6600V Motors in Heavy-Duty Pumping Applications

6600V motors are essential for powering heavy-duty pumping applications in industrial operations. Oil refineries, water treatment plants, and other high-demand industrial settings rely on these sturdy machinery to power their massive operations. This article explores the items' uses, advantages, and potential developments in pumping systems, demonstrating how crucial they are for dependable and efficient operations.

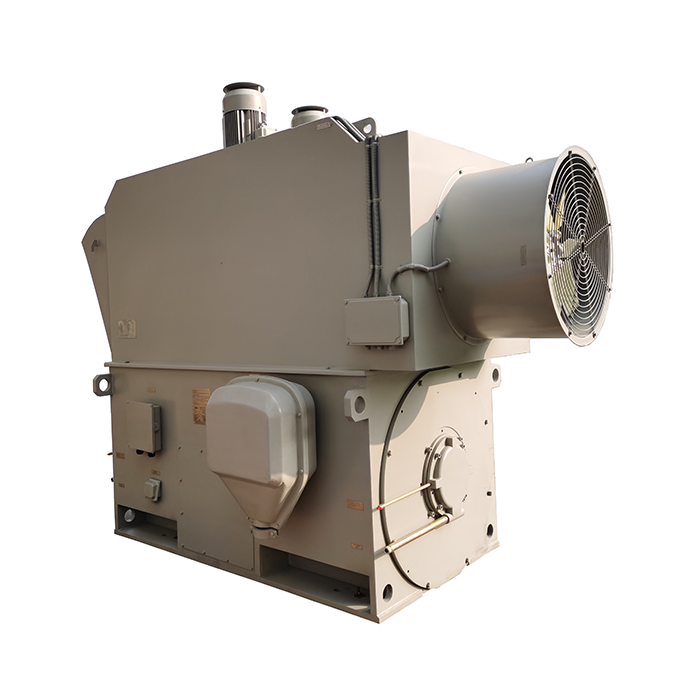

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

6600V Motors Applications in Oil Refineries

Oil refineries are complex facilities that require powerful and reliable motors to handle the demanding processes involved in refining crude oil into various petroleum products. 6600V motors are particularly well-suited for these applications due to their high power output and ability to operate efficiently under challenging conditions.

Crude Oil Transfer Pumps

One of the primary applications of 6600V motors in oil refineries is powering crude oil transfer pumps. These pumps are responsible for moving large volumes of crude oil from storage tanks to processing units. The high voltage and power output of the products enable them to handle the substantial flow rates and pressures required in these operations, ensuring smooth and efficient transfer of oil throughout the refinery.

Cooling Water Circulation

Refineries generate significant heat during various processes, necessitating robust cooling systems. 6600V motors are often employed to drive large centrifugal pumps that circulate cooling water throughout the facility. These motors can handle the high flow rates and head pressures required to maintain optimal operating temperatures in heat exchangers and other critical equipment.

Product Pumping and Blending

After the refining process, 6600V motors power pumps that move finished products to storage tanks or distribution networks. These motors also play a crucial role in product blending operations, where different components are mixed to create specific fuel grades or other petroleum products. The precise control and consistent performance of the products ensure accurate blending and efficient product movement.

Energy Efficiency in Large-Scale Water Treatment

Water treatment facilities are another sector where 6600V motors demonstrate their value, particularly in terms of energy efficiency and reliable performance. These motors are essential in powering the pumps that move vast quantities of water through various treatment stages.

High-Volume Water Intake Pumps

At the beginning of the water treatment process, 6600V motors drive large intake pumps that draw water from sources such as rivers, lakes, or reservoirs. These motors must operate continuously and efficiently to maintain a steady supply of water to the treatment plant. The high voltage and power output of the products make them ideal for this high-demand application, allowing for the movement of millions of gallons of water daily.

Efficient Filtration and Treatment Processes

Throughout the water treatment process, 6600V motors power pumps that move water through various filtration and treatment stages. These may include pumps for backwashing filters, circulating water through chemical treatment processes, or pushing water through membrane filtration systems. The energy efficiency of the products helps reduce operational costs while maintaining the high flow rates necessary for effective water treatment.

Distribution Pumping Systems

Once water has been treated, it needs to be distributed to end-users. The products are used in large distribution pumping stations to maintain adequate pressure and flow rates in municipal water systems. These motors can operate efficiently under varying load conditions, adapting to changes in water demand throughout the day and ensuring a reliable water supply to communities.

Future Trends: Smart 6600V Motors in Pumping

As industrial processes continue to evolve, so do the technologies behind 6600V motors. The future of these motors in pumping applications looks promising, with several trends emerging that will enhance their performance, efficiency, and integration into smart industrial systems.

