Upgrading to inverter duty induction motors delivers transformative advantages for industrial operations. These specialized motors excel in variable frequency drive applications, offering superior durability under rapid acceleration, deceleration cycles, and varying load conditions. Unlike standard motors, they feature reinforced insulation systems that withstand voltage spikes, enhanced bearing protection against shaft currents, and optimized cooling designs. This upgrade typically results in 15-30% energy savings, reduced maintenance costs, and extended equipment lifespan, making it essential for modern manufacturing, HVAC systems, and process control applications.

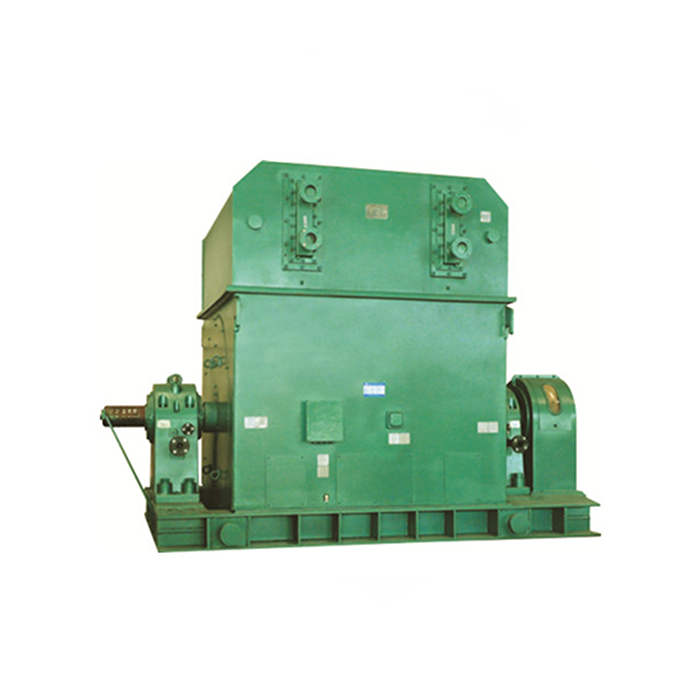

Series:YVFE3

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Key Performance Parameters That Drive Success

The specialized details of present-day inverter-compatible engines uncover why they outflank customary choices. Our engines work effectively over a recurrence ranges from 5Hz to 100Hz, pleasing assorted speed control necessities. The control run ranges 0.75kW to 1000kW, serving everything from little pumps to overwhelming mechanical compressors.

Motor effectiveness evaluations reach IE3 and IE4 measures, conveying control components surpassing 0.85 at full stack. The IP55 assurance level guarantees solid operation in challenging situations. These engines keep up steady torque characteristics from 5-60Hz, and then move to consistent control conveyance over 60Hz. This execution profile optimizes vitality utilization whereas assembly requesting operational requirements.

Voltage compatibility incorporates 380V, 400V, 415V, 660V, and 690V setups, pleasing worldwide control measures. The separator lesson F rating (155°C) gives warm security amid severe operations. Beginning current remains underneath 600% of the evaluated current, lessening the electrical push on control systems.

Core Benefits of Motor Modernization

Energy proficiency changes speak to the most compelling advantage of overhauling engine frameworks. Variable recurrence drive compatibility empowers exact speed control, disposing of energy waste from throttling valves or dampers. This control exactness decreases electrical utilization by 20-50% in ordinary applications. Operational adaptability increments essentially with movable speed drive innovation, permitting engines to coordinate correct handle prerequisites or maybe than running at settled speeds.

Enhancing Operational Performance

The upgrade enhances operational performance and process control. By enabling precise speed regulation and smooth acceleration profiles, advanced motor systems protect sensitive products and equipment while improving manufacturing quality. Specifically, the integration of an inverter duty induction motor, with its robust design for PWM inverter compatibility, eliminates the shock loads and vibration associated with conventional starting methods, ensuring superior accuracy and reliability in demanding applications.

Reducing Lifetime Costs

These improvements directly reduce lifetime costs through lower maintenance and energy expenses. Enhanced bearing protection, superior insulation systems, and vector control technology minimize torque ripple and mechanical stress, significantly extending component life. Furthermore, the reinforced construction of modern motors handles damaging harmonics and voltage spikes, leading to decreased downtime and repair costs alongside the substantial energy savings from optimized speed control.

Improving Workplace Environment

A significant additional benefit is the improvement of the workplace environment through noise reduction. Advanced motor cooling designs and reduced mechanical vibration create noticeably quieter operation compared to traditional systems. This reduction in noise pollution enhances overall working conditions for employees and assists facilities in meeting increasingly stringent industrial health, safety, and environmental noise compliance standards.

XCMOTOR's Superior Motor Solutions

Advanced Manufacturing and Components

Our inverter duty motors distinguish themselves through advanced manufacturing processes and premium components. We employ precision die-casting for rotor and stator cores, ensuring consistent magnetic properties and reduced losses. Automated winding machines deliver uniform coil quality, while vacuum pressure impregnation creates superior insulation integrity. This meticulous production is foundational to the reliability and performance of our Inverter Duty Induction Motor, establishing it for demanding industrial service.

Technical Specifications and Standards

Our bearing selection program includes SKF, NSK, and FAG options based on specific application requirements, ensuring optimal performance across diverse environments. Quality certification includes ISO 9001:2015 compliance and CE marking for European markets. Installation dimensions follow International Electrotechnical Commission standards, ensuring compatibility with existing equipment. This standardization simplifies retrofitting projects and reduces installation costs for the inverter duty induction motor.

