3.3 kV Motor vs 6.6 kV: Voltage Optimization for Your Plant

Power efficiency, operating costs, and system complexity are all factors to consider when choosing between a 3.3 kV Motor and a 6.6 kV Motor for industrial uses. The 3.3 kV Motor usually has better control accuracy and a cheaper initial investment. This makes it perfect for 160–1600 kW medium-power applications. On the other hand, 6.6 kV systems work best in high-power situations that need less current draw and easier connection infrastructure. Knowing about these differences in voltage helps makers run their plants more efficiently while keeping costs low and performance needs in mind.

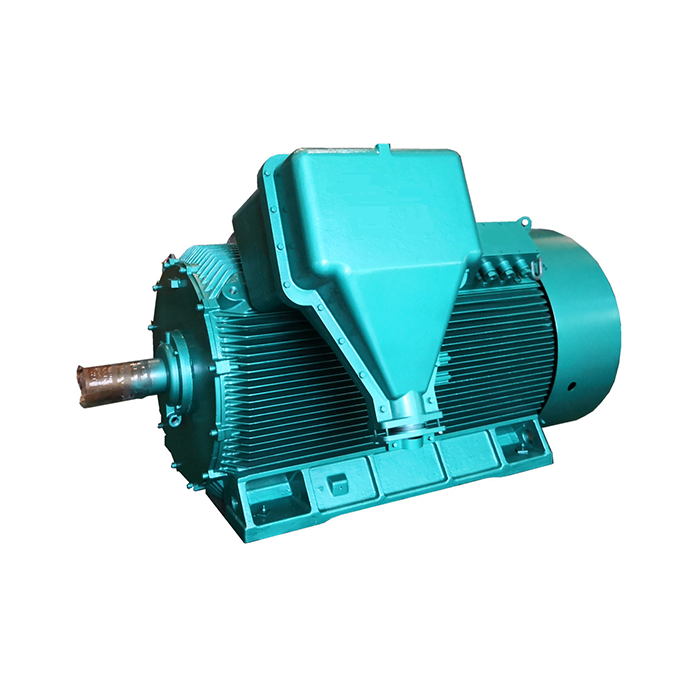

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Medium Voltage Motor Classifications

Medium voltage motors are the most important part of industrial machinery in the energy, HVAC, and manufacturing sectors. These electric motors work with voltage levels that are in between low voltage systems and high voltage gearbox gear.

Several important operational factors are based on the voltage classification

- Current needs: Higher voltage lowers the amount of current needed to produce the same amount of power.

- Cable size: choosing the voltage has a direct effect on the cable requirements.

- security systems: Different voltage levels need different motor security plans.

- Places that control motors: Infrastructure is very different between voltage classes

- How to do maintenance: Different amounts of voltage call for different safety measures.

As motor efficiency has gone up, medium voltage uses have become more appealing. Modern motor windings use high-tech shielding materials that make them more reliable while also using less energy. Variable frequency drives work best with these systems because they make motor speed control better in a wide range of operational situations.

3.3 kV systems have great motor torque characteristics if you need fine speed control with moderate power needs. In situations where more power is needed but less infrastructure complexity is needed, 6.6 kV setups work best.

Technical Specifications Comparison

Knowing the technical differences between voltage levels helps engineers choose the right motor for the job. Key success indicators are shown in the following comparison:

Analysis of the Power Range

- 3.3 kV motors are best for 160–1600 kW tasks.

- 6.6 kV motors work great in roles requiring 800–5000 kW or more.

- The overlap zone of 800-1600 kW gives you options.

How to Figure Out the Current Draw

When the power is 1000 kW, a 3.3 kV motor needs about 175 amps, but a 6.6 kV motor only needs 87 amps. This decrease has a big effect on the size of cables and the cost of building electricity infrastructure.

Needs for Motor Insulation

- Class F insulation for 3.3 kV circuits (rated for 155°C).

- Class H insulation for 6.6 kV circuits (rated for 180°C).

- Both choices allow the motor to run for longer periods of time in tough conditions.

Changes to the Cooling Method

- Standard air flow is provided by IC411 cooling.

- Better cooling choices to deal with high temperatures.

- How well the motor cools down affects how well the whole system works.

Rigid quality assurance processes are used in motor testing protocols to make sure that these specifications are met. Each motor is tested in many ways, such as its resistance to insulation, its ability to withstand vibrations, and its temperature performance.

3.3 kV motors are a great choice if you need cost-effective options for applications that need moderate power. 6.6 kV motor setups are very helpful for applications that need very little current infrastructure.

Application-Specific Voltage SelectionCost-Benefit Analysis and ROI Considerations

Different industrial sectors require tailored approaches to voltage selection based on operational demands and infrastructure constraints.

