Choosing the right Inverter Duty Motor for 2026 automated systems requires careful consideration of variable frequency drive compatibility, thermal management, and efficiency standards. Modern industrial automation demands motors specifically engineered to handle PWM drive signals, harmonics reduction, and continuous speed regulation without compromising reliability. These specialized motors feature enhanced insulation systems, optimized cooling designs, and robust construction that ensures consistent performance across diverse industrial applications from manufacturing to energy utilities.

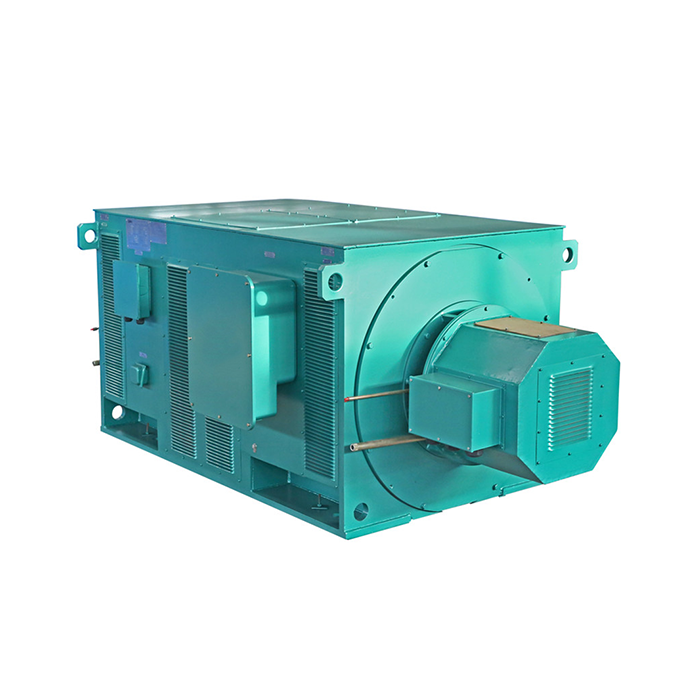

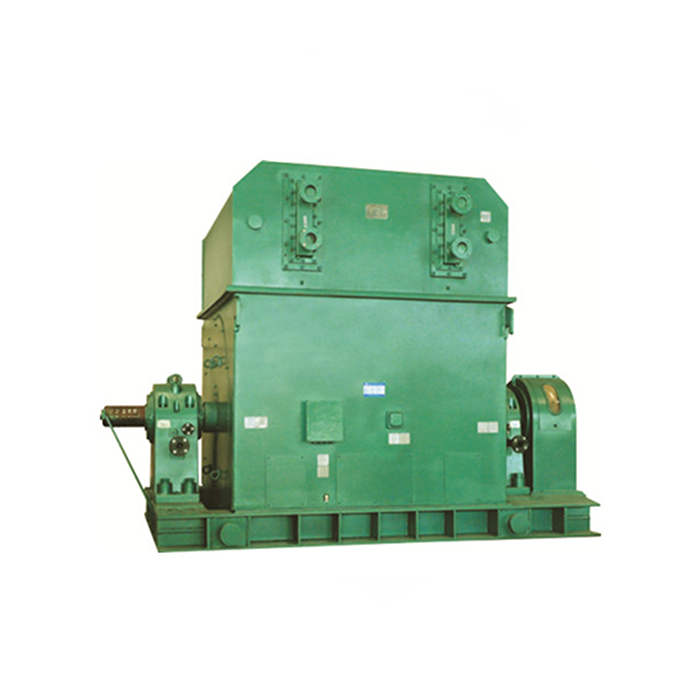

Series:YVFE3

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Advanced Motor Technology for Modern Automation

The scene of mechanical computerization proceeds rapidly as we approach 2026. Variable recurrence drives have ended up the spine of energy-efficient engine control frameworks, requiring specialized engines designed to handle complex working conditions. Not at all like standard engines, inverter-compatible units highlight fortified cover frameworks that withstand high-frequency exchanging and voltage spikes characteristic of PWM drives.

