Planning, equipment, and safety practices are needed to install a YBX5 explosion-proof motor safely. The YBX5 explosion-proof motor is necessary for dangerous industrial applications because its rugged shell prevents internal sparks from igniting explosive atmospheres. To maximize performance and safety, proper installation requires site preparation, secure mounting, exact electrical connections, and rigorous testing.

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the YBX5 Explosion-Proof Motor

A YBX5 explosion-proof motor?

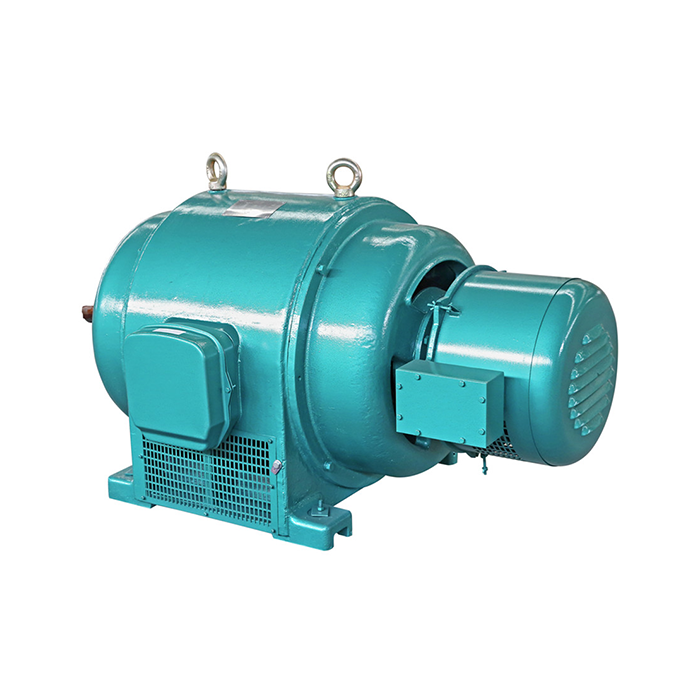

The YBX5 explosion-proof motor is a complex industrial device designed for explosive gas or combustible dust situations. This motor series runs at 380V, 660V, 415V, 380/660V, and 660/1140V with power outputs from 0.55kW to 630kW. This durable motor uses squirrel cage technology and a completely enclosed, self-fan cooling design to function well in harsh situations.

The motor's cast iron frame and end shields are strong and heat-dissipate well. This structure makes it suitable for tough handling and high-stress conditions in petroleum, chemical, mining, metallurgy, electric power, and equipment sectors. The YBX5 series maximizes energy use while meeting safety criteria with IE5 efficiency class ratings.

How Does the YBX5 Explosion-Proof Motor Work?

The YBX5 uses electromagnetic principles and enhanced safety measures to prevent explosive atmospheres from igniting. The motor's explosion-proof design has certification markings Ex d I Mb, Ex d IIB T4 Gb, and Ex d IIC T4 Gb, indicating conformity with international safety requirements for hazardous zone classifications.

Flameproof motor enclosures prevent sparks and heat from reaching combustible materials. This design keeps internal explosions contained and flames from spreading. With ambient temperature ratings from -20°C to +40°C and altitude capabilities up to 1000m above sea level, the innovative cooling system provides ideal temperature management over lengthy operating durations.

Installation Preparation

Tools Required

Specialized tools and safety gear are needed to install explosion-proof motors. Preparation affects installation quality and motor performance.

Precision torque wrenches calibrated for bolt requirements, digital multimeters for electrical verification, shaft alignment tools, and lifting equipment for motors weighing several hundred kilos are essential. Safety equipment includes explosion-rated flashlights, insulation gloves for the working voltage, safety glasses, hard helmets, and grounding straps to avoid static discharge in hazardous areas.

Extras include explosion-proof cable glands, flexible conduits for dangerous situations, and correctly certified electrical connections. These tools are easily accessible to save installation delays and promote safety.

