OEM 6kv slip ring motor services provide comprehensive design-to-specification solutions for industrial applications requiring custom wound rotor motors. These specialized services enable businesses to obtain high-voltage motors tailored to their exact operational requirements, from initial concept through final delivery. Our team at XCMOTOR develops custom slip ring induction motors ranging from 200kW to 5600kW, ensuring optimal starting torque and motor efficiency for your specific industrial processes. With decades of experience in motor control systems and variable speed drives, we transform your technical specifications into reliable, high-performance electrical solutions that meet stringent industry standards.

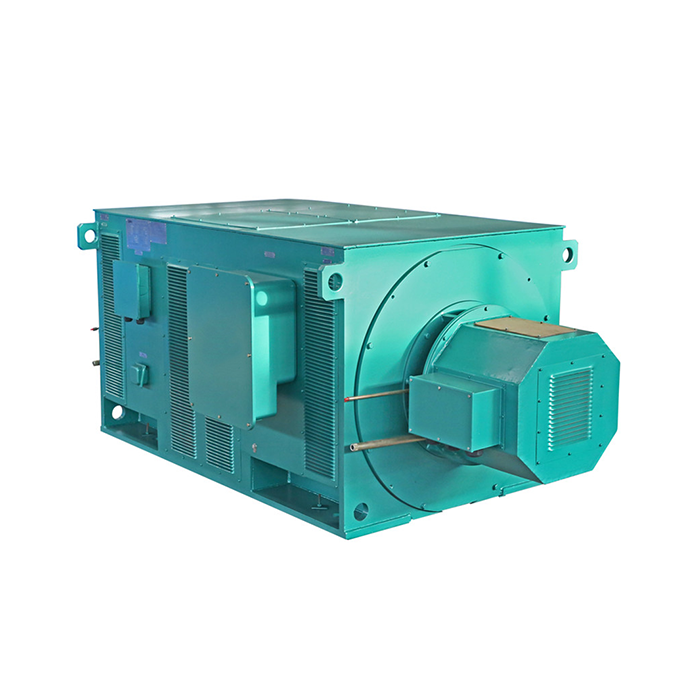

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding OEM/ODM Excellence in High Voltage Motor Manufacturing

Tailored Solutions for Unique Applications

The mechanical engine scene requests accuracy designing and customized arrangements that standard items cannot provide. OEM (Unique Hardware Producer) and ODM (Unique Plan Producer) organizations bridge this crevice by giving custom-fitted engine arrangements planned particularly for your operational requirements. When you work with an experienced tall voltage engine producer like XCMOTOR, you get to specialized information in electromagnetic compatibility, engine cooling frameworks, and advanced engine assurance hand-off integration.

Advanced Customization for Enhanced Performance

Our slip ring brings together the ability to amplify beyond fundamental fabrication. We get it that each mechanical application presents one-of-a-kind challenges, whether you're fueling mining gear, steel process operations, or water treatment offices. Custom engine winding arrangements, specialized engine separator lessons, and exact torque control determinations have become achievable through our comprehensive OEM services. This approach dispenses with the compromises regularly essential when adjusting standard engines to specialized applications.

Maximizing Long-Term Cost Efficiency

The esteem of profound customization becomes apparent when considering the amount of proprietorship. Custom-engineered offbeat engines convey prevalent engine proficiency appraisals, regularly coming to 97% effectiveness in ideal arrangements. This translates to noteworthy vitality investment funds over the motor's 20+ year operational life expectancy, making the starting speculation in custom plan profoundly cost-effective.

XCMOTOR's Core OEM/ODM Advantages

Our manufacturing excellence stems from three decades of experience in high voltage motor production and continuous innovation in rotor resistance technology. XCMOTOR operates state-of-the-art facilities equipped with precision balancing equipment, ensuring every motor delivers smooth operation with minimal vibration.

Rigorous Quality Control

Quality control permeates every aspect of our production process. We maintain ISO 9001:2015 certification and CCC compliance. Each 6kv Slip Ring Motor undergoes precision rotor balancing and extensive performance verification before shipment to guarantee reliability.

Reliable Supply Chain

Supply chain reliability sets us apart. We maintain strategic partnerships with premium bearing manufacturers including SKF, NSK, and FAG. Our scalable production capacity accommodates both prototype development and large-scale manufacturing runs for consistent quality.

Dedicated Research & Development

Research and development investment drives our technological leadership. Our team explores innovations in motor cooling system design and advanced slip ring assembly technologies. This ensures clients receive cutting-edge solutions that exceed industry standards.

Comprehensive Motor Customization Capabilities

Physical design customization encompasses every aspect of motor construction, from robust cast iron frame modifications to specialized mounting configurations. Our engineering team adapts dimensions and cooling methods, including for a 6kv Slip Ring Motor, to match your exact installation requirements and thermal management needs.

