When selecting between a slip ring rotor motor and a squirrel cage motor for your industrial startup, the decision hinges on your specific operational requirements. Slip ring rotor motors excel in applications demanding high starting torque and variable speed control, making them perfect for heavy-duty apparatus like crushers and plants. In the meantime, squirrel cage engines offer straightforwardness and cost-effectiveness for standard applications. Understanding the principal contrasts between these wound rotor engines and conventional induction engines will direct your venture toward the most appropriate electromechanical energy transformation arrangement for your trade needs.

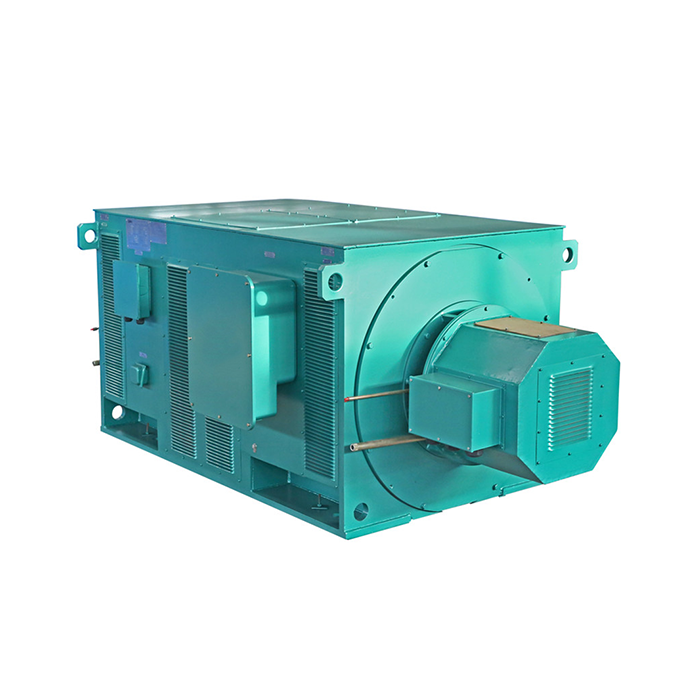

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-4500 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.2-2002 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Motor Construction Differences

The primary distinction between these two motor types lies in their rotor construction and slip ring assembly design. A slip ring rotor motor features external rotor windings connected through slip rings and brushes, enabling external resistance control. This configuration allows operators to modify the motor's startup characteristics and speed performance.

Conversely, squirrel cage rotors utilize aluminum or copper bars implanted inside the rotor center, shaping a cage-like structure. This plan disposes of the require for slip ring brushes and outside associations, making a less difficult but less adaptable system.

Key construction elements include:

- Rotor winding accessibility and control options

- Slip ring brush maintenance requirements

- Motor starting resistor integration capabilities

- Stator winding compatibility with control systems

If you need precise torque control during startup, slip ring rotor motors provide superior flexibility through their external resistance circuits.

Startup Performance Analysis

Starting execution speaks to a basic calculate when choosing between these engine types for mechanical applications. Real-world testing illustrates critical contrasts in startup current and torque characteristics, with particular preferences advertised by specialized designs.

Slip Ring Motor Starting Performance

The Slip Ring Rotor Motor achieves starting currents of approximately 350-450% of rated current while delivering up to 280% of rated torque. This superior combination results from the motor starting resistor's ability to optimize rotor resistance during the critical initialization phase, providing strong initial movement with less electrical strain.

Squirrel Cage Motor Starting Drawbacks

Standard squirrel cage engines regularly draw 500-800% of evaluated current during startup, whereas creating only 150-200% of appraised torque. These essentially higher current requests can strain the electrical foundation, possibly cause voltage plunges, and increase operational costs related to control quality and component sizing.

Comparative Performance Advantages

Performance data shows the Slip Ring Rotor Motor reduces electrical stress by 30-40% and delivers 40-80% higher initial torque than squirrel cage motors. This reduced starting current minimizes grid disturbances and voltage drop impact. For the needs to minimize infrastructure stress while maximizing startup torque, slip ring rotor motors offer measurable advantages.