Site Prep

Safe motor installation in explosive environments starts with environmental evaluation. To achieve zone classification and ventilation compliance, the installation location must be thoroughly evaluated.

Site preparation includes assuring foundation strength to sustain the motor's weight and operating stresses, electrical supply characteristics that meet motor specifications, and maintenance access. The installation area needs grounding, fire suppression, and operator-accessible emergency shutdown.

Air circulation is assessed to avoid explosive gasses and dust from accumulating. Moisture, corrosive chemicals, and high temperatures may damage motor performance and safety systems, thus the site must protect them.

Installing the YBX5 Explosion-Proof Motor

Instructions for Installation

Installation requires precise care and safety standards. To maximize YBX5 explosion-proof motor performance and safety, each stage builds on the last.

Installing starts with foundation preparation and motor placement. Level, stable, and able to absorb operating vibrations without compromising structural integrity are foundation requirements. Motor installation requires tightening bolts to manufacturer standards, usually 200–400 Nm depending on motor size and mounting type.

Cable routing, termination, and phase sequence verification are crucial to electrical connection. Installation of cable glands must be explosion-proof to provide seal and strain relief. All electrical connections are tested for insulation resistance using a 500V megohmmeter. Readings above 10 indicate good insulation.

System integration tests verify control circuit performance, emergency stop systems, and protective relay settings to complete installation. Documentation is provided for maintenance and regulatory compliance at each connection point.

Testing/Verification

Motor performance and safety system operation are tested after installation. This crucial step detects faults and guarantees regulatory compliance before operational deployment.

First-stage testing includes rotation direction verification, no-load current measurement, and precision instrument vibration analysis. Proper alignment and mounting integrity are indicated by vibration levels below 2.8 mm/s RMS for motors in this power range. Temperature monitoring at startup checks cooling system performance and thermal concerns.

Performance verification includes power factor measurement, efficiency validation, and load testing under simulated operating settings. These tests verify that the motor satisfies performance standards within acceptable temperature and vibration limitations. Recording all test results helps plan maintenance and track performance.

Repairs and Issues

Regular Maintenance Tips

Motor lifetime and safety in explosive environments are greatly extended by preventive maintenance programs. Critical components that affect safety and performance are regularly maintained.

Monthly visual checks of the motor housing for cracks or corrosion, quarterly bearing lubrication with high-temperature greases, and semi-annual insulation resistance and connection integrity testing are standard maintenance plans. The YBX5 series may be customized for individual application and maintenance needs using SKF, NSK, and FAG bearings.

Cleaning removes dust and debris that might reduce cooling performance or cause explosions. These tasks need non-sparking instruments and hazardous area-approved cleaning solutions. Regular maintenance includes explosion-proof enclosure integrity checks and gasket or seal replacement to maintain motor safety certification.

Common Issues and Solutions

Explosion-proof motors demand electrical and safety expertise to troubleshoot. Overheating, vibration, noise, and electrical abnormalities may signal difficulties.

Overheating may come from poor ventilation, high load, or bearing wear that increases friction losses. Solutions include thermal imaging or vibration analysis for airflow verification, load analysis, and bearing examination. Electrical difficulties can result from connection loosening owing to heat cycling or insulation contamination.

Safety system failures, structural damage to explosion-proof enclosures, and electrical problems that might jeopardize the motor's explosion-proof rating need professional help. Repairing without certification and equipment might violate safety approvals and cause hazards.

Brand and Product Information

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., known as XCMOTOR, provides power equipment solutions to industries worldwide. Beyond manufacturing, we provide total client support throughout the equipment lifespan, from first consultation to technical help.

ATEX and CCC-certified explosion-proof motors are made by XCMOTOR to strict quality standards. We have decades of hazardous area installation experience in petroleum, chemical, mining, and utility industries. Innovation drives motor design, efficiency, and safety improvements at the organization.