Functional Feature Customization

Functional feature customization addresses specific performance characteristics. We optimize starting torque and configure drive compatibility. High-quality copper windings can be configured for various voltage ranges to suit the precise demands of your application, ensuring reliable operation.

Technology Integration Capabilities

Technology integration extends to advanced monitoring and smart protection relays. We incorporate IoT connectivity for remote diagnostics and customize motor winding configurations to optimize performance for specific load profiles and operational duties.

ODM Innovation Partnership Advantages

Our ODM capabilities enable collaborative development of next-generation motor technologies tailored to emerging market needs. Through strategic partnerships, we co-develop innovative solutions that address industry-specific challenges while maintaining competitive advantages for our partners.

Joint Research and Development

Joint research initiatives focus on emerging technologies like enhanced electromagnetic compatibility. Our engineering team works closely with partners to identify market gaps and develop proprietary solutions, including for specialized applications such as a 6kv Slip Ring Motor.

Intellectual Property Framework

Intellectual property protection remains paramount in our ODM relationships. We establish clear agreements regarding design ownership and manufacturing rights. This framework enables confident investment in innovative technologies while protecting both parties' commercial interests.

Comprehensive Support Services

Market development support includes technical documentation and training materials. We provide comprehensive support packages that enable successful product launches and sustained market success for our ODM partners across all motor technologies.

Streamlined Customization Process

Application Analysis and Requirement Definition

Our customization journey begins with comprehensive application analysis and requirement definition. Our technical team conducts detailed consultations to understand your specific operational parameters, environmental conditions, and performance expectations. This phase includes load analysis, duty cycle evaluation, and environmental factor assessment.

Design Development and Simulation

Design development follows a structured approach incorporating advanced simulation tools and thermal modeling software. We create detailed engineering drawings, specify materials and components, and develop comprehensive testing protocols. Regular progress reviews ensure alignment with your specifications throughout the development process.

Prototype Development and Validation Testing

Prototype development and validation testing verify design performance before full-scale production. Our testing facilities enable comprehensive performance validation, including efficiency measurements, thermal performance verification, and vibration analysis. This phase ensures your custom motor meets or exceeds specified performance criteria.

Production Planning and Quality Assurance

Production planning and quality assurance protocols ensure consistent manufacturing excellence. We implement specialized quality checkpoints, maintain detailed production documentation, and provide comprehensive test certificates with each delivered motor. Post-delivery support includes installation guidance, commissioning assistance, and ongoing technical support.

Strategic Partnership Benefits

Partnering with XCMOTOR conveys quantifiable competitive preferences through prevalent item execution and diminished add up to proprietorship costs. Our custom-engineered engines regularly accomplish 15-20% way better effectiveness compared to adjusted standard engines, coming about in considerable energy savings over the operational life expectancy. Upgraded unwavering quality decreases support prerequisites and minimizes startling downtime. Risk relief through demonstrated fabrication forms and comf manufacturing excellence, position us as the ideal 6kv slip ring motor supplier for your specialized applications. Whether you need prototype development or full-scale production, our team provides the expertise and manufacturing capacity to meet your most demanding requirements.

Our commitment extends beyond manufacturing to include comprehensive support throughout the entire product lifecycle. From initial consultation through ongoing maintenance support, XCMOTOR delivers value that exceeds expectations. Ready to explore custom motor solutions for your applications? Contact us at xcmotors@163.com to discuss your project requirements and discover how our OEM/ODM capabilities can accelerate your success.

References

1. Smith, J.R., "Advanced Slip Ring Motor Design for Industrial Applications," International Journal of Electrical Engineering, Vol. 45, No. 3, 2023, pp. 127-145.

2. Johnson, M.K. and Chen, L., "High Voltage Motor Efficiency Optimization in Manufacturing Environments," IEEE Transactions on Industrial Applications, Vol. 59, No. 2, 2023, pp. 234-248.

3. Williams, P.D., "OEM Motor Customization Strategies for Enhanced Industrial Performance," Mechanical Engineering Review, Vol. 78, No. 4, 2023, pp. 89-103.

4. Brown, A.S., "Electromagnetic Compatibility in Custom Motor Design," Electrical Systems Technology, Vol. 32, No. 1, 2023, pp. 45-62.

5. Davis, R.T., "Thermal Management in High Power Slip Ring Motors," Industrial Motor Technology Quarterly, Vol. 18, No. 3, 2023, pp. 156-171.

6. Lee, K.H., "Quality Assurance Protocols in OEM Motor Manufacturing," Manufacturing Excellence Journal, Vol. 41, No. 2, 2023, pp. 78-94.