Manufacturing Applications

Automotive production lines utilize 3.3 kV motors for precision applications including robotic systems and assembly equipment. The voltage level provides excellent motor starter compatibility while maintaining safe operational parameters. Aerospace manufacturing benefits from the precise speed control characteristics of medium voltage systems.

Electronics manufacturing requires stable motor operation to prevent electromagnetic interference. The 3.3 kV motor configuration offers superior motor protection against voltage fluctuations that could disrupt sensitive production processes.

Process Control Systems

Water pumps in municipal treatment facilities often employ 6.6 kV motors for high-capacity applications. The reduced current requirements minimize cable costs across extensive plant layouts. Compressors in chemical processing benefit from the efficiency improvements available with higher voltage operation.

Industrial motor applications in food processing demand stringent hygiene standards. Both voltage levels accommodate IP54 protection ratings that prevent contamination while maintaining operational reliability.

HVAC and Refrigeration

Commercial HVAC systems utilize variable frequency drives with 3.3 kV motors to optimize energy consumption. The combination provides excellent motor efficiency across varying load conditions. Large-scale refrigeration facilities often benefit from 6.6 kV systems that reduce electrical infrastructure complexity.

Energy and Utilities

Power generation facilities employ both voltage levels depending on specific applications. Wind turbine systems often incorporate 3.3 kV motors for pitch control mechanisms. Water treatment plants utilize 6.6 kV motors for high-capacity pumping applications.

If you need versatile solutions for diverse manufacturing processes, then 3.3 kV motors provide excellent adaptability. Operations requiring high power output with simplified electrical systems benefit from 6.6 kV motor installations.Different types of industries need different ways to choose the right voltage based on their needs and the limitations of their equipment.

Applications in manufacturing

3.3 kV motors are used in robotic systems and assembly tools on auto production lines for precise tasks. While keeping safe operating conditions, the voltage level makes motor starters work well with it. Medium voltage devices are good for aerospace manufacturing because they can precisely control speed.

To keep electromagnetic interference from happening, motors used in electronics making must be stable. The 3.3 kV motor setup protects the motor better against voltage changes that could mess up important production processes.

Keeping an eye on processes

6.6 kV motors are often used in water pumps in local treatment plants for high-capacity tasks. Because less current is needed, cable costs are kept to a minimum across large plant plans. Working with higher voltage makes compressors more efficient, which is useful in chemical processes.

Strict hygiene standards are needed for industrial motor uses used in food processing. Both voltage levels can handle IP54 protection grades, which keep things clean while keeping the system reliable.

AC and ice machines

To get the most out of their energy use, commercial HVAC systems use variable frequency drives with 3.3 kV motors. The combination makes the motor very efficient under a wide range of load situations. 6.6 kV systems make electrical infrastructure simpler, which is good for large refrigeration centres.

Power and utilities

Facilities that make electricity use both voltage levels, based on the job. For controlling the pitch, wind turbines often have 3.3 kV motors built in. 6.6 kV motors are used in water treatment plants for high-capacity pumping tasks.

If you need flexible options for a wide range of manufacturing processes, 3.3 kV motors are a great choice. 6.6 kV motor setups are good for tasks that need a lot of power but don't need complicated electrical systems.

Economic factors play crucial roles in voltage selection decisions. Total cost of ownership extends beyond initial motor purchase price to include installation, operation, and maintenance expenses.

Initial Investment Comparison

3.3 kV motors typically require 15-20% lower initial investment compared to equivalent 6.6 kV systems. This advantage stems from simpler motor control requirements and reduced protection system complexity. However, electrical infrastructure costs may offset motor savings in high-power applications.

Operational Efficiency Metrics

Energy efficiency improvements with proper voltage selection can reduce operational costs by 8-12% annually. Motor load optimization through appropriate voltage selection directly impacts electricity consumption. Variable frequency drives enhance these savings by matching motor speed to actual demand.

Maintenance Cost Analysis

Preventive motor maintenance costs remain relatively consistent across voltage levels. However, specialized training requirements for 6.6 kV systems may increase labor expenses. Motor repair complexity increases with voltage level, affecting long-term maintenance budgets.

Infrastructure Investment

Cable sizing reductions with 6.6 kV systems can decrease infrastructure costs by 25-35% in large installations. Motor control center specifications vary significantly between voltage levels, affecting electrical room requirements. Protection system complexity increases with voltage level but offers enhanced motor protection capabilities.

Return on Investment Timeline

Typical payback periods range from 18-36 months depending on application specifics. Energy cost savings drive ROI calculations in most industrial applications. Motor efficiency improvements provide consistent returns throughout equipment lifecycle.

If you need immediate cost reduction with moderate power requirements, then 3.3 kV motors offer excellent value. Long-term operations with high power demands benefit from 6.6 kV motor investments despite higher initial costs.

