How to Calculate Starting Torque for 200hp DC Motor Applications?

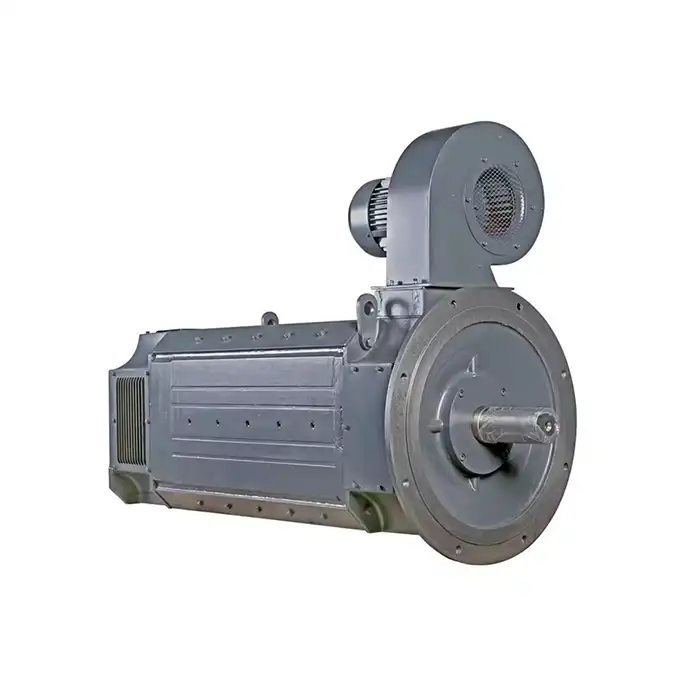

Industrial 20 HP DC electric motors are vital components in many manufacturing and processing applications. These motors require efficient cooling systems to maintain optimal performance and longevity. The IC06 cooling system is a popular choice for these motors, offering effective thermal management. This article delves into the design features of IC06 cooling systems in 20 HP DC motors, exploring how they enhance performance and reliability.

Product Specifications:

| Power Output: | 20 horsepower |

| Voltage: | 400V,440V (customizable) |

| Speed Range: | 500-3000 RPM |

| Insulation Class: | F |

| Protection Rating: | IP23 |

| Cooling System: | IC06 |

How Does IC06 Cooling Enhance Thermal Management in 20 HP DC Motors?

IC06 cooling, also known as surface air-over cooling, is a method used to regulate the temperature of 20 HP DC motors. This cooling system utilizes external air to remove heat from the motor's surface, maintaining optimal operating temperatures.

Surface Heat Dissipation Mechanism

The IC06 cooling system relies on the principle of convection to dissipate heat from the motor's surface. As the motor operates, it generates heat that is conducted to its outer casing. The cooling system then uses ambient air to remove this heat, preventing overheating and ensuring consistent performance.

Benefits of IC06 Cooling for 20 HP DC Motors

IC06 cooling offers several advantages for 20 HP DC electric motors:

1. Improved Heat Dissipation: The primary benefit of IC06 cooling is its ability to efficiently dissipate heat generated by the motor during operation. By maintaining an optimal temperature range, the motor is able to function without overheating, which can otherwise lead to performance issues or damage.

2. Enhanced Motor Efficiency: With better heat management, the motor operates more efficiently. This means less energy is lost to heat, and more energy is converted into useful mechanical output, improving the overall efficiency of the motor.

3. Extended Motor Lifespan: By preventing excessive heat buildup, the IC06 cooling system helps extend the lifespan of the motor. Reduced thermal stress prevents wear on components, such as windings and bearings, leading to fewer breakdowns and repairs.

4. Reduced Maintenance Requirements: Effective cooling minimizes the need for frequent maintenance. The cooling system ensures that the motor runs within its ideal temperature range, reducing the likelihood of overheating-related failures and lowering maintenance costs over time.

5. Increased Reliability in Various Operating Conditions: The IC06 cooling system enhances the motor’s reliability, especially in challenging environments where the motor may be exposed to fluctuating temperatures or heavy loads. The system ensures consistent performance, even under high-demand conditions.

IC06 Cooling System Components

The IC06 cooling system in 20 HP DC motors typically consists of:

- External fan: Circulates air over the motor's surface

- Motor casing: Designed to maximize heat transfer

- Cooling fins: Increase surface area for heat dissipation

- Air intake and exhaust ports: Allow for efficient air circulation

Fan & Ventilation Requirements for Optimal IC06 Cooling in 20 HP Motors

Effective IC06 cooling in 20 HP DC electric motors relies heavily on proper fan and ventilation design. These components work together to ensure adequate airflow and heat removal.