XCMOTOR's YBX5 motor series meets different industrial needs with a wide variety of power outputs and voltage settings. Our product selection may be customized for individual applications to optimize performance under unique operating situations.XCMOTOR offers warranty coverage, installation instructions, maintenance training, and troubleshooting. We provide speedy shipping, 30-day returns, and 24/7 assistance to satisfy our customers.

Conclusion

Installing a YBX5 explosion-proof motor safely and efficiently requires careful preparation, proper tools, and adherence to established procedures. The installation process encompasses site assessment, precise mounting techniques, electrical connections, and thorough testing to ensure optimal performance and safety compliance. Regular maintenance and proper troubleshooting extend motor lifespan while maintaining the safety certifications essential for hazardous area operations. XCMOTOR's comprehensive support services and quality products provide the foundation for successful installations across diverse industrial applications.

Frequently Asked Questions

Q1: What are the key benefits of using a YBX5 explosion-proof motor?

A: YBX5 motors offer exceptional safety in hazardous environments, combining IE5 efficiency ratings with robust explosion-proof construction. The fully enclosed, self-fan cooling design ensures reliable operation across temperature ranges from -20°C to +40°C while maintaining optimal performance. These motors provide long-term reliability with minimal maintenance requirements, making them cost-effective solutions for critical industrial applications.

Q2: How does proper installation affect motor performance and safety?

A: Correct installation directly impacts both operational efficiency and safety compliance. Proper mounting eliminates excessive vibration that could damage internal components or compromise explosion-proof enclosures. Accurate electrical connections ensure optimal power delivery while maintaining insulation integrity required for hazardous area certification. Following installation procedures preserves warranty coverage and regulatory approvals necessary for legal operation.

Q3: What maintenance intervals are recommended for YBX5 motors in continuous operation?

A: Continuous operation requires monthly visual inspections, quarterly bearing maintenance, and semi-annual electrical testing. Bearing lubrication schedules depend on operating conditions but typically range from 2000-6000 operating hours. High-stress environments or extreme temperatures may require more frequent maintenance intervals. Documentation of all maintenance activities supports warranty claims and regulatory compliance requirements.

Choose XCMOTOR for Your Explosion-Proof Motor Requirements

XCMOTOR stands as your trusted YBX5 explosion-proof motor supplier, combining decades of engineering expertise with comprehensive customer support services. Our commitment to quality ensures every motor meets rigorous safety standards while delivering exceptional performance in your critical applications.

Whether you need a single motor replacement or complete system upgrades, XCMOTOR provides customized solutions tailored to your specific operational requirements. Our technical team offers installation support, maintenance training, and ongoing troubleshooting assistance to maximize your equipment investment. We maintain extensive inventory to ensure fast delivery of standard configurations while offering customization options for specialized applications.

Experience the difference that quality engineering and dedicated support make in your operations. Contact us at xcmotors@163.com to discuss your explosion-proof motor needs with our technical specialists.

References

1. National Electrical Manufacturers Association. "Guide for Explosion-Proof Motor Installation and Maintenance in Hazardous Locations." NEMA Standards Publication MG-2, 2019.

2. International Electrotechnical Commission. "Equipment for Explosive Atmospheres - Part 1: Equipment Protection by Flameproof Enclosures." IEC 60079-1 Standard, 2020.

3. American Petroleum Institute. "Electrical Apparatus for Use in Class I Hazardous Locations - Motors." API Recommended Practice 500, 2018.

4. Institute of Electrical and Electronics Engineers. "Installation and Maintenance Practices for Industrial Motor Systems in Explosive Atmospheres." IEEE Industry Applications Society Conference Proceedings, 2021.

5. Occupational Safety and Health Administration. "Electrical Safety Requirements for Hazardous Location Equipment Installation." OSHA Technical Manual Section IV Chapter 4, 2020.

6. European Committee for Standardization. "ATEX Directive Implementation Guidelines for Explosion-Proof Motor Installation." EN 60079 Series Standards Commentary, 2019.