As businesses look for efficient ways to power a wide range of applications, the global market for DC motors keeps growing. These motors are very important for many manufacturing industries, including as automotive, aerospace, electronics, and food processing. Also, HVAC and refrigeration systems, energy producing facilities, and renewable energy initiatives all need reliable motor solutions. As more and more sectors automate, the need for precision-engineered motors that work well no matter what load they are under has grown.To find trustworthy suppliers for a 20 hp dc electric motor, you need to carefully look at their manufacturing capabilities, quality standards, and technical requirements. This complete guide shows you all the steps you need to take to find reliable manufacturers who can provide high-quality DC motors that match your business needs. Knowing how to source motors for manufacturing automation, HVAC systems, or energy applications lets you make smart choices that affect how well your business runs.

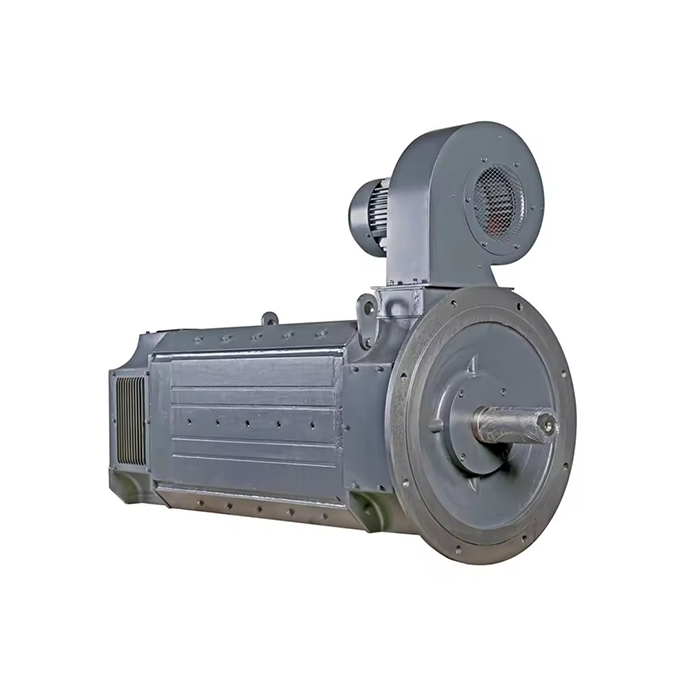

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Why China is the Best Place to Make 20 HP DC Motors

Infrastructure for Advanced Manufacturing

China's motor manufacturing sector has evolved and improved due to technology and industry. The country has advanced industrial facilities with computer-controlled machines, precision testing equipment, and automated assembly lines. These skills allow manufacturers to build high-quality motors with tight tolerances. Many facilities use quality management systems to ensure each unit meets performance standards.

Technical Knowledge and New Ideas

Chinese companies have put a lot of money into research and development, which has led to the creation of motors that use the latest technologies. Engineers use better magnetic designs, better materials, and better cooling systems to make motors work better. The 20 hp dc electric motors, which range from 1.5 to 600 kW, are a good example of this new technology because they have better dynamic performance and can work with both DC unit and static rectifier power supplies.

Production capabilities that save money

A competent workforce, effective supply chains, and economies of scale all work together to keep prices low without sacrificing quality. Manufacturers can provide unique voltage options, specialized mounting configurations, and application-specific changes at prices that are fair. This versatility is helpful when looking for motors for certain industrial needs or retrofitting projects.

Important Factors to Consider When Choosing Reliable Motor Manufacturers

Assessing Production Capacity

Check the manufacturer's output, the size of their facilities, and the capabilities of their equipment. Reliable suppliers have enough capacity to manage the amount of your order and still achieve delivery deadlines. To learn more about how they make things and how they make sure the quality is good, you can either visit their websites or ask for tours of their facilities.

Checking the Technical Specifications

Check the detailed specs, such as power ratings, voltage ranges, speed capabilities, and efficiency ratings. A 20 hp dc electric motor should work well at all speeds. Check that the parameters match what you need for your application, such as beginning torque, overload capacity, and the conditions in which it will be used.

References from customers and case studies

Ask current clients in related fields for recommendations. Call these references to ask about how well the product works, how reliable the delivery is, and how good the after-sales service is. Manufacturers with a good track record are happy to give customer reviews and case studies showing how well their products work.