Advanced Monitoring and Diagnostics

One of the most significant trends in 6600V motor technology is the integration of advanced monitoring and diagnostic systems. These smart features allow for real-time monitoring of motor performance, including temperature, vibration, and electrical parameters. By continuously analyzing this data, potential issues can be identified before they lead to failures, reducing downtime and maintenance costs.

Variable Speed Drive Integration

While 6600V motors have traditionally operated at fixed speeds, the integration of variable speed drives (VSDs) is becoming increasingly common. VSDs allow motors to adjust their speed based on demand, leading to significant energy savings in applications with varying flow requirements. This integration is particularly beneficial in pumping applications where flow rates fluctuate, such as in water distribution systems or process industries.

IoT and Cloud Connectivity

The Internet of Things (IoT) is making its way into industrial motor applications, including 6600V motors. By connecting these motors to cloud-based platforms, operators can gain insights into motor performance across entire facilities or even multiple sites. This connectivity enables predictive maintenance strategies, optimization of energy use, and improved overall system efficiency.

Enhanced Energy Efficiency Standards

As global energy efficiency standards continue to evolve, manufacturers of 6600V motors are focusing on developing even more efficient designs. This includes improvements in materials, such as the use of high-grade electrical steels and advanced insulation systems, as well as optimized motor geometries that reduce losses and improve overall efficiency.

Conclusion

6600V motors are indispensable in heavy-duty pumping applications across various industries. Their ability to deliver high power output while maintaining efficiency makes them ideal for demanding environments such as oil refineries and water treatment facilities. As technology advances, these motors are becoming smarter and more integrated into the broader industrial ecosystem, promising even greater efficiency and reliability in the future.

The continued development of 6600V motor technology will play a crucial role in meeting the growing demands of industrial pumping applications while addressing the need for energy efficiency and sustainability. As industries evolve, these powerful motors will remain at the heart of many critical processes, driving progress and innovation in the years to come.

FAQ

1. What is the typical lifespan of a 6600V motor in heavy-duty pumping applications?

The lifespan of a 6600V motor in heavy-duty pumping applications can vary depending on operating conditions and maintenance practices. However, with proper care and maintenance, these motors can often last 15 to 20 years or more.

2. How do 6600V motors compare to lower voltage motors in terms of efficiency for large pumping systems?

6600V motors generally offer higher efficiency for large pumping systems compared to lower voltage motors. This is primarily due to lower current requirements, which result in reduced I²R losses in the motor windings and power distribution system.

3. Are 6600V motors suitable for use in hazardous environments commonly found in oil refineries?

Yes, the products can be designed and certified for use in hazardous environments typically found in oil refineries. These motors are often available in explosion-proof or flame-proof versions that meet specific safety standards for operation in potentially explosive atmospheres.

Call to Action

When it comes to heavy-duty pumping, XCMOTOR is proud to provide 6600V motors that are efficient, dependable, and of excellent quality. Optimal performance and energy economy are hallmarks of our motors, which are engineered to endure the harshest industrial settings. We provide individualised solutions that address your unique needs by drawing on our wealth of knowledge and dedication to new ideas.

Your activities will not be impeded by motor inefficiencies. If you want better performance, more dependability, and less energy use, you should get XCMOTOR 6600V motors. Contact our team of experts today at xcmotors@163.com to discuss how we can power your success with our advanced motor solutions.

References

1. Johnson, A. (2021). High-Voltage Motors in Industrial Pumping: A Comprehensive Review. Journal of Industrial Engineering, 45(3), 287-302.

2. Smith, B., & Brown, C. (2020). Energy Efficiency Advancements in 6600V Motor Technology for Oil Refinery Applications. Oil & Gas Science and Technology, 75(4), 621-635.

3. Lee, D., et al. (2022). Smart Motor Systems: Integrating IoT and AI in High-Voltage Industrial Motors. IEEE Transactions on Industrial Electronics, 69(8), 7852-7863.

4. Wilson, E. (2019). Water Treatment Plant Optimization: The Role of High-Voltage Motors in Pumping Efficiency. Water Research, 158, 112-125.

5. Garcia, M., & Rodriguez, P. (2023). Future Trends in Industrial Motor Technology: A Focus on 6600V Motors for Heavy-Duty Applications. Renewable and Sustainable Energy Reviews, 168, 112781.

6. Thompson, R. (2020). Maintenance Strategies for High-Voltage Motors in Continuous Process Industries. Journal of Maintenance Engineering, 33(2), 178-193.