XCMOTOR's 3.3 kV Motor Advantages

XCMOTOR has great performance thanks to its advanced engineering and high-quality manufacturing methods. Modern technology has been built into our medium voltage motors so they can work in tough industrial settings.

Excellence in Design

- A small structure means less installation room is needed.

- The lightweight design makes moving and mounting easier.

- Advanced motor winding methods make sure that the power density is just right.

- Precision-balanced blades keep noise and vibration to a minimum.

- Better motor insulation methods give them a longer useful life.

Advantages for performance

- Up to 15% less energy is used when motors are more efficient.

- Operating with less noise (less than 75 dB) makes the workplace better.

- Low vibration levels make bearings last longer and require less upkeep.

- Under normal working conditions, the extended service life is more than 20 years.

- Less complicated building steps cut down on the time and money needed for commissioning.

Versatility in Application

- Fans: Better control of airflow and the ability to change speeds.

- Water pumps: Easily moving fluids with different pressure needs.

- Compressors: Dependable performance during high duty cycles.

- Crushers have a high starting torque for handling heavy materials.

- Machines for cutting: Accurate speed control for use in industry.

- Transportation equipment: Strong success in mobile apps.

Help with technolog

- Experts in application engineering help choose motors.

- Options for customisation meet the specific needs of each business.

- Full warranty covering gives you peace of mind.

- There is dedicated technical help available, even on weekends.

- Options for fast delivery cut down on job delays.

XCMOTOR's 3.3 kV motors are the best deal for industrial use because they are proven to be reliable and come with full support.

Implementation Best Practices

To install a motor correctly, you need to plan ahead and pay close attention to the technical details. When implemented correctly, it works best and lasts the longest.

Planning Before Installation

When choosing a motor, it's important to keep the application's power, speed, and environmental factors in mind. Evaluating the electrical infrastructure makes sure that the power source and safety systems are working properly. Preparing a site includes designing the foundation and thinking about the surroundings.

Steps for Installation

The right way to place a motor stops vibrations from spreading and makes sure that it is aligned correctly. Electrical lines must follow the rules in your area and the manufacturer's instructions. Test the motor before turning it on to make sure the fitting is correct and the system is ready to go.

Steps for commissioning

The motor should be turned on for the first time while being watched and a light load should be applied gradually. Programming a variable frequency drive to work best in certain situations improves effectiveness. Calibration of the protection system makes sure that the motor is protected reliably in all operating situations.

Monitoring of operations

Regularly checking the performance of motors finds problems before they happen. Monitoring the temperature keeps insulation from getting damaged by heat stress. Vibration analysis finds mechanical issues early on in the creation process.

Professional implementation services will get you the best results if you need full software help using tried-and-true methods. Manufacturer-supported commissioning processes are helpful for complicated applications that need specialised knowledge.

Conclusion

When deciding between 3.3 kV and 6.6 kV motors, you need to carefully think about the needs of the application, the limitations of the equipment, and the cost. The 3.3 kV motor is very flexible and can be used for a wide range of low- to medium-power tasks. It also requires less upfront investment and less maintenance. 6.6 kV systems, on the other hand, are more complicated but work better for high-power uses. To be successful, you need to choose the right power for the job while also thinking about how much it will cost in the long run. Professional advice is needed to make sure that the motor is chosen in a way that maximises performance while minimising total ownership costs in a wide range of commercial settings.

Partner with XCMOTOR for Superior Motor Solutions

With high-quality 3.3 kV Motor options that are specifically suited to your needs, XCMOTOR is ready to help you improve your business. As a reliable manufacturer, we offer great value in manufacturing, HVAC, and energy applications by combining advanced technical knowledge with full customer support. Our technical team can help you choose the right voltage, and our quality assurance methods make sure that the product will work well. Contact our specialists at xcmotors@163.com to discuss your motor requirements and discover how our innovative solutions can enhance your operational efficiency while reducing total ownership costs.

References

1. IEEE Standard 841-2023: Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors

2. NEMA MG 1-2016: Motors and Generators Standard - Part 31, Definite Purpose Motor Applications

3. IEC 60034-1:2017: Rotating electrical machines - Rating and performance standards for industrial applications

4. Bonnett, Austin H. "Medium Voltage Motor Applications in Industrial Plants." IEEE Transactions on Industry Applications, Vol. 55, No. 3, 2019

5. Zhang, Wei et al. "Energy Efficiency Analysis of Medium Voltage Motors in Manufacturing Applications." International Journal of Electrical Power Systems, Vol. 28, No. 7, 2021

6. Industrial Motor Selection Handbook: Voltage Optimization Strategies for Process Industries, 3rd Edition, McGraw-Hill Professional, 2022