Safety First: Exde Motors in Explosive Atmospheres

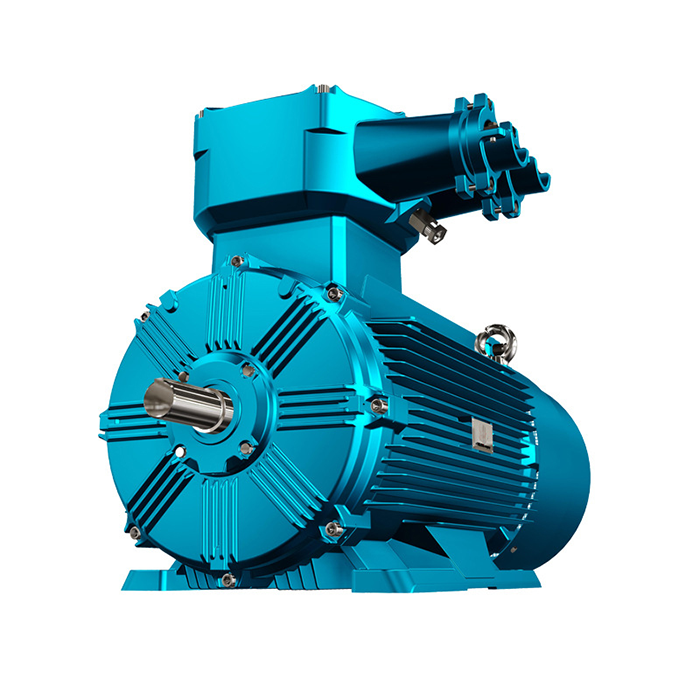

Exde motors, also known as explosion-proof or flameproof motors, are engineered to prevent the ignition of surrounding explosive atmospheres. Their robust construction and innovative design features make them essential components in hazardous locations.

Understanding Exde Motor Construction

The construction of exde motors are a marvel of engineering, specifically designed to contain any potential explosion within the motor housing. This containment prevents the spread of flames or sparks to the surrounding environment, effectively neutralizing the risk of a larger explosion.

Key features of the product construction include:

- Reinforced motor housings capable of withstanding internal explosions

- Flame-tight joints and gaps that allow pressure release but prevent flame propagation

- Specialized terminal boxes for safe electrical connections

- High-quality materials resistant to corrosion and wear

Operating Principles of Exde Motors

Exde motors operate on the principle of containment. In the event of an internal explosion, the motor's robust casing contains the pressure and flames, allowing them to cool as they escape through carefully designed flame paths. This process ensures that any escaping gases are below the ignition temperature of the surrounding atmosphere.

Case Studies: Exde Motors Preventing Industrial Disasters

The implementation of exde motors has been instrumental in preventing potential disasters across various industries. Let's examine some real-world examples that demonstrate the critical role these motors play in maintaining safety and operational continuity.

Oil Refinery Operations

In a major oil refinery, exde motors are utilized in pumping stations where flammable hydrocarbons are present. During a routine maintenance check, technicians discovered that one of the motors had contained a small internal explosion without any external signs of distress. This incident highlighted the effectiveness of the product's design in preventing a potentially catastrophic event.

Chemical Processing Plant

A chemical processing plant dealing with volatile organic compounds implemented exde motors throughout its facility. During an unexpected power surge, several motors in a high-risk area experienced electrical faults. Thanks to their explosion-proof design, the faults were contained within the motors, preventing any ignition of the surrounding flammable atmosphere.

Underground Mining Operations

In a coal mine where methane gas pockets are a constant concern, exde motors are used to power ventilation systems. When a methane detector signaled elevated gas levels in one section of the mine, the exde motors continued to operate safely, maintaining crucial air circulation and allowing miners to evacuate without incident.

Regulatory Compliance: Exde Motors and Industry Standards

The use of exde motors is not just a matter of best practice; it's often a regulatory requirement in hazardous environments. Understanding and adhering to these standards is crucial for businesses operating in potentially explosive atmospheres.

International Explosion Protection Standards

Several international standards govern the design, manufacturing, and use of explosion-proof equipment, including exde motors:

- IEC 60079 series: International standards for electrical equipment in explosive atmospheres

- ATEX Directive: European Union regulations for equipment used in potentially explosive atmospheres

- NEC 500 and 505: North American standards for hazardous location classifications

These standards define the requirements for different types of protection, including the 'Ex d' designation for flameproof enclosures used in the products.

Certification and Testing Requirements

Exde motors must undergo rigorous testing and certification processes to ensure they meet the stringent safety requirements for use in hazardous locations. These processes typically include:

- Type testing to verify the motor's ability to contain explosions

- Routine tests on every manufactured unit

- Quality assurance checks to maintain consistent production standards

- Third-party certification from recognized testing laboratories

Maintenance and Inspection Protocols

To maintain their explosion-proof integrity, exde motors require specific maintenance and inspection protocols. These may include:

- Regular visual inspections for signs of damage or wear

- Periodic testing of flame paths and enclosure integrity

- Proper reassembly procedures after maintenance to ensure flame-tight joints

- Documentation of all maintenance activities and inspections

Call to Action

Protecting your operations in dangerous conditions is our top priority at XCMOTOR. In addition to providing outstanding performance, our exde motors are designed to fulfil the most stringent safety requirements. 380V, 660V, and 415V are just a few of the voltage options available for our motors, which allow them to satisfy a wide variety of industrial demands. Their power ranges from 0.55kW to 355kW. Thanks to our exde motors' worldwide certifications and stringent quality control measures, you may use them with confidence. For explosion-proof motor solutions, go no further than XCMOTOR. We won't let you down on efficiency or safety.

Ready to enhance your industrial safety? Contact our team of experts today at xcmotors@163.com to discuss how our products can benefit your operations. Let's work together to create a safer, more efficient industrial environment.