Engineering Support Skills

Check to see if the manufacturer can help you with technical issues during the selection, installation, and operating phases. Good vendors give you all the paperwork you need, wiring diagrams, maintenance tips, and help with problems. This help is very useful for adding motors to systems that are already in place or making new applications.

Systems for Managing Quality

Look at the manufacturer's quality control methods, testing methods, and record-keeping methods. Reliable vendors use thorough testing procedures to make sure that their products meet safety, performance, and durability standards. Before shipping, each motor should be thoroughly checked to make sure it meets all requirements.

Services for customizing and changing things

Find out if the manufacturer can change standard designs or make unique solutions. Industrial uses often need certain mounting setups, unique voltage ratings, or characteristics that safeguard the environment. Flexible producers can provide these needs while still keeping up with quality standards.

Stability in the Supply Chain

Look at the manufacturer's relationships with their suppliers, how they get parts, and how they keep track of their stock. Stable supply chains make sure that products are always available and that deliveries are as quick as possible. Using high-quality bearings from well-known companies shows that manufacturers care about the quality of their parts.

Important Certification Requirements for Buying DC Motors

International Quality Standards

ISO 9001:2015 certification reflects the company's commitment to quality management and improvement. This standard ensures consistent processes, established procedures, and customer satisfaction. Manufacturers holding this accreditation are regularly inspected to ensure compliance.

Certifications for Safety and Performance

Products with the CE certification meet European health, safety, and environmental regulations. This certification is crucial when supplying motors to European markets or when clients need CE-compliant equipment. Following national standards like GB/T755 and international standards like VDE0530 ensures product acceptance in many markets.

Following the rules for the environment

RoHS certification shows that 20 hp dc electric motors don't contain any harmful compounds, which helps protect the environment. Many businesses need RoHS-compliant parts to meet their own environmental and legal obligations.

Certifications for certain industries

Some jobs need particular certificates for things like protecting against explosions, working in aquatic areas, or following food processing requirements. Find out what unique certification criteria your industry has and make sure that potential suppliers can offer items that meet those standards.

Choosing the Right Sourcing Channels and Platforms

Getting in touch with the manufacturer directly

Building direct ties with manufacturers is frequently the greatest way to get the best prices, technical support, and customization options. Direct interaction makes it easy to talk about specs, delivery needs, and quality expectations. Companies like XCMOTOR provide full assistance with their own sales and engineering teams.

Exhibitions and trade shows for businesses

At motor and automation trade fairs, you may meet manufacturers in person, look at product samples, and talk about technical needs. These gatherings let people get to know each other better and let them compare a lot of vendors in a short amount of time.

Professional networks and groups in the same field

Use your professional contacts and resources from industry groups to find trustworthy suppliers. People that work in the same field as you often offer useful information on how well suppliers do and how reliable their products are.

B2B Platforms on the Internet

There are a number of online marketplaces that connect purchasers with real manufacturers. These sites usually offer ratings of suppliers, evaluations from customers, and services that protect transactions. However, check the credentials of suppliers on your own and do your homework before making a purchase.

Getting the Most Out of OEM and ODM Partnerships

Clear Specifications Documentation

Write detailed specs for technical, quality, and delivery demands. Include performance, ambient, installation, and testing criteria. Clear documentation ensures quality and avoids misunderstandings.

Intellectual Property Protection

Protect your IP, design specs, and trade secrets with contracts. Establish privacy guidelines and identify who owns joint innovations and improvements.

Quality Control Rules

Perform inspections and tests during manufacturing. Set acceptance, sampling, and paperwork criteria. Regular quality audits raise standards and improve processes.

Communication frameworks

Set up clear channels to communicate, report issues, and escalate. Milestone reviews and project updates help prevent issues. Designate technical, business, and quality contacts.

Strategic Ways to Talk About MOQ and Prices

Learning Minimum Order Quantities

Based on production and setup expenses, manufacturers determine minimum order quantities. Knowing your needs helps you plan purchases and stockpiles. First orders and new business collaborations may be flexible with some suppliers.

Volume-Based Pricing Strategies

Create price structures that reflect long-term volume forecasts. Many companies have tiered pricing, which lowers as quantity increases. Consider annual contracts that stabilize pricing and guarantee supply.

