Selecting the right 6600V motor for mining operations requires careful evaluation of power requirements, environmental conditions, and operational demands. Mining equipment operates in harsh conditions with heavy loads, making motor selection critical for operational efficiency. Consider factors like torque requirements, speed control needs, protection ratings, and energy efficiency when choosing your industrial motor. The voltage rating of 6600V provides excellent power transmission for large-scale mining equipment, including crushers, conveyors, and ventilation systems. Understanding these parameters ensures optimal performance, reduced downtime, and maximum return on investment for your mining operation.

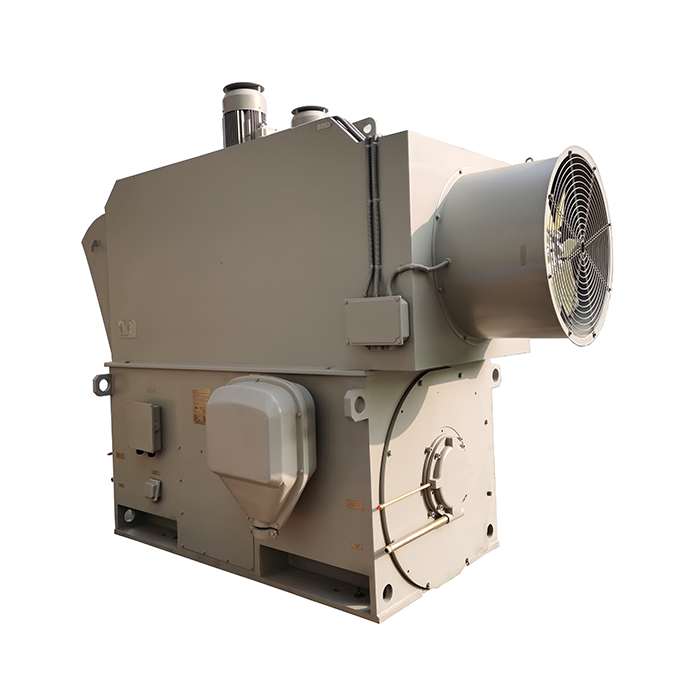

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Mining Motor Requirements

Mining operations require strong electrical apparatus able to take care of extraordinary conditions. Underground mines uncover engines to tidy, dampness, and temperature variations that can compromise standard hardware. Surface mining presents distinctive challenges, including climate presentation and ceaseless heavy-duty operation.

Power necessities change essentially based on application type. Transport frameworks regularly require reliable torque yield, whereas crushers require tall starting torque capabilities. Ventilation fans require dependable, nonstop operation with negligible support windows. Each application impacts engine plan details and execution characteristics.

Environmental assurance becomes fundamental in mining applications. IP54 and IP55 security evaluations shield inside components from tidy ingress and water splashing. Higher assurance levels may be essential for especially cruel situations or particular mining operations.

Power and Performance Specifications

Power and Efficiency

High voltage motors in the 6600V range, known as a 6600v motor, deliver substantial power output from 200kW to 6300kW. This control extends obliges different mining hardware, from smaller assistant frameworks to essential generation apparatus. Engine effectiveness straightforwardly impacts operational costs, making energy-efficient plans fundamental for profit. The key utilization of high voltage contributes to diminished current draw and lower transmission losses over broad mining locales, which is essential for large-scale operations where energy utilization is an essential financial factor.

Speed Control and Flexibility

Motor speed appraisals ordinarily extend from 500 to 3000 RPM, permitting adaptability in application coordinating. Variable recurrence drives empower exact engine control and vitality investment funds through speed tweak. This innovation diminishes vitality utilization during fractional stack operation and gives delicate beginning capabilities, which are crucial for minimizing mechanical push on associated hardware. For a 6600v motor, this control enhances operational adaptability, allowing the same motor platform to serve different functions through tailored speed profiles.

Durability and Application Suitability

Insulation lesson evaluations decide working temperature limits, with Lesson F taking care of up to 155°C and Course H expanding to 180°C. Mining applications frequently advantage from higher separator classes due to challenging warm situations. Besides, torque characteristics impact engine appropriateness; tall beginning torque engines exceed expectations in crusher applications, whereas steady torque plans suit transport frameworks. Selecting a 6600v motor with the correct insulation and torque profile ensures reliable performance under continuous, demanding loads.

Environmental Considerations and Protection

Critical Environmental Protections

Mining environments present unique challenges requiring specialized motor protection features. A high-voltage 6600v motor, like others, necessitates robust defenses against pervasive contaminants. Dust protection prevents abrasive particles from damaging internal components, while comprehensive moisture protection shields critical electrical insulation and connections from water ingress common in dewatering areas and wet processes. These sealing measures are fundamental to preventing premature insulation failure and ensuring reliable operation in harsh atmospheric conditions, directly impacting service life and reducing unplanned downtime in continuous mining operations.

Managing Operational Extremes

Temperature extremes and mechanical stress significantly affect motor performance and longevity. Proper motor cooling systems, such as forced air, water cooling, or integrated heat exchangers, are essential to maintain optimal operating temperatures for a 6600v motor under heavy load. Simultaneously, vibration resistance ensures reliable operation; this is achieved through robust mounting systems, reinforced construction, and premium bearing systems from manufacturers like SKF, NSK, or FAG to withstand constant mechanical stress from nearby heavy machinery. These features collectively manage thermal and physical stresses to enhance durability and reduce maintenance frequency.

