To keep people and equipment safe while running a 630 kw motor, safety rules must be followed to the letter. These powerful industrial motors come with their own set of dangers, such as electrical shock, mechanical injury, and heat. Knowing the right safety rules keeps accidents from happening and makes equipment work better and last longer. Following safety rules is important for smooth operations and following the law, no matter what field you're in, whether it's manufacturing, process control, or energy generation. Because these electric motors put out a lot of power, they need to be treated with care and respect during installation, operation, and maintenance.

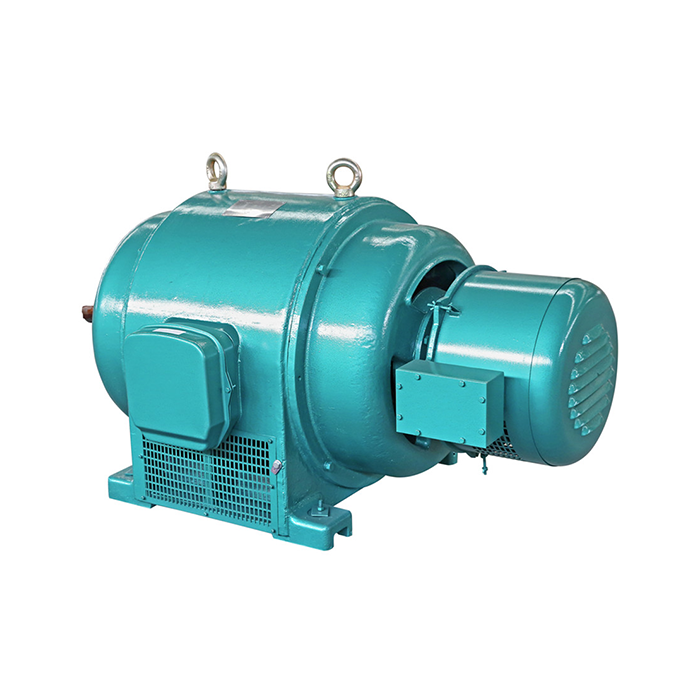

Series:YVF2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Knowing the dangers of high-power motors

Operators need to be aware of and reduce the risks that come with using high-power industrial motors. Electrical hazards are the most important, especially since these types of applications usually use three-phase voltage ranges of 3,000V to 11,000V. If you don't take the right steps, arc flash incidents can cause serious burns and even death.

Mechanical dangers are just as dangerous when a 630 kw motor is running. If the couplings aren't aligned properly, the huge amount of torque these units make can cause equipment to break down completely. People who are working nearby are at risk of getting pinched or getting stuck in rotating shafts and exposed mechanical parts.

Thermal factors are also important to think about because the motor windings and cooling systems work at high temperatures. If there isn't enough ventilation, the motor can overheat, which can lower its efficiency and even cause the insulation to break down. Knowing these basic risks is the first step in making complete safety rules.

Safety Checks Before the Operation

A lot of safety problems can be avoided by doing thorough checks before starting work. Looking at the 630 kw motor housing, connections, and nearby equipment can show problems that could get worse while the motor is running. Look for loose bolts, broken insulation, or signs of overheating from work that was done before.

During inspections, electrical connections need to be looked at very carefully. Check that all grounding systems are working correctly and that safety devices like circuit breakers and motor protection relays are working within the limits set. Use the right measuring tools to check the insulation resistance to make sure the motor winding is still good.

Checking the cooling system is very important for keeping safe operating temperatures. Make sure the air filters are clean, the fans are working, and there is enough space around the ventilation openings. Blocked cooling passages can make temperatures rise quickly, which can be dangerous and make equipment less reliable.

Documentation is very important for systematic inspections. Keep detailed records of all checks, including any strange readings or measurements that were found. This information helps find problems that are getting worse before they become safety risks.

Rules for Electrical Safety

When working with high-voltage systems, you need to follow strict electrical safety rules. Before you start working on motor circuits, make sure that all power is completely off. Lockout/tagout procedures should be followed to keep equipment from being turned on by accident while maintenance is going on.

When you work near energized equipment, you must wear personal protective equipment. Clothes that are arc-rated, gloves that are insulated, and safety glasses protect you from electrical dangers. To find the right PPE categories for certain jobs, figure out the incident energy levels.

These motors are often controlled by variable frequency drives, which add extra safety concerns. Check to see that the drive systems are properly grounded and that all of the safety interlocks work. Know that VFDs can keep dangerous voltages even after the power is turned off.

When more than one person works on electrical systems, make sure they all know how to talk to each other. Choose one person to be in charge of energy isolation and make sure that everyone on the team knows what they need to do to keep the electrical system safe.

Safety Measures for Machines

People are safe from the dangers of rotating equipment when they follow the right mechanical safety rules. Put the right guards around motor shafts, couplings, and driven equipment. Make sure that the guards meet safety standards and stay securely fastened while they are in use.

Because these 630 kw motors have a lot of torque, alignment procedures need to be done very carefully. When installing or fixing heavy motor parts, make sure to use the right tools to lift them. Never try to move motors without the right tools.

Things like safety and motor performance are affected by load capacity. Check that the mounting structures can handle the changing forces that happen when the system is running, such as starting transients and possible fault conditions. Poor mounting can cause dangerous levels of vibration.

