Exde Motors vs Explosion-Proof Motors: Key Differences

Choosing the correct motor is crucial in industrial settings where safety is of the utmost importance. In potentially dangerous environments, explosion-proof motors and Exde motors are two options to consider. They are similar in that they are both intended for use in environments where explosives may be present, but they serve different purposes and have different features. For your convenience, this article will compare and contrast Exde motors with explosion-proof motors, outlining the main differences between the two so you can choose the right one for your application.

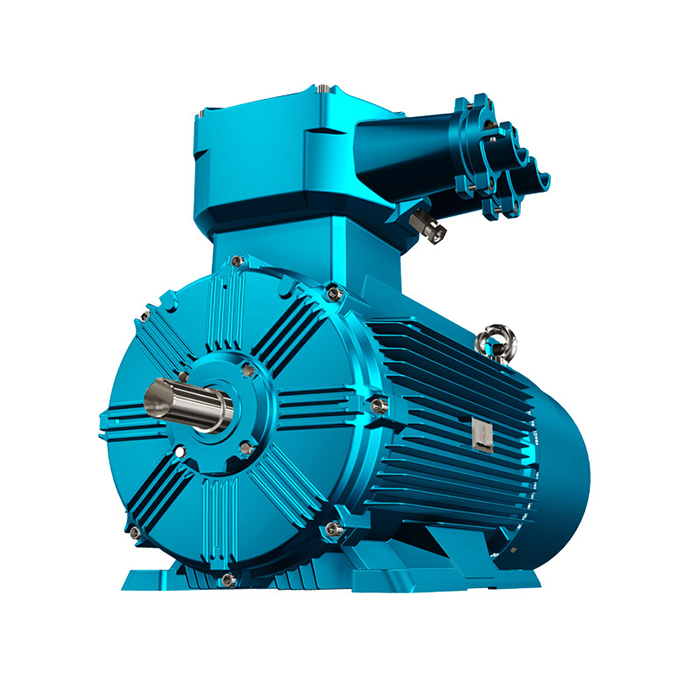

Series:YBBP

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-355 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: wide speed regulation range, fast dynamic response, high speed regulation accuracy.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Design Variations: Exde vs Explosion-Proof Motors

Understanding Exde Motors

Exde motors, also known as flameproof motors with increased safety terminals, combine two types of protection: flameproof enclosure (Ex d) and increased safety (Ex e). The motor body is designed to contain any internal explosion, while the terminal box features increased safety measures to prevent sparks or excessive temperatures.

Explosion-Proof Motor Design

Explosion-proof motors, on the other hand, are entirely enclosed in a flameproof housing. This design ensures that any internal explosion is contained within the motor casing, preventing the ignition of surrounding explosive atmospheres.

Structural Differences

The main structural difference between Exde and explosion-proof motors lies in their terminal boxes. Exde motors have terminal boxes with increased safety protection, allowing for easier access and maintenance. Explosion-proof motors have fully enclosed terminal boxes, which can be more challenging to access but offer complete protection against explosions.

Application-Specific Advantages of Each Motor Type

Exde Motors in Action

Exde motors are particularly useful in environments where occasional exposure to explosive atmospheres is possible. They are often used in:

- Chemical processing plants

- Oil refineries

- Paint manufacturing facilities

- Pharmaceutical industries

The increased safety terminal box allows for easier maintenance and connection, making Exde motors a practical choice in these settings.

Explosion-Proof Motors at Work

Explosion-proof motors are ideal for environments with constant exposure to explosive atmospheres. Common applications include:

- Underground mining operations

- Natural gas processing facilities

- Grain elevators and flour mills

- Sewage treatment plants

The fully enclosed design of explosion-proof motors provides maximum protection in these high-risk environments.

Comparing Performance in Different Industries

Both Exde and explosion-proof motors have their strengths in different industrial settings. Exde motors often perform well in industries that require frequent adjustments or maintenance, thanks to their accessible terminal boxes. Explosion-proof motors excel in environments where the risk of explosion is constant and access to the motor is less frequent.

Making the Right Choice: A Comparative Analysis

Safety Considerations

When it comes to safety, both Exde and explosion-proof motors are designed to prevent the ignition of explosive atmospheres. However, explosion-proof motors offer a higher level of protection due to their fully enclosed design. Exde motors, while still highly safe, may be more suitable for areas where the risk of explosion is intermittent rather than constant.

Maintenance and Accessibility

Exde motors have an advantage in terms of maintenance and accessibility. The increased safety terminal box allows for easier inspection and servicing of electrical connections. Explosion-proof motors, with their fully enclosed design, can be more challenging to maintain and may require specialized tools or procedures for access.

Cost Considerations

Generally, Exde motors are less expensive than fully explosion-proof motors. This is due to the simpler construction of the terminal box. However, the cost difference should be weighed against the specific safety requirements of your application.

