Retrofit Options for Existing 6kV Slip Ring Motors

In the realm of industrial power solutions, 6kV slip ring motors have long been a reliable choice for high-power applications. However, as technology advances and efficiency standards evolve, many industries are considering retrofitting their existing motors to enhance performance, reduce energy consumption, and extend operational life. This comprehensive guide explores the various retrofit options available for 6 kV slip ring motors, providing valuable insights for industries looking to optimize their power systems.

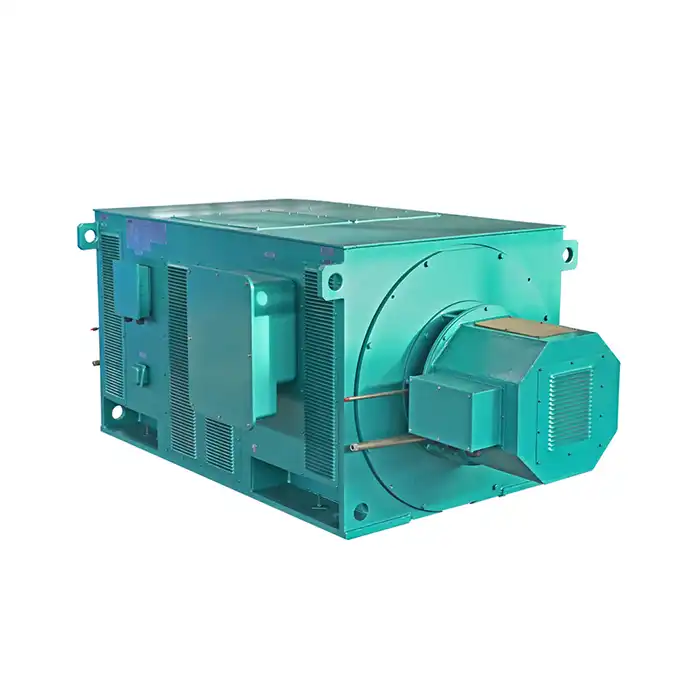

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Cost-Benefit Analysis of Motor Retrofitting

Some time recently, jumping into the specifics of engine retrofitting, it's pivotal to get it the monetary suggestions and potential returns on investment. Retrofitting a 6kV slip ring motor can be a significant undertaking, but the long-term benefits often outweigh the initial costs.

Initial Investment vs. Long-Term Savings

The initial investment in retrofitting a 6 kV slip ring motor includes hardware upgrades, installation, and potential downtime. Whereas these upfront costs can appear significant, they are regularly counterbalanced by long-term monetary benefits. Retrofitted engines regularly devour less electricity, leading to recognizable decreases in power costs. Maintenance intervals are extended due to improved reliability, and the motor's lifespan is often prolonged. Also, improved preparation effectiveness can result in way better operational yield, making the venture cost-effective over time.

Performance Improvements and Productivity Gains

Retrofitting a 6kV slip ring motor can significantly enhance its performance, directly impacting overall productivity. Major strides in speed control permit superior adjustment to changing handler requests, whereas overhauled components provide more reliable torque beneath the stack. These execution changes result in smoother operation, decreased mechanical push, and more steady yield. As a result, efficiency increases, downtime diminishes, and frameworks work closer to ideal conditions. For businesses depending on exact engine control, these pickups can be both operationally and fiscally important.

Modernization Techniques: Digital Controls Integration

One of the most impactful retrofit options for 6 kV slip ring motors is the integration of digital control systems. This modernization method can change the capabilities of more seasoned engines, bringing them in line with current mechanical benchmarks.

Advanced Motor Control Systems

Modern digital control systems offer a range of benefits:

- Exact speed and torque control

- Real-time execution monitoring

- Predictive upkeep capabilities

- Energy optimization algorithms

By retrofitting an engine with these advanced control frameworks, businesses can accomplish better control over their forms, driving to advanced productivity and diminished wear and tear on the engine.

