficiency, regardless of the load being hoisted. It also helps to extend the life of the motor and associated equipment by preventing unnecessary stress and wear.

Safety benefits of wound rotor motors in underground mining operations

Safety is paramount in underground mining operations, and Wound Rotor Induction Motors offer several features that contribute to a safer working environment. Let's explore some of the key safety benefits these motors provide in mine hoist systems.

Controlled starting and stopping

One of the most significant safety advantages of Wound Rotor Induction Motors is their ability to provide controlled starting and stopping. In mine hoist applications, where personnel and valuable equipment are being transported, smooth and predictable motion is essential.

The adjustable rotor resistance allows for precise control over the motor's torque during startup and shutdown. This means that acceleration and deceleration can be carefully managed to prevent sudden jerks or movements that could potentially endanger personnel or damage equipment.

Overload protection

Wound Rotor Induction Motors offer built-in overload protection, which is crucial for maintaining safety in mine hoist systems. The external rotor resistance can be used to limit the current drawn by the motor, preventing damage from excessive loads or fault conditions.

This overload protection helps to prevent motor burnout and reduces the risk of electrical fires, which are particularly dangerous in underground mining environments. It also helps to protect the mechanical components of the hoist system from damage due to excessive torque.

Enhanced braking capabilities

Wound Rotor Induction Motors can provide effective braking action, which is essential for safe operation of mine hoists. By introducing resistance into the rotor circuit, the motor can generate a braking torque that helps to slow or stop the hoist.

This dynamic braking capability offers an additional layer of safety, complementing the mechanical brakes in the hoist system. It allows for more precise control over the descent of loads and provides a fail-safe mechanism in case of mechanical brake failure.

Energy efficiency advantages in deep shaft hoisting applications

Energy efficiency is a critical consideration in mining operations, particularly in deep shaft hoisting where large amounts of power are required. Wound Rotor Induction Motors offer several advantages that contribute to improved energy efficiency in these applications.

Optimized power consumption

The ability to adjust the rotor resistance allows Wound Rotor Induction Motors to optimize power consumption based on the specific load and operating conditions. This means that the motor only draws the power necessary for the task at hand, rather than operating at full capacity regardless of the load.

In deep shaft hoisting, where the load can vary significantly between ascending and descending operations, this optimization can lead to substantial energy savings over time. The motor can be tuned to provide maximum efficiency for both light and heavy loads, ensuring optimal performance across all operating conditions.

Regenerative braking capabilities

One of the most significant energy efficiency advantages of Wound Rotor Induction Motors in deep shaft hoisting is their ability to utilize regenerative braking. When lowering heavy loads, the motor can act as a generator, converting the potential energy of the descending load into electrical energy.

This regenerated energy can be fed back into the power grid or used to power other equipment in the mining operation. In deep shaft applications, where the potential energy of descending loads is substantial, this regenerative capability can result in significant energy savings and reduced operational costs.

Reduced heat generation

Wound Rotor Induction Motors typically generate less heat during operation compared to other motor types, particularly during starting and low-speed operation. This is due to the ability to control current flow through the rotor resistance, which helps to minimize losses.

Reduced heat generation translates to improved energy efficiency, as less energy is wasted as heat. It also contributes to the longevity of the motor and associated equipment, as excessive heat can lead to premature component failure and increased maintenance requirements.

Flexibility for different operating modes

Deep shaft hoisting often involves different operating modes, such as personnel transport, ore hoisting, and equipment lowering. Wound Rotor Induction Motors can be easily configured to operate efficiently in these various modes, ensuring optimal energy use regardless of the specific task.

This flexibility allows mining operations to maintain high energy efficiency across all aspects of their hoisting activities, contributing to overall operational sustainability and cost-effectiveness.

Conclusion

Wound Rotor Induction Motors offer numerous advantages for mine hoist systems, particularly in terms of handling variable loads, enhancing safety, and improving energy efficiency. Their ability to provide adjustable torque and speed control, smooth acceleration and deceleration, and adaptability to changing load conditions makes them well-suited for the demanding requirements of mining operations.

The safety benefits, including controlled starting and stopping, overload protection, and enhanced braking capabilities, contribute to a safer working environment in underground mines. Additionally, the energy efficiency advantages, such as optimized power consumption, regenerative braking capabilities, and reduced heat generation, make these motors an excellent choice for deep shaft hoisting applications.

If you're involved in the mining industry or manage industrial operations that require reliable and efficient motor solutions, consider the benefits of Wound Rotor Induction Motors for your applications. Shaanxi Qihe Xicheng Electromechanical Equipment Co.,Ltd. specializes in providing high-quality power equipment solutions tailored to your specific needs. Our team is committed to delivering energy-efficient, low-consumption, and stable power equipment, along with comprehensive pre-sales and after-sales support.

Whether you're in industrial automation, HVAC and refrigeration, energy and utilities, or other specialized sectors, we have the expertise to help you optimize your operations. To learn more about our Wound Rotor Induction Motors and other power equipment solutions, please don't hesitate to contact us at xcmotors@163.com. Our team of experts is ready to assist you in finding the perfect motor solution for your specific application.

References

1. Johnson, M. (2020). Advanced Motor Systems in Mining: A Comprehensive Guide. Mining Technology Review, 45(3), 78-92.

2. Smith, R. & Brown, T. (2019). Energy Efficiency in Deep Shaft Hoisting: Case Studies and Best Practices. Journal of Mining Engineering, 32(2), 156-171.

3. Zhang, L., et al. (2021). Safety Considerations in Underground Mining: The Role of Motor Selection. International Journal of Mining Safety, 18(4), 412-428.

4. Anderson, K. (2018). Comparative Analysis of Motor Types for Mine Hoist Applications. Mining Equipment and Electrotechnology, 29(1), 45-62.

5. Patel, S. & Lee, J. (2022). Optimization of Power Consumption in Modern Mining Operations. Energy Efficiency in Industry, 14(3), 287-303.

6. Rodriguez, E. (2020). Variable Load Management in Mining: Motor Solutions and Strategies. Advanced Industrial Systems, 37(2), 189-205.