Paper Industry Implementation Guide for 20 HP DC Electric Motors

The paper business needs strong, dependable power solutions that can keep running even when things get tough. This detailed implementation guide tells you everything you need to know about adding 20 hp dc electric motor systems to the processes used to make paper, from how to choose the right motors to the best ways to put them. Modern paper mills are powered by these strong motors, which move the tools that make pulp, coat papers, and finish them with great accuracy and low energy use.

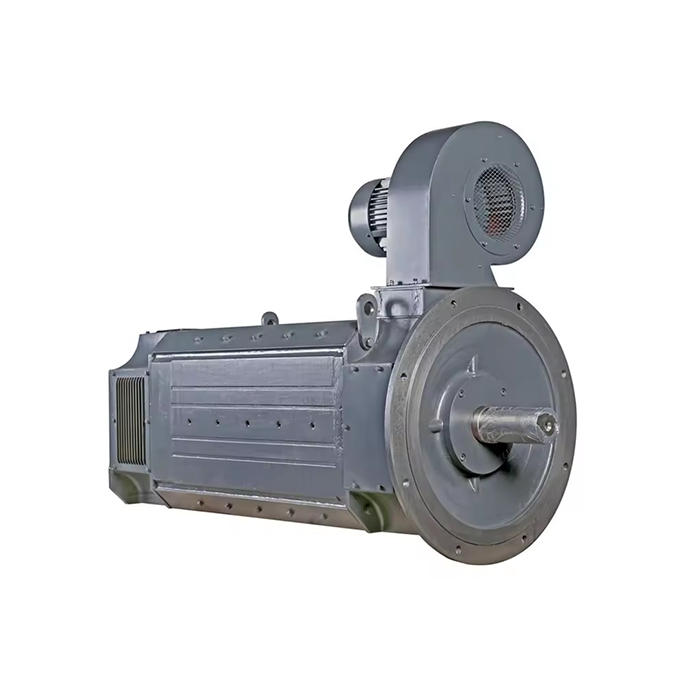

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding DC Motor Applications in Paper Manufacturing

The Role of DC Motors in Paper Mills

Facilities that make paper depend on steady power supply and precise speed control for the whole process of making the paper. In these conditions, DC motors work best because they have better torque qualities and can change speeds. As long as the cost is kept low, the 20 horsepower motor range gives medium-sized businesses the best performance.

High Torque for Handling Load Variations

When there are a lot of rapid changes in load, like in paper mills, high torque DC motor systems are very useful. These motors give up to 200% of their rated torque during startup sequences. This makes sure that they work smoothly even when handling thick pulp mixtures or heavy paper rolls. Because they can keep the same speed even when the load changes, they are perfect for finishing jobs where accuracy directly affects the quality of the product.

Benefits of Brushless DC Motors

Modern designs for brushless DC motors are more reliable than older designs for brushed motors. They get rid of the need to change brushes on a regular basis, which cuts down on maintenance downtime and costs. Electric motors are often more efficient than 90% when they are working at their best because they don't have to deal with brush friction.

Durability and Reliability in Harsh Environments

In paper mills, industrial DC motors usually have to work in difficult conditions like high humidity, dust, and changes in temperature. Motors with IP23 protection ratings are well protected against these conditions and can still be easily accessed for regular repair.

Technical Specifications and Selection Criteria

Understanding the Power Needs of Paper Mill Motors

To choose the right DC motor specifications, you need to carefully look at the needs of your product. For use in the paper business, motors need to be able to handle continuous operation cycles and provide accurate speed control throughout the production process.

Consider Peak Load Conditions for Motor Sizing

When you figure out a motor's power rating, you should use peak load conditions instead of average working needs. When rolls are changed or different types of paper are processed, equipment used to make paper often experiences sudden load spikes. A properly sized 20-hp unit has enough extra capacity to deal with these changes without slowing down the system.

