Custom Inverter Duty Induction Motor Solutions: You must know

Specialized motor solutions are in high demand due to the dynamic nature of today's industrial environment. With their individualized performance and efficiency, custom inverter duty induction motors have become an essential part of many applications. Experts and decision-makers in the field will find this exhaustive reference on bespoke inverter duty induction motor solutions very useful.

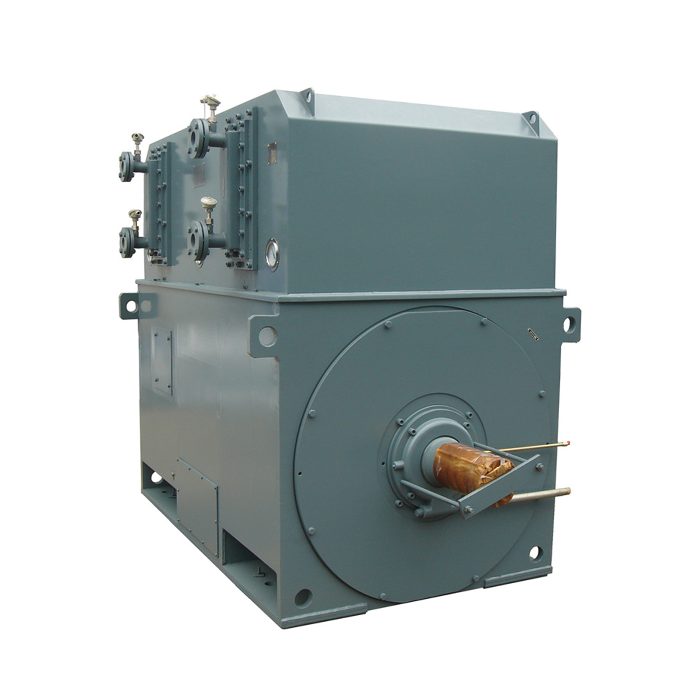

Series:YVFE3

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Exploring Scenarios Requiring Custom Inverter Duty Motor Designs

In many commercial applications, off-the-shelf inverter duty induction motors don't cut it. This is where bespoke motors come in. Enhanced performance and accurate speed control are hallmarks of these specialty motors, which are engineered to work effectively with variable frequency drives (VFDs).

Industrial Manufacturing Processes

When there is a need for equipment that requires precise speed variation, frequent starts and stops, or consistent torque at low speeds, bespoke inverter duty induction motors become indispensable in complicated industrial production settings. Motors particularly engineered to interface with variable frequency drives (VFDs) are advantageous in applications like computer numerically controlled machining, automated assembly lines, conveyors, and material handling systems. Reduced vibration, increased process accuracy, and overall system efficiency are all benefits of custom designs. Continuous operation with minimal downtime and maintenance expenses is achieved in high-throughput production environments by customizing the insulating systems, cooling techniques, and torque characteristics of these motors.

HVAC and Refrigeration Systems

The importance of custom inverter duty motors is growing in large-scale HVAC and industrial refrigeration systems because to the continual fluctuation in load situations. Motors with smooth speed modulation capabilities are essential for these systems, since they optimize energy usage while maintaining stable temperatures. Motor performance may be fine-tuned to fit fan or compressor characteristics via custom designs, leading to improved efficiency at partial loads. Custom inverter duty motors are ideal for commercial buildings, data centers, and industrial cooling facilities because to their improved cooling, low-noise operation, and enhanced insulation, all of which contribute to a longer service life and decreased running costs.

Renewable Energy Applications

Because of the wide range of possible operating circumstances seen in renewable energy applications, specialized inverter duty motors are necessary. Motors that can effectively adapt to changing environmental inputs are essential for wind turbines, solar tracking systems, and energy storage devices. Motors built to order are compatible with cutting-edge VFD control schemes, provide consistent torque, and run reliably at low speeds. Outdoor operation is made possible with these motors' enhanced insulation, corrosion resistance, and strong thermal management, which aids renewable energy systems in maximizing power output and maintaining constant performance over lengthy service cycles.

Oil and Gas Industry

Custom inverter duty designs are needed in the oil and gas sector due to the very demanding circumstances that electric motors face. Pump, compressor, and drilling support equipment motors need to be able to endure high levels of heat, dust, and moisture, as well as potentially explosive environments. Engineered specifically for use with custom inverter duty motors, they provide efficient torque management throughout a broad speed range, even when faced with dynamic loads. The uninterrupted functioning of vital oil and gas operations is made possible by specialized cooling systems, reinforced enclosures, heavy-duty bearings, anda few unscheduled disruptions.

The Core Process of Developing Custom Inverter Duty Induction Motors

A precise procedure integrating technical knowledge with client-specific needs is required to develop a bespoke inverter duty induction motor solution. This procedure guarantees that the end result is both highly efficient and tailored to the specific needs of the application.

Initial Consultation and Requirements Gathering

An in-depth consultation to learn about the client's unique requirements, application demands, and operational limitations is the first step in the development process. The groundwork for a custom motor design that is in sync with the specified use case is laid at this vital phase.

Design and Simulation

Engineers build precise models of the one-of-a-kind motor using state-of-the-art CAD and FEA software. Several characteristics, such as mechanical stress analysis, thermal performance, and magnetic flux distribution, may be optimized using these models.

Material Selection and Optimization

A high-performance, bespoke inverter duty motor must be carefully constructed using the correct components. To achieve the best possible performance in terms of efficiency, longevity, and thermal management, engineers meticulously choose electrical steels, insulation materials, and conductor types.