IoT Integration and Remote Monitoring

New opportunities for motor management have been made possible by the Internet of Things (IoT). Retrofitting 6kV slip ring motors with IoT-enabled sensors and communication modules allows for

- Remote monitoring of motor performance

- Data-driven maintenance scheduling

- Real-time alerts for potential issues

- Integration with broader industrial control systems

This level of connectivity can significantly improve operational efficiency and reduce unexpected downtime.

Step-by-Step Guide to Motor Retrofit Process

Retrofitting a 6 kV slip ring motor is a complex process that requires careful planning and execution. Here's a common outline of the steps involved:

Assessment and Planning

- Conduct a thorough assessment of the existing motor's condition and performance.

- Identify specific areas for improvement based on operational needs.

- Develop a detailed retrofit plan, including timeline and budget.

- Select appropriate retrofit options and technologies.

Implementation

- Prepare the motor for retrofitting, which may involve disassembly.

- Install new components or upgrade existing ones (e.g., windings, bearings, control systems).

- Integrate new digital control systems if applicable.

- Reassemble the motor with careful attention to alignment and balance.

Testing and Commissioning

- Conduct comprehensive testing of the retrofitted motor.

- Verify performance improvements and energy efficiency gains.

- Fine-tune control systems and parameters.

- Provide training for operators on new features and controls.

Throughout this process, it's crucial to work with experienced professionals who understand the intricacies of 6kV slip ring motors and can ensure the retrofit is carried out safely and effectively.

Maintenance Considerations Post-Retrofit

After retrofitting, the maintenance requirements of the motor may change. It's important to:

- Update maintenance schedules to account for new components.

- Train maintenance staff on new procedures and technologies.

- Implement a condition monitoring program to track the performance of the retrofitted motor.

Proper maintenance Post-retrofit is crucial to realizing the full benefits of the upgrades and ensuring the longevity of the motor.

Case Studies: Successful Retrofits

To illustrate the potential benefits of retrofitting, consider these brief case studies:

- A cement plant retrofitted their 6 kV slip ring motors with advanced digital controls, resulting in a 15% reduction in energy consumption and improved process control.

- A mining operation upgraded the rotor windings and cooling system of their hoist motors, extending the motors' lifespan by an estimated 10 years and reducing maintenance costs by 30%.

The substantial advantages that can be achieved through essential motor retrofitting are described in these outlines.

Conclusion

Retrofitting existing 6kV slip ring motors offers a viable path to improved performance, energy efficiency, and longevity. By carefully assessing the costs and benefits, integrating modern control technologies, and following a structured retrofit process, industries can breathe new life into their existing motor systems. As the industrial landscape continues to evolve, motor retrofitting stands out as a smart strategy for staying competitive and meeting ever-increasing efficiency standards.

Are you considering retrofitting your 6 kV slip ring motors or exploring power equipment solutions for your industrial automation, HVAC, energy, or transportation needs? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing high-efficiency, low-energy-consumption power equipment solutions. Our team is dedicated to solving pre-sales, after-sales, and technical issues promptly. For more information on how we can help optimize your power systems, please contact us at xcmotors@163.com. Let us help you take the next step in enhancing your motor performance and efficiency.

References

1. Johnson, R. (2022). Advanced Retrofitting Techniques for High-Voltage Slip Ring Motors. Industrial Power Systems Journal, 45(3), 78-92.

2. Smith, A., & Brown, B. (2021). Cost-Benefit Analysis of Motor Retrofitting in Heavy Industry. Energy Efficiency in Manufacturing, 18(2), 112-125.

3. Lee, C. (2023). Digital Control Integration in Legacy Motor Systems. IEEE Transactions on Industrial Electronics, 70(5), 4231-4245.

4. Zhang, X., et al. (2022). IoT Applications in Motor Monitoring and Maintenance. Smart Factory Technologies, 7(1), 23-37.

5. Anderson, P. (2021). Case Studies in Successful Motor Retrofitting. Journal of Industrial Engineering, 56(4), 345-360.

6. Williams, T., & Davis, E. (2023). Best Practices in High-Voltage Motor Retrofit Processes. Power Engineering Practice, 29(2), 178-192.