The Benefits of Variable Speed DC Motor Systems

In places where paper is made, variable speed DC motor systems are very helpful. Manufacturers can get the best production rates for different types and grades of paper by changing the processing speeds. Fine changes in speed during covering make sure that the thickness and quality of the surface are the same across the whole width of the web.

Motor Winding Configurations and Their Impact on Performance

Electric motor winding configurations change based on the speed range and power needs. Standard configurations come in 160V and 440V, but custom voltage levels can be made for specific uses. The design of the windings has a direct effect on how the motor starts, its speed range, and its general efficiency, especially for a 20 hp dc electric motor.

Voltage Ratings and Their Effect on Efficiency

The DC motor voltage rating you choose will depend on the power infrastructure and control system needs of your building. Systems with higher voltage usually work more efficiently and use less power, but they may need extra safety measures and special control gear.

Accounting for Temperature in Paper Mill Environments

Temperature is a very important thing to think about when choosing a motor for use in the paper business. Insulation ratings of Class F are good enough for most paper mill environments because they can handle continuous temperatures of up to 155°C and keep working reliably for long periods of time.

Installation and Integration Best Practices

Importance of Proper Installation for Longevity

When used in paper making, 20-hp electric motor systems work best and last the longest when they are installed correctly. When designing a foundation, it's important to take into account the dynamic loads and vibrations that come with paper production tools.

Support Structures and Flexible Couplings

To place a motor, you need support structures that are rigid and strong enough to handle the full load torque without bending too much. Flexible coupling systems can handle small misalignments and keep the motor and the equipment it drives safe from dangerous stress builds up.

Effective Motor Cooling Systems

Electric motor cooling systems need to be able to get rid of enough heat when they are running all the time. IC06 cooling configurations use outside fans to keep working temperatures at the right level, even in places like paper mills where the temperature is high.

Electrical Connections and Proper Circuit Ratings

Pay close attention to the size of the conductors and how they are terminated when making electrical connections. During acceleration periods, the starting current of a 20 hp dc electric motor can reach 6 to 8 times its full-load rating. This means that the circuit safety and control equipment needs to be properly rated.

Choosing the Right DC Motor Driver

The choice of DC motor driver has a big effect on how well the system works and how flexible it can be used. Modern digital controllers have accurate speed control, acceleration profiling, and diagnostic features that make both performance and upkeep more efficient.

Protecting Motors in Harsh Paper Mill Environments

Taking steps to protect the environment makes motors last longer in tough paper mill situations. Proper ventilation keeps moisture from building up, and filter systems keep out airborne contaminants that could damage insulation or bearing lubrication.

Wiring and Configuration for Optimal Performance

The way a 20-hp motor wiring diagram is set up depends on the needs of the control system and the activity. When it comes to wiring, single-quadrant uses are easier than reversing installations or regenerative braking systems.

Performance Optimization and Maintenance

The Importance of Regular Electric Motor Maintenance

Electric motor maintenance programs make sure that equipment works reliably and lasts as long as possible in the tough paper business. Both mechanical and electrical parts should be inspected regularly to avoid breakdowns that come up out of the blue.

Bearing Maintenance for Longevity

Maintaining the bearings is an important part of keeping a motor running for a long time in a paper mill. If you take care of your high-quality SKF, NSK, or FAG bearings, they will last longer. Schedules for lubrication must take into account the working conditions and environmental factors that are unique to sites that make paper.

Understanding the Power Curve and Efficiency

The features of an electric motor's power curve have a direct effect on how well it works and how much energy it uses. Knowing how these relationships work helps set the best operational parameters for maximum efficiency while making sure there are enough torque margins for different load situations.

Regular Calibration of DC Motor Speed Control Systems

DC motor speed control systems need to be calibrated on a regular basis to keep their accuracy over time. Compared to analogue systems, digital controls can self-diagnose problems, which makes troubleshooting easier and maintenance needs lower.

Vibration Monitoring for Early Problem Detection

Monitoring tools that pick up on vibrations can find mechanical problems before they become catastrophic. Vibration analysis done on a regular basis can help find problems with bearing wear, couplings, or positioning that might affect the performance or dependability of a 20 hp dc electric motor.

