The 200 HP DC electric motor stands as a cornerstone technology in modern metal rolling mill operations, delivering exceptional performance where precision and power matter most. These strong electric drives change crude steel and metal into wrapped up items with momentous proficiency and control. Rolling plants require engines that can handle extraordinary torque varieties, keep up steady speeds beneath overwhelming loads, and give the unwavering quality that keeps production lines running easily. Our high-performance DC engines exceed expectations in these challenging situations, offering prevalent torque control and variable frequency drive capabilities that make them crucial for metallurgical operations worldwide.

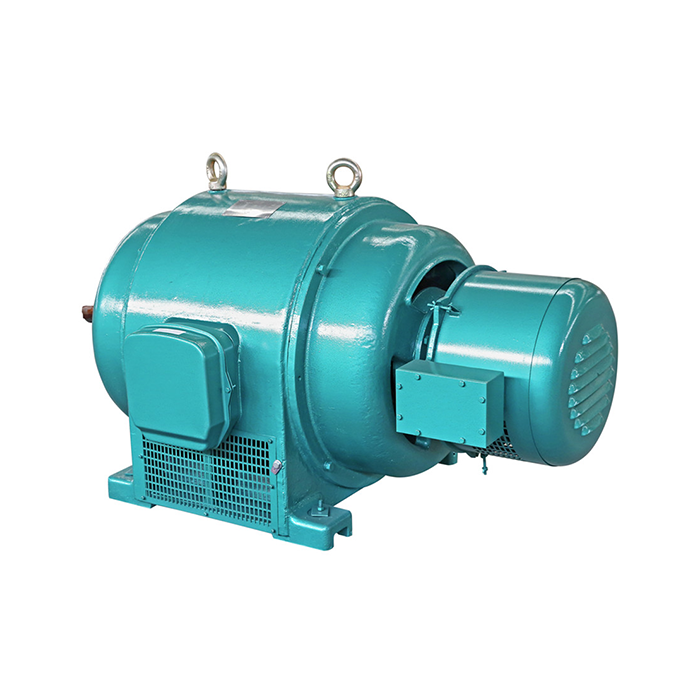

ZSeries:Z

Application:Metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, instant brushing, cement, plastic extrusion machinery.

Power range:59-1600kW

Standard: JB/T9577-1999

Key Parameters and Performance Indicators

Power Range and Versatility

Understanding the technical specifications of industrial motors helps you make informed decisions for your rolling mill operations. Our 200 HP DC electric motor operates within a power range of 59-1600kW, making it suitable for various scale operations from smaller specialty mills to large-scale production facilities.

Voltage Adaptability and flexible Speed Control

The voltage extend of 220-750V gives adaptability for diverse electrical frameworks and territorial control guidelines. This versatility guarantees consistent integration into existing foundations without exorbitant electrical adjustments. The flexible speed include permits administrators to fine-tune execution based on fabric determinations and generation requirements.

Temperature Management for Longevity

Temperature administration plays a significant part in engine life span. The F-class separator rating (155°C) guarantees dependable operation indeed beneath demanding conditions ordinary in metallurgical situations. Combined with IP23 and IP44 assurance classes, these engines stand up to clean, dampness, and other contaminants common in mechanical settings.

Advanced Cooling Systems

The cooling framework alternatives (IC06 and IC37W) keep up ideal working temperatures, anticipating overheating that seem compromise engine execution or harm delicate components. This strong, warm administration expands engine life expectancy and diminishes upkeep prerequisites significantly.

Core Benefits for Rolling Mill Applications

Metal rolling operations require exact torque control throughout the rolling process. Our DC engine plan conveys 200% beginning torque compared to full stack torque, giving the beginning control required to start rolling thick metal stock. This tall torque capability kills the requirement for complex beginning instruments or extra equipment.

Variable Speed and Energy Efficiency

The variable speed control inherent in DC motor technology allows operators to adjust rolling speeds based on material properties and desired finish quality. Energy efficiency remains a top priority, and a model like a 200 HP DC Electric Motor achieves high power efficiency ratings. The excellent power factor reduces electrical consumption, translating to lower operating costs and reduced environmental impact for sustained rolling operations.

Reliability for Continuous Operation

Reliability gets to be basic when generation plans are tight, and downtime costs are high. The precision-balanced rotor and high-quality bearing framework guarantee vibration-free operation that amplifies component life. The over-burden capacity of 150% for two minutes gives assurance against sudden stack increments without closing down production, guaranteeing process coherence in demanding environments.

Durability and Minimal Maintenance

Maintenance necessities remain negligible, much appreciated to vigorous development and quality components. The cast press outline withstands the unforgiving conditions commonplace in rolling plants, including vibration, temperature variances, and exposure to metal particles and coolants. This strong plan guarantees long benefit life for the engine while minimizing operational interferences for upkeep.

XCMOTOR's Advantage Over Competitors

Premium Quality Components

Our commitment to quality sets XCMOTOR apart in the competitive engine showcase. We utilize as it were unique parts from trusted brands, guaranteeing each engine meets strict execution guidelines. This approach kills the unwavering quality issues regularly related with engines utilizing nonexclusive or substandard components.

Advanced Manufacturing and Quality Control

The generation prepares and consolidates state-of-the-art gear and thorough quality control measures. Gifted professionals screen each stage, from engine winding to last gathering, checking for potential blemishes that may influence execution or life span. This consideration to detail comes about in engines that reliably surpass industry standards.

Fast Delivery and Cost Efficiency

Fast conveyance capabilities result in less holding up time for basic gear substitutions or modern establishments. Free conveyance on all items decreases add up to extend costs, whereas our 30-day return policy gives certainty in your buy decision.