Speed Control and Variable Operation Capabilities

Modern industrial processes increasingly require variable speed drive compatibility and precise motor torque control. These requirements significantly influence motor selection decisions for automation systems and process control applications, where the specific characteristics of a Slip Ring Rotor Motor are often highly advantageous.

Inherent Speed Control Capability

The Slip Ring Rotor Motor provides inherent speed variation through rotor resistance control, enabling smooth operation across different load conditions. This electromagnetic induction principle allows operators to adjust motor slip characteristics without additional electronic controls. This fundamental design offers a reliable mechanical method for managing speed, which serves as a robust foundation for system operation.

Enhanced Control with VFD Integration

Variable recurrence drives (VFDs) can upgrade both engine sorts, but slip ring engines offer double control strategies. Administrators can utilize either electronic speed control or conventional resistance-based alteration depending on application prerequisites. This adaptability permits for optimization based on particular needs for accuracy, taken a toll, or framework repetition, making the innovation versatile to complex mechanical environments.

Operational Advantages for Variable Speed

The speed control points of interest incorporate a double control technique and improved low-speed torque characteristics. Also, these engines contribute to decreased consonant mutilation in variable speed applications and moved forward vitality proficiency over working ranges. If you require adaptable speed control without total reliance on electronic drives, the wound rotor engine innovation gives both mechanical and electronic options.

Industrial Application Suitability

Different industrial sectors benefit from specific motor characteristics based on their operational demands. Understanding these applications helps determine the most appropriate rotating electrical machine for your business.

Slip ring rotor motors excel in:

- Cement and mineral processing equipment

- Large pumps and compressors requiring soft starting

- Conveyor systems handling variable loads

- Mining equipment operating under harsh conditions

Squirrel cage motors suit:

- HVAC fans and blowers with consistent loads

- Standard conveyor applications

- General-purpose industrial machinery

- Applications prioritizing maintenance simplicity

Manufacturing facilities in automotive, aerospace, and electronics industries often benefit from slip ring motors when handling heavy components or requiring precise speed control during production processes.

If you need reliable operation in demanding environments with variable load conditions, slip ring rotor motors provide superior adaptability and performance consistency.

Maintenance Requirements and Operational Considerations

Long-term operational costs significantly impact motor selection decisions. Understanding maintenance requirements and motor winding insulation demands helps calculate total ownership expenses.

Slip ring rotor motors require periodic slip ring brush replacement and rotor winding insulation monitoring. These maintenance tasks demand skilled technicians but occur at predictable intervals, typically every 12-18 months depending on operating conditions.

Squirrel cage motors offer reduced maintenance complexity due to their enclosed rotor design. However, bearing replacement and stator winding maintenance still require professional service at regular intervals.

Maintenance comparison factors:

- Component accessibility for routine service

- Specialized skill requirements for repairs

- Replacement parts availability and costs

- Downtime duration for scheduled maintenance

Modern slip ring assemblies incorporate improved materials and designs that extend service intervals while maintaining reliable performance. Quality manufacturers like XCMOTOR utilize premium components including SKF, NSK, and FAG bearings to enhance durability.

If you need predictable maintenance schedules with manageable complexity, both motor types offer viable solutions when properly maintained by qualified personnel.

Cost Analysis and Investment Considerations

Initial investment costs and long-term operational expenses vary significantly between these motor technologies. Comprehensive cost analysis includes equipment pricing, installation requirements, and operational efficiency factors.

Slip ring rotor motors typically require higher initial investment due to their complex construction and control systems. However, reduced starting current demands may eliminate expensive electrical infrastructure upgrades in existing facilities.

Energy efficiency considerations favor slip ring motors in variable load applications. Their ability to maintain high motor efficiency across different operating points reduces electrical consumption and associated costs.

Financial evaluation criteria:

- Equipment acquisition and installation costs

- Electrical infrastructure modification requirements

- Long-term energy consumption patterns

- Maintenance and replacement part expenses

Return on investment calculations should include productivity improvements from enhanced starting performance and reduced electrical disturbances in sensitive manufacturing environments.