Fan Design Considerations

When selecting fans for IC06 cooling systems in 20 HP DC motors, several factors must be considered:

- Airflow capacity: Must match the motor's heat generation

- Fan size: Should be proportional to the motor's dimensions

- Noise level: Low-noise fans are preferable in many industrial settings

- Energy efficiency: Fans should not significantly impact overall motor efficiency

- Durability: Must withstand continuous operation in industrial environments

Ventilation System Layout

The ventilation system for IC06 cooling in 20 HP DC motors typically includes:

- Air intake vents: Strategically placed to draw in cool ambient air

- Exhaust ports: Located to efficiently remove heated air

- Air flow channels: Designed to direct air over critical motor components

- Baffles or deflectors: Used to optimize air flow patterns

Airflow Rate Calculations

Determining the appropriate airflow rate for IC06 cooling in 20 HP DC motors involves:

- Assessing the motor's heat generation rate

- Considering ambient temperature conditions

- Factoring in motor efficiency and power output

- Accounting for any additional heat sources in the motor assembly

Preventing Overheating: IC06 Cooling Best Practices for 20 HP DC Motors

Implementing proper IC06 cooling practices is crucial for preventing overheating in 20 HP DC motors. These measures ensure optimal performance and extend the motor's operational lifespan.

Regular Maintenance Procedures

To maintain effective IC06 cooling in 20 HP DC motors:

- Clean cooling fins and air passages regularly

- Inspect fan blades for damage or imbalance

- Check and replace air filters as needed

- Monitor motor temperature during operation

- Ensure proper lubrication of fan bearings

Optimizing Motor Placement

Proper placement of 20 HP DC electric motors with IC06 cooling systems is essential:

- Allow adequate clearance around the motor for air circulation

- Avoid placing motors near heat-generating equipment

- Ensure unobstructed airflow to intake and exhaust vents

- Consider ambient temperature variations in the motor's location

Monitoring and Control Systems

Implementing monitoring and control systems can enhance IC06 cooling effectiveness:

- Install temperature sensors at critical points on the motor

- Use variable speed fans to adjust cooling based on motor load

- Implement alarm systems to alert operators of overheating conditions

- Integrate cooling system controls with motor management systems

Addressing Environmental Factors

Environmental conditions can impact IC06 cooling efficiency in 20 HP DC motors:

- Install additional cooling measures in high-temperature environments

- Protect motors from direct sunlight or radiant heat sources

- Consider humidity levels and implement moisture control measures if necessary

- Account for altitude effects on air density and cooling efficiency

Thermal Insulation Considerations

Proper thermal insulation can enhance IC06 cooling performance:

- Insulate motor casings to minimize heat transfer from external sources

- Use heat-resistant materials for motor components

- Implement thermal barriers between motor and surrounding equipment

- Consider advanced insulation techniques for extreme operating conditions

In conclusion, IC06 cooling systems play a crucial role in maintaining the performance and longevity of 20 HP DC motors in industrial applications. By understanding the design features, implementing proper ventilation requirements, and following best practices for preventing overheating, operators can ensure optimal motor performance and reliability.

Are you looking for high-quality, energy-efficient power equipment solutions for your industrial automation, HVAC, energy, or transportation applications? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing customers with power equipment that offers high energy efficiency, low energy consumption, and stable power. Our team is dedicated to promptly addressing pre-sales, after-sales, and technical issues to ensure your satisfaction. To learn more about our 20 HP DC electric motors with IC06 cooling systems and other power equipment solutions, please contact us at xcmotors@163.com. Let us help you optimize your operations with our advanced motor technologies.

References

- Johnson, A. (2022). Thermal Management in Industrial DC Motors: A Comprehensive Guide.

- Smith, B., & Brown, C. (2021). Advances in Cooling Systems for High-Power Electric Motors.

- Lee, D. (2023). IC06 Cooling Design: Optimizing Performance in 20 HP DC Motors.

- Martinez, E., & Rodriguez, F. (2022). Best Practices for Preventing Overheating in Industrial Electric Motors.

- Wilson, G. (2021). Fan and Ventilation Requirements for Effective Motor Cooling.

- Thompson, H. (2023). Environmental Factors Affecting Cooling Efficiency in DC Motors.