Essential Protective Equipment for 6600V Motor Operation

When working with high-voltage equipment like 6600V motors, proper personal protective equipment (PPE) is non-negotiable. The right gear can mean the difference between life and death in the event of an electrical accident.

Insulating Gloves and Sleeves

Insulating gloves and sleeves are absolutely vital for anyone working around 6600V motors, as they provide the first line of defense against direct contact with high-voltage electrical currents. Electrical workers must use rubber gloves that are specifically rated for voltages up to 7,500V, ensuring they meet international safety standards. These gloves should always be carefully inspected before use for signs of wear, cuts, or punctures, and must be regularly tested in compliance with safety regulations. Insulating sleeves offer extended protection, covering areas of the arms that may be exposed during operation or maintenance, further reducing the risk of accidental contact.

Arc-Rated Face Shields and Clothing

Arc flash hazards present one of the greatest dangers when working with high-voltage motors, making arc-rated face shields and clothing essential protective gear. These specialized garments are designed to withstand extreme heat, intense light, and flying debris generated by an arc flash event. Workers must wear face shields that not only cover the face but also provide side protection to reduce injury risk. In addition, arc-rated jackets, coveralls, and other garments shield the body from burns and other heat-related injuries. Using properly rated clothing ensures that workers are significantly safer when unexpected electrical arcs occur.

Insulated Tools

Every tool used near 6600V motors must be insulated to minimize the risk of accidental electrocution. Insulated screwdrivers, pliers, cutters, and voltage testers are manufactured with non-conductive materials that prevent current from traveling through the tool to the user. These tools must comply with recognized standards such as IEC 60900 to ensure maximum protection. Regular inspections are crucial to check for cracks, damage, or wear on the insulation coating. By ensuring all equipment is insulated, workers can perform tasks such as tightening connections or testing circuits with greater confidence and safety, even in high-risk environments.

Safety Footwear

Proper safety footwear plays an often-overlooked but critical role in protecting workers from electrical hazards. Electrical hazard (EH) rated safety boots are designed with insulating soles that reduce the likelihood of current passing through the wearer's body to the ground. These boots must be comfortable enough for long work shifts while still meeting stringent protective standards. In addition to preventing shocks, they also offer traditional safety features such as slip resistance and reinforced toes, making them suitable for industrial environments. When combined with other protective equipment, EH-rated boots provide an essential final barrier against electrical injuries.

Training Requirements for High Voltage Motor Handlers

Proper training is essential for anyone working with or around 6600V motors. This training should cover both theoretical knowledge and practical skills to ensure safe operation and maintenance.

Electrical Safety Fundamentals

Workers must have a solid understanding of electrical theory, including voltage, current, and resistance. They should also be well-versed in the specific hazards associated with high-voltage equipment.

Lock-Out/Tag-Out Procedures

Proper lock-out/tag-out procedures are critical for preventing accidental energization of 6600V motors during maintenance or repair. Workers must be trained in these procedures and understand their importance.

PPE Selection and Use

Training should cover the proper selection, inspection, and use of all required PPE. This includes understanding the limitations of each piece of equipment and when to replace or retest it.

Motor-Specific Training

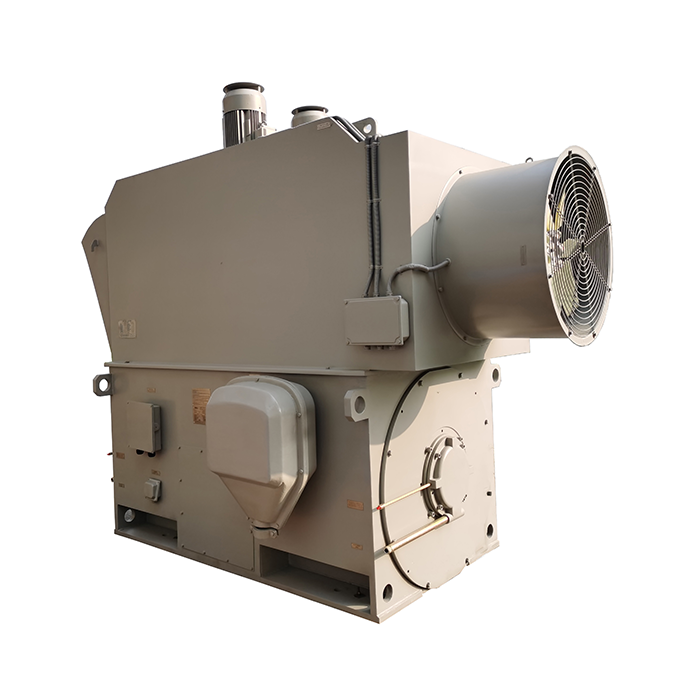

Workers should receive training specific to the 6600V motors they will be operating or maintaining. This includes understanding the motor's construction, operation principles, and common failure modes.

Emergency Response Training

All personnel working with high-voltage equipment should be trained in emergency response procedures, including first aid for electrical injuries and fire suppression techniques.

Emergency Procedures: What Every Operator Should Know?

Despite the best precautions, emergencies can still occur when working with 6600V motors. Having well-established emergency procedures and ensuring all operators are familiar with them is crucial for minimizing harm in critical situations.

Electrical Fire Response

In the event of an electrical fire involving a 6600V motor, operators should:

- Immediately de-energize the equipment if it's safe to do so

- Use only Class C fire extinguishers designed for electrical fires

- Never use water to extinguish an electrical fire

- Evacuate the area if the fire cannot be safely contained

Arc Flash Response

If an arc flash occurs:

- Move away from the arc flash as quickly as possible

- Do not attempt to remove any clothing that may be on fire - stop, drop, and roll instead

- Seek immediate medical attention, even if injuries seem minor

Electrical Shock Response

If a worker receives an electrical shock from a 6600V motor:

- Do not touch the victim if they are still in contact with the electrical source

- De-energize the equipment immediately

- Call for emergency medical assistance

- Administer CPR if the victim is unresponsive and not breathing

Equipment Failure Procedures

In case of sudden 6600V motor failure:

- Shut down the motor immediately using emergency stop procedures

- Isolate the motor from its power source

- Assess for any potential hazards such as smoke, unusual odors, or visible damage

- Report the incident to supervisors and maintenance personnel

Evacuation Procedures

Establish clear evacuation routes and assembly points in case of major incidents involving 6600V motors. Conduct regular drills to ensure all personnel are familiar with these procedures.

Call to Action

When it comes to motors powered by high voltages, XCMOTOR knows how important safety is. Robust insulating systems and smart protective mechanisms are integrated into our 6600V motors with safety as a top concern. We guarantee that your team can run our equipment safely and efficiently by providing top-quality motors and offering extensive training and support. If you are looking for high-performance motors that are supported by experienced expertise and a constant dedication to safety, XCMOTOR is the brand for you. Contact us today at xcmotors@163.com to learn how we can power your operations safely and effectively.