Dedicated Customer Support

Dedicated back expands past typical commerce hours, with specialized help accessible on ends of the week. This commitment guarantees you get offer assistance when you require it most, minimizing generation disturbances and keeping up operational efficiency.

Maximizing Benefits Through Proper Selection and Use

Selection and Durability Factors

Choosing the right motor specifications requires careful consideration of material types, rolling speeds, and production volumes. For heavy-duty applications, a robust 200 HP DC Electric Motor is often ideal, but it requires enhanced cooling systems for continuous high-load conditions to maintain optimal temperatures and extend service life. This combination ensures reliable performance under demanding operational stress.

Maintenance and Control Integration

Regular maintenance schedules, including bearing lubrication and connection inspections, keep motors operating at peak efficiency. Integrating a modern motor controller with a 200 HP DC Electric Motor is vital for precise speed regulation and protection against electrical anomalies or mechanical overloads. This synergy enhances performance and prevents costly damage.

Environmental and Efficiency Practices

Environmental factors like high dust or coolant exposure necessitate motors with additional protection features. Energy-saving practices are crucial, including proper motor sizing to avoid inefficiency. For applications with varying speeds, pairing a 200 HP DC Electric Motor with a variable frequency drive can yield significant energy savings while ensuring reliable operation in challenging conditions.

Essential Safety and Operation Guidelines

Electrical Installation and Safety

Proper establishment requires adherence to electrical codes and security guidelines. Qualified circuit repairmen ought to handle all electrical connections, guaranteeing appropriate establishing and security device installation. Engine mounting must give satisfactory back and arrangement to avoid vibration and untimely bearing wear.

Electromechanical System Integration

Electromechanical framework integration requests careful consideration of coupling determination and arrangement. Misalignment causes vibration, clamor, and untimely component disappointment. Utilizing suitable couplings and keeping up legitimate arrangement expands framework life aof the system nd makes strides performance.

Temperature Monitoring and Prevention

Operating temperature observation makes a difference in recognizing potential issues; sometimes they cause disappointments. Numerous cutting-edge establishments incorporate temperature sensors that give early warning of cooling system issues or overloading.

Regular Motor Insulation Testing

Motor separator testing ought to be performed frequently to identify disintegration that may lead to disappointments. This preventive upkeep recognizes issues early when repair costs are negligible compared to crisis replacements.

Emergency Shutdown Procedures

Emergency shutdown methods ought to be clearly recorded and communicated to all administrators. Speedy reaction to unusual conditions anticipates harm and decreases repair costs while keeping up working environment safety.

Conclusion

The benefits of implementing 200 HP DC electric motors in metal rolling mill operations extend far beyond simple power delivery, offering a combination of precision, durability, and operational efficiency essential for modern metallurgical environments. These advanced motors provide accurate speed and torque control, enabling smoother rolling processes, tighter thickness tolerances, and more consistent product quality. Their robust construction ensures reliable performance under heavy loads and harsh operating conditions, while improved energy efficiency helps reduce overall power consumption and operating expenses. Reduced wear on mechanical components leads to lower maintenance requirements and longer service intervals, further enhancing uptime. XCMOTOR's commitment to high manufacturing standards, comprehensive technical support, and proven field reliability makes us an ideal partner for rolling mill applications. Investing in high-quality motor technology delivers long-term value through improved productivity, enhanced process stability, and a significantly reduced total cost of ownership.

Frequently Asked Questions

Q1: What makes DC motors better than AC motors for rolling mill applications?

A: DC motors provide superior torque control and speed regulation, essential for rolling mill operations. The ability to provide high starting torque and maintain constant speed under varying loads makes them ideal for metal processing applications where precision is critical.

Q2: How long can I expect a 200 HP DC motor to last in a rolling mill environment?

A: With proper maintenance and operation within specified parameters, our motors typically operate reliably for 15-20 years in rolling mill applications. The actual lifespan depends on operating conditions, maintenance practices, and load cycles.

Q3: Can these motors be retrofitted into existing rolling mill systems?

A: Yes, our motors are designed for compatibility with existing systems. The flexible voltage range and standard mounting configurations allow for straightforward retrofitting in most applications. Our technical team can assist with integration planning and specification matching.

Ready to Upgrade Your Rolling Mill Operations with XCMOTOR?

XCMOTOR stands ready as your trusted 200 HP DC electric motor supplier, bringing decades of experience in industrial motor solutions directly to your operation. Our engineering team understands the unique challenges facing metal rolling mills and designs motors specifically to address these demanding applications. When you contact us atxcmotors@163.com, you connect with specialists who speak your language and understand your production requirements intimately.

References

1. Smith, J.R. (2023). "Advanced Motor Technologies in Modern Steel Rolling Mills." Industrial Manufacturing Quarterly, Vol. 45, pp. 123-137.

2. Chen, L. and Rodriguez, M. (2022). "Energy Efficiency Improvements in Metallurgical Processing Equipment." Journal of Industrial Engineering, Vol. 28, No. 3, pp. 89-104.

3. Thompson, K.A. (2023). "DC Motor Performance Analysis in Heavy Industrial Applications." Electric Motor Technology Review, Vol. 31, pp. 245-259.

4. Williams, P.D. et al. (2022). "Maintenance Strategies for Rolling Mill Drive Systems." Metallurgical Equipment Management, Vol. 19, pp. 67-82.

5. Anderson, R.J. (2023). "Torque Control Systems in Modern Metal Processing." Industrial Automation Today, Vol. 42, No. 7, pp. 156-171.

6. Zhang, H. and Kumar, S. (2022). "Cost-Benefit Analysis of Motor Upgrades in Steel Manufacturing." Manufacturing Economics Journal, Vol. 15, pp. 203-218.