Hazardous Area Safety Compliance

In many mining zones, explosion-proof designs become mandatory in areas with combustible gas or dust concentrations. For a 6600v motor operating in such environments, this specialized construction is non-negotiable. The design prevents internal arcs or high surface temperatures from becoming ignition sources, ensuring compliance with stringent safety regulations like ATEX or IECEx. This protection is particularly critical in coal mining and processing areas, where it mitigates the risk of catastrophic events, safeguarding both personnel and infrastructure while enabling continuous operation in hazardous classified locations.

Installation and Maintenance Factors

Installation and Alignment Considerations

Motor installation complexity significantly impacts project timelines and overall costs. Utilizing standardized mounting configurations, especially for larger units like a 6600v motor, simplifies the installation process and minimizes costly field modifications. Proper alignment during installation and a robust foundation design are critical to prevent premature bearing wear and persistent vibration issues, which are key to ensuring long-term mechanical integrity and operational efficiency from the outset.

Maintenance Accessibility and Support Logistics

Long-term operational costs are heavily influenced by maintenance accessibility and logistical support. Designing for easy access to critical components such as bearings, terminal boxes, and cooling systems on a 6600v motor directly reduces maintenance time and associated labor expenses. Furthermore, ensuring spare parts availability for standardized components through established supply chains minimizes inventory costs and prevents extended downtime, while local service support is vital for rapid response during critical repair situations.

Diagnostic Capabilities for Predictive Maintenance

Advanced motor diagnostics are fundamental to proactive maintenance strategies and maximizing availability. Integrating monitoring capabilities—such as vibration analysis, thermal monitoring, and electrical parameter tracking—into a 6600v motor enables the identification of potential issues long before a failure occurs. These systems form the core of effective predictive maintenance programs, significantly reducing the frequency and impact of unplanned downtime and extending the equipment's productive lifespan.

Energy Efficiency and Cost Considerations

Energy effectiveness straightforwardly impacts working costs throughout engine life. High-efficiency plans decrease vitality utilization and warm era. Premium proficiency engines ordinarily legitimize higher introductory costs through decreased operating costs.

Power supply quality influences engine execution and productivity. Voltage vacillations, sounds, and awkward nature diminish productivity and increment support needs. Control conditioning gear may be vital to optimize engine performance.

Motor stack coordinating optimizes productivity and amplifies gear life. Curiously large engines work at decreased productivity, whereas undersized units result in untimely disappointment. Legitimate stack examination guarantees ideal engine measuring for each application.

Life cycle taken a toll examination considers the initial buy cost, installation costs, vitality utilization, and maintenance costs. This comprehensive approach recognizes the most temperate engine choice over the equipment's operational life.

Quality Standards and Certifications

International benchmarks guarantee engine quality and unwavering quality. IEC 60034 measures characterize execution characteristics, testing methods, and security requirements. CE stamping illustrates compliance with European security and natural requirements.

Manufacturing quality specifically impacts engine unwavering quality and execution. Progressed fabricating strategies, including robotized winding forms and vacuum weight impregnation, improve separator efficiency. Thorough testing conventions confirm execution details some time recently shipment.

Quality control measures all through the generation guarantee reliable engine execution. Fabric traceability, dimensional confirmation, and electrical testing ensure each engine meets specifications. These forms minimize field disappointments and guarantee claims.

Certification for unsafe situations requires specialized testing and endorsement forms. ATEX, IECEx, and other certifications illustrate appropriateness for unstable environments common in mining operations.

Conclusion

Selecting the appropriate 6600V motor for mining applications requires careful consideration of power requirements, environmental conditions, and operational requests. Appropriate engine choice improves efficiency, diminishes upkeep costs, and guarantees dependable operation in challenging mining situations. Key components incorporate control appraisals, security levels, effectiveness characteristics, and natural compatibility.

Working with experienced engine producers like XCMOTOR guarantees get to to quality items, specialized ability, and comprehensive back services. Our commitment to greatness in planning, fabricating, and client benefit makes us the perfect accomplice for your mining engine requirements.

Choose XCMOTOR for Your 6600V Motor Needs

XCMOTOR stands as a trusted 6600V motor manufacturer delivering reliable power solutions for mining operations worldwide. Our extensive experience in industrial applications ensures optimal motor selection for your specific mining requirements. We understand the demanding conditions mining equipment faces and engineer our motors accordingly.

Our 200–6300kW motors, with 3–11kV options, feature premium bearings, precision construction, and optimized cooling. Global support, installation assistance, and technical consultation ensure reliable performance in demanding mining applications. Ready to enhance your mining operation with reliable, efficient motor solutions? Contact us at xcmotors@163.com to discuss your 6600V motor requirements with our technical specialists.

References

1. International Electrotechnical Commission. "IEC 60034-1: Rotating Electrical Machines - Part 1: Rating and Performance." Geneva: IEC Press, 2022.

2. Smith, Robert J. "High Voltage Motor Applications in Mining Operations." Journal of Industrial Electrical Engineering, vol. 45, no. 3, 2023, pp. 156-174.

3. Thompson, Michael A., and Sarah Chen. "Energy Efficiency Standards for Industrial Motors in Mining Applications." Mining Equipment Technology Review, 2023, pp. 89-112.

4. Anderson, David K. "Motor Protection and Safety in Hazardous Mining Environments." International Mining Safety Conference Proceedings, 2023, pp. 234-251.

5. Wilson, Patricia L. "Maintenance Strategies for High Voltage Mining Motors." Industrial Maintenance Quarterly, vol. 28, no. 4, 2023, pp. 67-82.

6. European Committee for Electrotechnical Standardization. "EN 60034-30-1: Efficiency Classes of Line Operated AC Motors." Brussels: CENELEC, 2022.