If you need to balance initial investment with long-term operational benefits, slip ring rotor motors often provide superior value in demanding applications despite higher upfront costs.

XCMOTOR Slip Ring Rotor Motor Advantages

XCMOTOR's YRQ(JR) series represents advanced slip ring rotor motor technology designed for demanding industrial applications. Our motors deliver exceptional performance across diverse operational requirements.

Key advantages of XCMOTOR slip ring rotor motors:

- Robust Power Range: 45-800kW capacity handles everything from small process equipment to large industrial machinery

- Flexible Voltage Options: 380V±5% standard with 660V availability for specialized applications

- Superior Protection: IP23 rating ensures reliable operation in challenging industrial environments

- High Starting Torque: Up to 280% of rated torque enables smooth startup of heavy machinery

- Low Starting Current: 350-450% of rated current reduces electrical infrastructure stress

- Versatile Applications: Drives fans, compressors, pumps, crushers, ball mills, and transportation equipment

- Heavy-Duty Capability: Powers ships, cranes, wind turbines, and complex mechanical systems

- Quality Components: SKF, NSK, FAG bearings available per customer requirements

- Advanced Manufacturing: Precision winding and vacuum pressure impregnation ensure reliability

- Comprehensive Testing: Rigorous quality control at every production stage

- Extended Warranty: 12-month warranty from commissioning or 18 months from shipment

- Technical Support: Installation, commissioning, and training services worldwide

- Speed Range Flexibility: 500-1500 rpm operation with variable speed drive compatibility

- Excellent Heat Dissipation: IC01 cooling method maintains optimal operating temperatures

- High Overload Capacity: Handles demanding operational conditions reliably

These advantages position XCMOTOR slip ring rotor motors as premium solutions for industries requiring reliable, efficient, and versatile motor performance in challenging applications.

Conclusion

Choosing between slip ring rotor motors and squirrel cage alternatives requires careful evaluation of your specific operational requirements. Slip ring rotor motors excel in applications demanding high starting torque, variable speed control, and reduced electrical infrastructure stress. While initial investment may be higher, the operational benefits often justify the cost in demanding industrial environments. XCMOTOR's comprehensive YRQ(JR) series provides reliable solutions backed by quality components, rigorous testing, and global support services. Consider your startup requirements, operational demands, and long-term goals when making this critical equipment decision.

Partner with XCMOTOR for Premium Slip Ring Rotor Motor Solutions

Selecting the right slip ring rotor motor manufacturer determines your equipment's long-term performance and reliability. XCMOTOR combines advanced engineering with comprehensive support services to deliver superior industrial motor solutions. Our experienced team provides technical consultation, custom configurations, and worldwide installation support to ensure optimal system integration. With fast delivery, original parts from trusted brands, and dedicated weekend support, we eliminate common procurement challenges. Ready to explore how our slip ring rotor motor supplier capabilities can enhance your operations? Contact us at xcmotors@163.com for detailed specifications and pricing information.

References

1. Chapman, S.J. "Electric Machinery Fundamentals: Induction Motor Design and Applications." McGraw-Hill Engineering, 2019.

2. IEEE Standard 112-2017. "IEEE Standard Test Procedure for Polyphase Induction Motors and Generators." Institute of Electrical and Electronics Engineers, 2017.

3. Boldea, I. and Nasar, S.A. "The Induction Machines Design Handbook: Slip Ring and Squirrel Cage Motor Analysis." CRC Press, 2018.

4. National Electrical Manufacturers Association. "Motor Starting and Control Methods for Industrial Applications." NEMA Technical Publication, 2020.

5. Pyrhonen, J., Jokinen, T., and Hrabovcova, V. "Design of Rotating Electrical Machines: Industrial Motor Applications and Performance." John Wiley & Sons, 2021.

6. International Electrotechnical Commission. "IEC 60034-1: Rotating Electrical Machines - Part 1: Rating and Performance Standards." IEC Publications, 2022.