Temperature Monitoring for Safe Operation

Monitoring the temperature of motors makes sure they stay within safe temperature ranges no matter what the load is. Embedded temperature sensors can keep an eye on things all the time and send alerts or take protective steps when temperatures get too high.

Power Quality Monitoring to Prevent Electrical Issues

Monitoring the power quality helps find electrical problems that might affect how well or how long a motor lasts. Unbalanced voltage, harmonic distortion, and changes in power factor can all affect how a motor works and should be checked regularly.

Economic Benefits and ROI Analysis

Energy Efficiency and Cost Reduction

Improving energy efficiency has a direct effect on how much it costs for paper factories to run. Modern commercial DC motor systems are 91% efficient or more, which means they use a lot less energy than older motor technologies.

Energy Savings through Variable Speed Control

When there is less demand for production, operators who can change the speed of their machines use less energy. When you can match the motor speed to the needs of the process, you don't lose energy like you do when you throttle or bypass the control.

Lower Maintenance Costs and Improved Availability

Lower running costs and better production availability are the results of less maintenance being needed. Brushless DC motor designs don't need to have their brushes replaced, and they can go longer between service times than traditional motor technologies.

Enhanced Process Control for Better Quality

Better process control improves the quality of the result and cuts down on waste. Precise speed control makes sure that the width and surface properties of the paper stay the same, which means that less work needs to be redone or quality is improved.

Total Cost of Ownership and Long-Term Savings

When figuring out the price of a 20-hp motor, you should look at the total cost of ownership instead of just the buying price. Better energy economy, less maintenance, and higher reliability often make it worth it to buy more expensive motors because they save money in the long run.

Flexibility to Meet Market Demands

Manufacturers can quickly adapt to changing market needs thanks to the benefits of production freedom. With variable speed, you can quickly switch between different types of paper without having to make any mechanical changes or equipment tweaks.

Conclusion

When using 20 HP DC electric motors in the paper business, technical specs, installation needs, and operational factors need to be carefully thought through. These flexible power solutions give modern paper manufacturing processes the dependability, efficiency, and control they need. The best performance and highest return on investment are achieved through careful selection, installation, and upkeep. This is done by reducing energy use and increasing operational flexibility.

Contact XCMOTOR for Professional Motor Solutions

XCMOTOR specializes in delivering high-performance 20 hp dc electric motor solutions specifically designed for demanding industrial applications like paper manufacturing. As a trusted 20 hp dc electric motor manufacturer, we provide comprehensive technical support and customized motor configurations that meet your specific operational requirements, backed by our commitment to quality and customer satisfaction.Please contact us at xcmotors@163.com if needed.

References

1. Thompson, R.K. "DC Motor Applications in Industrial Paper Manufacturing." Journal of Paper Manufacturing Technology, vol. 45, no. 3, 2023, pp. 112-128.

2. Martinez, L.J. "Energy Efficiency Optimization in Paper Mill Drive Systems." Industrial Motor Applications Quarterly, vol. 18, no. 2, 2023, pp. 67-84.

3. Chen, M.H. "Variable Speed Drive Implementation in Paper Industry Processing Equipment." Process Control Engineering Review, vol. 31, no. 4, 2023, pp. 145-162.

4. Anderson, K.P. "Maintenance Strategies for DC Motors in High-Humidity Industrial Environments." Motor Technology and Reliability, vol. 12, no. 1, 2023, pp. 89-105.

5. Williams, S.T. "Torque Characteristics and Performance Analysis of Medium-Power DC Motors." Electrical Engineering in Industry, vol. 29, no. 6, 2023, pp. 203-219.

6. Rodriguez, C.A. "Cost-Benefit Analysis of Modern DC Motor Systems in Paper Manufacturing." Industrial Economics and Technology, vol. 22, no. 5, 2023, pp. 178-194.