Total Cost of Ownership Analysis

Consider prices beyond the initial purchase. Consider energy use, maintenance, lifespan, and warranty conditions. More efficient motors may be worth the extra money because they run cheaper.

Payment Terms

Talk to your suppliers on payment terms that fit your cash flow and financial rules. For large orders or new supplier agreements, consider letters of credit, staged payments, or performance-based payment schemes.

Complete guidelines for factory audits and quality assurance

Evaluation of the production facility

Check out the organization of the workplace, the layout of the production area, and the equipment used for manufacture. Modern buildings show that you care about quality and efficiency. Check the schedules for calibrating, maintaining, and training operators on the equipment.

Review of the Quality Management System

Check the quality documents, the testing procedures, and the steps for taking remedial action. Look at recent audit findings, customer complaints, and plans to make things better. Good quality systems stop problems from happening and make sure that products are always of high quality.

Evaluation of the Supply Chain

Check the processes for qualifying suppliers, inspecting parts, and managing inventory. Reliable manufacturers keep lists of recognized suppliers and check on them regularly.

Testing and Validating Skills

Look at the testing equipment, calibration records, and validation steps. Comprehensive testing makes sure that motors fulfill safety and performance standards. Check that the testing capabilities meet your standards for quality.

Conclusion

To get 20 hp dc electric motors, manufacturers must be evaluated, technical requirements understood, and quality standards observed. Advanced production, reasonable cost, and wide customization make Chinese manufacturing appealing. However, success hinges on choosing manufacturers with consistent quality, reliable delivery, and extensive support. Successful supplier relationships need clear communication, expectations, and teamwork. Manufacturers with contemporary production facilities, high quality standards, and great customer service offer the highest long-term value. This guide will help you find vendors who fit your needs and provide reliable motor performance for industrial applications.

Frequently Asked Questions

Q1: What voltages do 20 hp dc electric motors have?

A: Most manufacturers offer 160V, 400V, and 440V. Many providers customize voltage ratings for specific applications. During specification, discuss voltage demands to guarantee compatibility with your electrical systems.

Q2: How can I check DC motor manufacturing quality?

A: Ensure ISO 9001:2015 certification, CE marking, and technical standard compliance. Customer references, quality documentation, and factory audits are options. Reliable manufacturers provide precise specs, test reports, and performance statistics.

Q3: What are custom motor order lead times?

A: Standard motors arrive in 2-4 weeks, whereas special combinations take 6-12 weeks depending on complexity. Early in procurement, discuss delivery requirements and evaluate key application safety stock.

Partner with XCMOTOR for Reliable 20 HP DC Motor Solutions

XCMOTOR stands ready to meet your industrial motor requirements with high-quality 20 hp dc electric motor solutions designed for demanding applications. Our Z4 series motors deliver exceptional performance with efficiency ratings up to 91% and superior dynamic characteristics that outperform traditional designs. We maintain strict quality standards while offering competitive pricing and flexible customization options. Our experienced engineering team provides comprehensive technical support from initial specification through installation and ongoing maintenance. We understand the unique requirements of manufacturing automation, HVAC systems, and energy applications. Whether you need a single motor or large-quantity procurement, we deliver reliable solutions that exceed expectations.

As a trusted 20 hp dc electric motor manufacturer, we offer 30-day returns, fast delivery, and dedicated support seven days a week. Contact our team to discuss your specific requirements and discover why customers choose XCMOTOR for their critical motor applications. Reach out to our specialists today at xcmotors@163.com and experience the difference that quality engineering and exceptional service make for your operations.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance Standards." IEC Publication 60034-1, 2017.

2. Chen, Wei and Liu, Ming. "Advanced DC Motor Design for Industrial Applications." Journal of Electrical Engineering Technology, Vol. 15, No. 3, 2020.

3. National Institute of Standards and Technology. "Energy Efficiency Standards for Electric Motors." NIST Special Publication 1200-25, 2019.

4. Zhang, Xiaofeng. "Quality Management Systems in Chinese Motor Manufacturing." International Journal of Production Quality Management, Vol. 28, No. 4, 2021.

5. European Committee for Standardization. "Rotating Electrical Machines - Specifications and Testing Methods." EN 60034 Series Standards, 2018.

6. Wang, Jianhua and Brown, Robert. "Supply Chain Management in Global Motor Manufacturing." Industrial Engineering Research Quarterly, Vol. 42, No. 2, 2022.