Engineering Support and Delivery

Technical support capabilities exceed industry standards with dedicated weekend assistance. Our engineering team provides application-specific recommendations for optimal drive compatibility and performance, helping customers avoid common pitfalls. Delivery performance includes expedited options for urgent requirements, with standard lead times of 2-4 weeks and custom solutions within 4-6 weeks. This responsiveness effectively supports maintenance schedules and project timelines.

Maximizing Investment Returns Through Proper Implementation

Successful motor upgrades require careful system analysis and component matching. The carrier frequency settings must align with motor insulation capabilities to prevent premature failure. Our engineers recommend starting with conservative switching frequency settings, then optimizing based on application requirements.

Proper grounding techniques become critical with VFD installations. Electromagnetic interference can affect nearby sensitive equipment without adequate shielding. Installing appropriate line reactors and output filters protects both the motor and connected systems.

Motor protection settings require adjustment from conventional applications. Thermal overload protection must account for reduced cooling at low speeds. Current monitoring should reflect the motor's actual operating profile rather than nameplate values.

Cable selection impacts system performance significantly. Shielded VFD-rated cables minimize electromagnetic interference while maintaining signal integrity. Cable length limitations depend on motor size and drive capabilities, typically ranging from 150-300 feet without additional filtering.

Maintenance scheduling changes with inverter duty applications. Regular insulation testing becomes more important due to voltage stress from PWM waveforms. Bearing monitoring should include vibration analysis to detect early signs of electrical damage.

Critical Implementation Considerations

Environmental factors significantly influence motor selection and installation. High ambient temperatures require enhanced cooling provisions or motor derating. Dust, moisture, and corrosive atmospheres may necessitate higher IP ratings or special coatings.

Load characteristics must match motor capabilities throughout the operating range. Applications requiring high starting torque may need oversized motors or specialized designs. Continuous duty cycles demand different considerations than intermittent operations.

System harmonics increase with VFD installations, potentially affecting power quality. Input and output filtering may be required to meet utility standards and protect sensitive equipment. Power factor correction equipment might need adjustment or replacement.

Altitude and cooling considerations become critical in certain installations. Motor derating may be necessary above 3,300 feet elevation. Ambient temperature limits require verification against actual operating conditions rather than nameplate ratings.

Electrical compatibility extends beyond basic voltage matching. Inverter output characteristics must align with motor insulation capabilities. Some older VFD units may require motor compatibility verification before installation.

Conclusion

Upgrading to inverter duty induction motors represents a strategic investment that improves operational proficiency, unwavering quality, and generally competitiveness. These engines are particularly designed to work consistently with variable frequency drives, conveying significant energy savings through exact speed and torque control. Made strides in handling control leads to more steady generation, higher item quality, and decreased mechanical push on associated hardware. In expansion, optimized warm execution and strengthened separator frameworks altogether lower upkeep necessities and extend benefit life, diminishing add up to fetched of ownership. XCMOTOR's progressive engine arrangements, bolstered by comprehensive specialized help and strict quality benchmarks, guarantee smooth integration into existing frameworks and tried and true long-term operation. By receiving present-day inverter obligation engine innovation, offices can meet progressively rigid vitality effectiveness and natural controls whereas progressing operational adaptability. This move positions your operations for maintained execution, taken a toll control, and long-term victory in today's profoundly competitive mechanical marketplace.

Frequently Asked Questions

Q1: What makes inverter duty motors different from standard induction motors?

A: Inverter duty motors feature enhanced insulation systems designed to handle voltage spikes from PWM drives, improved bearing protection against shaft currents, and optimized cooling for variable speed operation. These design improvements prevent the premature failures common when standard motors operate with variable frequency drives.

Q2: How much energy savings can I expect from upgrading to VFD-compatible motors?

A: Energy savings typically range from 15-50% depending on the application. Pump and fan applications often see the highest savings due to the cubic relationship between speed and power consumption. Process applications with varying load requirements also achieve significant efficiency improvements.

Q3: Can existing VFD systems work with new inverter duty motors?

A: Most modern VFD systems are compatible with inverter duty motors, but parameter programming may require adjustment. Motor protection settings, acceleration/deceleration rates, and carrier frequency settings should be optimized for the specific motor characteristics. Our technical team provides application support for system integration.

Partner with XCMOTOR for Advanced Motor Solutions

XCMOTOR stands as your trusted inverter duty induction motor supplier, combining cutting-edge technology with proven reliability. Our comprehensive motor solutions serve diverse industries from manufacturing to renewable energy applications. With extensive experience in VFD compatibility and system integration, we deliver customized solutions that maximize operational efficiency and minimize total cost of ownership. Ready to transform your operations with superior motor technology? Contact us at xcmotors@163.com today.

References

1. IEEE Standards Association. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." IEEE Std 112-2017, Institute of Electrical and Electronics Engineers, 2018.

2. National Electrical Manufacturers Association. "Motors and Generators for Use with Power Electronics Converters and Variable Frequency Controls." NEMA Standards Publication MG 1-2016, Washington, D.C., 2016.

3. International Electrotechnical Commission. "Rotating Electrical Machines - Part 25: AC Motors for Use with Variable Frequency Converters." IEC 60034-25:2014, Geneva, Switzerland, 2014.

4. Bonnett, Austin H. and Christian Koegl. "Troubleshooting Motor Problems in VFD Applications." IEEE Industry Applications Magazine, vol. 20, no. 4, July-August 2014, pp. 12-21.

5. European Commission. "Commission Regulation on Ecodesign Requirements for Electric Motors." EU Regulation 2019/1781, Official Journal of the European Union, October 2019.

6. Motor and Drive Systems Professional Development Seminar. "Advanced Topics in Motor Design for Inverter Applications." Proceedings of the IEEE Industry Applications Society Annual Meeting, Portland, Oregon, 2018.