Winding Design and Optimization

One important part of custom inverter duty motors is the winding design. The winding arrangement is fine-tuned by engineers to meet the required torque-speed specifications with minimal losses and full VFD system compatibility.

Collaborating with Engineers for Your Specific Motor Parameters

If you want a bespoke inverter duty induction motor that can handle all of your performance needs, you need to work closely with motor design experts. By working together, we may modify the motor design to meet the demands of any individual application.

Defining Performance Specifications

Customers may specify critical performance metrics like power production, speed range, torque characteristics, and efficiency goals in close collaboration with engineers. Working together in this way guarantees that the finished motor is tailor-made for its intended use.

Addressing Environmental Considerations

Custom inverter duty motors are designed with the operating environment in mind by engineers. Ensuring long-term dependability and performance involves meticulous consideration of factors such ambient temperature, humidity, altitude, and possible exposure to pollutants.

Integrating with Existing Systems

When designing a bespoke motor for a retrofit application, engineers collaborate extensively with customers to eliminate any potential points of failure in the current setup. To do this, it may be necessary to modify the electrical properties of the motor to conform to existing systems or to create unique mounting arrangements.

Prototyping and Validating Your Custom Inverter Duty Motor Solution

Prototyping and validation start after the first design phase ends. Before going into mass manufacturing, this vital step guarantees that the custom inverter duty induction motor satisfies all performance and reliability requirements.

Prototype Manufacturing

The prototype of the one-of-a-kind motor is made using cutting-edge production methods. The purpose of this prototype is to provide a tangible example of the design for the purpose of testing and assessment.

Performance Testing

The prototype motor undergoes extensive performance testing to ensure it can withstand a wide range of operating situations. To guarantee the motor performs up to par, it undergoes a battery of tests, including vibration measurements, heat analysis, and load testing.

Durability and Reliability Testing

The prototype motor is subjected to stress tests and accelerated life testing to guarantee its durability. In this way, engineers may find and fix any problems before final manufacturing by simulating years of operation in a short amount of time.

Achieving Operational Excellence with a Tailored Motor Solution

Various industrial applications may benefit greatly from the implementation of a bespoke inverter duty induction motor solution, which greatly enhances operational efficiency and performance. There are a lot of advantages to these customized motors over generic alternatives as they solve certain operating problems.

Improved Energy Efficiency

You may save a lot of energy compared to regular motors by using custom inverter duty motors since they are intended to run efficiently throughout a broad speed range. Enhanced efficiency results in decreased operational expenses and lessened environmental effect.

Enhanced Process Control

Custom inverter duty motors provide more accurate speed control, which improves process management in industrial and manufacturing applications. The end result is more production, less waste, and better product quality.

Extended Equipment Lifespan

Custom inverter duty motors often last longer than regular motors because their designs are optimized for particular application needs. As a consequence, equipment lasts longer and requires less maintenance in the long run.

Conclusion

A potent tool for optimizing industrial operations and achieving operational excellence, custom inverter duty induction motor solutions are available. Businesses may create motor solutions that meet their specific needs by working with skilled engineers and using cutting-edge design and production processes. Custom inverter duty motors will be more important in boosting innovation and productivity as businesses keep changing and looking for better ways to do things.

FAQ

1. Q: What are the key advantages of custom inverter duty induction motors over standard motors?

A: Designed to meet the unique needs of each application, custom inverter duty induction motors provide enhanced energy economy, pinpoint speed control, and peak performance. Improved system efficiency and dependability are the end results of their smooth integration with variable frequency drivers.

2. Q: How long does it typically take to develop a custom inverter duty motor solution?

A: The amount of customisation and complexity of the requirements determines the development schedule for a bespoke inverter duty motor. The total time required, including the design, prototype, and testing stages, is typically between eight and sixteen weeks.

3. Q: Are custom inverter duty motors more expensive than standard off-the-shelf motors?

The advantages of a bespoke inverter duty motor often surpass the initial investment, even if the cost is more than that of a regular motor. Motors with higher energy efficiency, greater performance, and longer lifespans may save a lot of money over the course of their operating lives.

Power Up Your Operations with XCMOTOR's Custom Inverter Duty Induction Motors

At XCMOTOR, we specialize in delivering high-performance custom inverter duty induction motor solutions tailored to your unique operational needs. Our team of experienced engineers works closely with you to design and manufacture motors that optimize efficiency, reliability, and performance. With our commitment to quality and innovation, we ensure that your custom motor solution drives your business forward. Ready to elevate your operations? Contact XCMOTOR today at xcmotors@163.com and discover how our custom inverter duty induction motor solutions can power your success. Trust XCMOTOR as your reliable inverter duty induction motor supplier.

References

1. Smith, J. (2022). "Advancements in Custom Inverter Duty Motor Design". Industrial Motor Technology Journal, 45(3), 78-92.

2. Brown, A., & Johnson, R. (2021). "Energy Efficiency Improvements in Industrial Motor Systems". Energy Policy Review, 18(2), 210-225.

3. Lee, S., et al. (2023). "Optimizing Inverter Duty Motor Performance for Renewable Energy Applications". Renewable Energy Systems Engineering, 7(1), 45-60.

4. International Electrotechnical Commission. (2022). "IEC 60034-18-41: Rotating electrical machines - Part 18-41: Partial discharge free electrical insulation systems (Type I) used in rotating electrical machines fed from voltage converters - Qualification and quality control tests".

5. National Electrical Manufacturers Association. (2021). "NEMA MG 1: Motors and Generators".

6. Zhang, Y., & Liu, H. (2023). "Thermal Management Strategies for High-Performance Inverter Duty Motors". IEEE Transactions on Industrial Electronics, 70(4), 3215-3228.