Set up exclusion zones around working equipment to keep people away from mechanical hazards. Make sure all workers know how dangerous rotating machinery is by putting up clear warning signs.

Safety for the environment and installation

Environmental factors have a big effect on how safe and well a motor works. Make sure there is enough airflow to keep the heat from building up, which could damage the motor insulation or make it uncomfortable to work. Think about how the temperature around the motor affects its efficiency and change the way it works accordingly.

Many safety problems can be avoided by using the right installation methods. Follow the manufacturer's instructions for how to mount, align, and connect things. Use the right amount of torque for all fasteners, and make sure that the installation meets all relevant codes and standards.

In many industrial settings, protecting against moisture becomes very important. Check that the IP54 protection rating is enough for the specific conditions of your application. Think about extra safety measures in very bad conditions.

The noise from high-power motors can be too loud for people to be safe. To keep people safe while they work around equipment that is running, set up hearing protection programs and think about using acoustic enclosures when necessary.

How to respond in an emergency

When something goes wrong, well-thought-out emergency plans help keep injuries from getting worse. Make sure you have clear procedures in place for electrical emergencies, such as arc flash and shock response. Make sure that emergency shutoff devices are easy to find and clearly marked.

Teach employees how to respond to emergencies correctly, including how to give first aid for electrical injuries. Keep emergency contact information up to date and make sure that qualified medical help can get to serious situations quickly.

Common failure modes, such as overheating, too much vibration, or strange noises, should be covered by equipment emergency procedures. Set clear rules for when to turn off equipment right away and when to keep an eye on it. In an emergency, communication systems are very important. Make sure there are reliable ways to call for help and let the right people know about emergency situations. Drills on a regular basis help keep people ready to respond.

Things to think about for safety during maintenance

Because maintenance workers have to work on or near energized equipment, they face unique safety risks. Make sure that your maintenance procedures are complete and put worker safety first while also making sure that your equipment is well cared for.

When doing maintenance on motor starter systems, you need to be very careful. These parts can keep electrical energy even after the power is turned off. Before starting work, make sure you follow the right discharge procedures and check that everything is safe.

Maintaining bearings means working with moving parts and possibly dangerous lubricants. When you lift heavy motor parts, make sure to use the right techniques. Also, when you work with cleaning solvents, make sure there is enough air flow.

Monitoring energy use during maintenance can help find problems that are getting worse and could become safety risks. Keep an eye on the performance of the motor and look into any big changes from normal operating ranges.

Requirements for Training and Certification

The most important part of any 630 kw motor safety program is proper training. People who work with high-power motors should get a lot of training on electrical safety, mechanical hazards, and how to handle emergencies.

Different places and uses have different requirements for certification. Make sure that all employees have the right skills and knowledge for the tasks they are given. Regular refresher training keeps safety knowledge up to date and helps people learn about changes in procedures or equipment.

Hands-on training parts help students connect what they learn in theory with what they can do in real life. Give people chances to practice with real equipment under controlled conditions with supervision.

Keeping records of training activities is necessary for following the rules and making things better all the time. Keep detailed records of all training given and keep track of each person's competency assessments.

Conclusion

You need to know about electrical, mechanical, and environmental dangers in order to safely use high-power motors. Good training, thorough inspections, and safety rules keep people and equipment safe. The motor will run safely for its whole life if you follow the maintenance and emergency procedures. By following these safety rules, businesses can get the most work done and lower the risks of industrial motor operation. Everyone is responsible for safety, and being on the lookout all the time can help avoid accidents that could hurt people and shut down operations.

Choose XCMOTOR as Your Trusted Maker of 630 kW Motors

Suppliers who know a lot about industrial motors and how to use them safely need to provide reliable equipment. XCMOTOR makes motors that are safe to use and work well in a variety of situations. Our 630 kw motor design has cutting-edge safety features like motor protection systems, the best insulation classes, and better cooling systems. These features make the equipment more reliable and lower the risks of using it.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers technical help and quick responses for all of its motors. Our team knows how important your operations are and has the knowledge to keep your motors running safely and efficiently. Our motors are strong and dependable enough to work with pumps, compressors, and other tough jobs. We ship quickly, let you return items within 30 days, and are available 24/7 to help with urgent problems.

Ready to upgrade your motor systems with equipment designed for both safety and performance? Our experienced team can help you select the right motor configuration for your specific application requirements. Contact us at xcmotors@163.com to discuss your project needs and discover why leading companies trust our motor solutions for their most critical applications.

References

- National Electric Code (NEC), Article 430: Motors, Motor Circuits, and Controllers, National Fire Protection Association, 2023.

- IEEE Standard 43-2013: IEEE Recommended Practice for Testing Insulation Resistance of Rotating Machinery, Institute of Electrical and Electronics Engineers, 2013.

- NEMA MG 1-2016: Motors and Generators Standards, National Electrical Manufacturers Association, 2016.

- OSHA 29 CFR 1910.147: Control of Hazardous Energy (Lockout/Tagout) Standards, Occupational Safety and Health Administration, 2022.

- IEC 60034-1:2017: Rotating Electrical Machines - Part 1: Rating and Performance, International Electrotechnical Commission, 2017.

- NFPA 70E-2021: Standard for Electrical Safety in the Workplace, National Fire Protection Association, 2021.