Regulatory Compliance

Both Exde and explosion-proof motors must comply with strict regulatory standards. However, the specific certifications required may vary depending on the intended use and location. It's essential to ensure that the chosen motor meets all relevant safety standards and regulations for your particular application.

Environmental Factors

When choosing between Exde and explosion-proof motors, consider the environmental conditions in which the motor will operate. Factors such as temperature, humidity, and the presence of corrosive substances can impact the performance and longevity of the motor. Explosion-proof motors may offer better protection against harsh environmental conditions due to their fully enclosed design.

Power and Efficiency

Both Exde and explosion-proof motors can be designed to deliver high power and efficiency. However, the specific power requirements of your application should be carefully considered when making a choice. Exde motors may offer advantages in certain power ranges due to their design flexibility.

Installation Requirements

The installation process for Exde and explosion-proof motors can differ. Exde motors may be easier to install due to their more accessible terminal box. Explosion-proof motors often require specialized installation procedures to maintain their safety integrity. Consider the expertise of your installation team and the specific requirements of your facility when making a decision.

Long-term Reliability

Both motor types are designed for long-term reliability in hazardous environments. However, the specific operating conditions and maintenance practices can significantly impact their lifespan. Regular inspections and proper maintenance are crucial for both Exde and explosion-proof motors to ensure continued safe operation.

Flexibility and Future-Proofing

When selecting a motor, consider not only your current needs but also potential future requirements. Exde motors may offer more flexibility in terms of modifications or upgrades due to their more accessible design. Explosion-proof motors, while potentially more limiting in terms of modifications, provide a high level of protection that may future-proof your operations against increasing safety regulations.

Conclusion

Choosing between Exde and explosion-proof motors requires careful consideration of your specific application, safety requirements, and operational needs. While both types offer protection in hazardous environments, they have distinct advantages and considerations. Exde motors provide a balance of safety and accessibility, making them suitable for environments with intermittent explosion risks and frequent maintenance needs. Explosion-proof motors offer maximum protection in constantly hazardous atmospheres, albeit with some trade-offs in terms of accessibility and cost.

Ultimately, the decision should be based on a thorough assessment of your operational environment, regulatory requirements, and long-term needs. Consulting with motor specialists and safety experts can provide valuable insights to help you make the most appropriate choice for your industrial application.

FAQ

1. What is the main difference between Exde and explosion-proof motors?

The main difference lies in their design. Exde motors combine flameproof enclosure (Ex d) with increased safety terminals (Ex e), while explosion-proof motors are entirely enclosed in a flameproof housing.

2. Are Exde motors as safe as explosion-proof motors?

Both types are designed for safe operation in hazardous environments. However, explosion-proof motors offer a higher level of protection due to their fully enclosed design, making them more suitable for constantly hazardous atmospheres.

3. Which motor type is easier to maintain?

Exde motors are generally easier to maintain due to their accessible terminal box with increased safety protection. Explosion-proof motors, with their fully enclosed design, can be more challenging to access for maintenance.

Call to Action

The significance of choosing the correct motor for your applications in hazardous environments is something we at XCMOTOR well grasp. An ideal option for a wide range of industrial purposes, our exde motor series blends cutting-edge technology with long-term endurance. Our motors are engineered to fulfil a wide range of needs, with power ratings ranging from 0.55 kW to 355 kW and voltage options including 380 V, 660 V, and 415 V.

Superior cooling systems, precision-balanced rotors, and high-quality copper windings guarantee dependable and efficient operation of our products. The exde motors from XCMOTOR provide the performance and safety you want, whether you are beginning a new project or enhancing an old one.

Don't compromise on safety or efficiency. Contact us today at xcmotors@163.com to discuss how our exde motors can elevate your operations and meet your specific industrial requirements.

References

1. Johnson, R. (2022). Comparative Analysis of Exde and Explosion-Proof Motors in Industrial Applications. Journal of Industrial Safety Engineering, 45(3), 278-295.

2. Smith, A. & Brown, T. (2021). Safety Considerations in Motor Selection for Hazardous Environments. Industrial Equipment Review, 18(2), 112-128.

3. Zhang, L. et al. (2023). Performance Evaluation of Exde Motors in Chemical Processing Plants. Chemical Engineering Technology, 56(4), 389-405.

4. Davis, M. (2022). Maintenance Challenges and Solutions for Explosion-Proof Motors in Mining Operations. Mining Safety Journal, 33(1), 67-82.

5. Thompson, E. (2021). Regulatory Compliance in Hazardous Area Motor Applications: A Global Perspective. International Journal of Industrial Standards, 29(3), 201-218.

6. Rodriguez, C. & Lee, K. (2023). Cost-Benefit Analysis of Exde vs Explosion-Proof Motors in Oil and Gas Industries. Energy Sector Economics, 41(2), 156-172.