These engines join progressed warm administration advances fundamental for keeping up ideal execution amid persistent operation. Upgraded bearing security frameworks anticipate electrical discharge machining (EDM) harm caused by shaft streams, whereas optimized cooling plans guarantee reliable temperature control over shifting stack conditions.

Modern recurrence converters work inside extended ranges, ordinarily from 5Hz to 100Hz, requesting engines able of conveying full torque from zero speed to base frequency. This capability is pivotal for applications requiring exact speed direction and torque control, especially in mechanical technology and accurately fabricated equipment.

Critical Selection Criteria for Industrial Applications

Power requirements represent the fundamental starting point when selecting motors for automated systems. The available range spans from 0.75 kW to 355 kW, accommodating everything from small conveyor systems to large industrial compressors. Proper sizing ensures optimal energy efficiency while preventing premature equipment failure. An Inverter Duty Motor is specifically engineered to handle the variable speeds and torque demands of modern automated systems without compromising reliability. Its robust design addresses the unique electrical stresses from frequency drives, making it the optimal choice for applications requiring precise control and adjustable output, which is essential for energy savings and process optimization in complex automation.

Evaluating Voltage Compatibility

Voltage compatibility requires careful consideration, as frameworks may work at different levels counting 380V, 400V, 415V, 660V, and 690V arrangements. Multi-voltage choices like 220/380V and 400/690V give establishment adaptability over distinctive territorial control measures and application prerequisites. This flexibility is vital for worldwide sending of robotized hardware, guaranteeing engines can be coordinated consistently into existing electrical foundations without the requirement for exorbitant transformers or control conditioning units, subsequently lessening both initial setup complexity and long-term operational risks.

Assessing Protection and Insulation

Protection evaluations altogether affect engine life span, with IP55 advertising great dirt and dampness resistance for most mechanical situations. Cover course determination similarly influences unwavering quality; Lesson F separator appraised at 155°C gives prevalent warm assurance, while keeping up Course B temperature rise characteristics. Together, these details guarantee amplified benefit life and diminished upkeep beneath demanding conditions, such as in chemical preparation or marine applications, where natural components and nonstop operation pose noteworthy challenges to engine toughness and performance.

Industry-Specific Applications and Requirements

Manufacturing sectors, including automotive, aerospace, electronics, and food processing, require motors capable of handling frequent start-stop cycles and precise speed control. These applications often demand high overload capacity and excellent dynamic response characteristics for maintaining product quality and production efficiency, making an Inverter Duty Motor an optimal solution.

Demands of Process Control Applications

Process control applications utilize motors for pumps, valves, compressors, and other critical equipment where reliability directly impacts operational safety and efficiency. These systems require motors with superior harmonic tolerance and low vibration characteristics to ensure smooth operation and extended equipment life under continuous, controlled conditions.

Requirements for HVAC and Refrigeration

HVAC and refrigeration systems benefit from motors offering wide speed ranges and high efficiency ratings. Commercial installations particularly value energy savings potential, as these systems typically operate continuously and consume significant electrical power, making motor performance and efficiency critical for reducing long-term operational costs.

Robust Needs in Energy and Transportation

Energy, utility, and transportation applications demand robust construction and proven reliability. Motors in these sectors must maintain consistent performance across environmental extremes, withstand mechanical stress, and meet strict efficiency standards while prioritizing low maintenance and extended service intervals for dependable operation.

Efficiency Standards and Energy Optimization

Energy productivity speaks to a basic thought as businesses endeavor to diminish operational costs and natural affect. IE3 and IE4 proficiency appraisals have become standard desires, with premium proficiency engines conveying significant vitality reserve funds over their operational lifetime.

Adjustable speed drives combined with high-efficiency engines can accomplish vitality reserve funds of 20-50% compared to conventional fixed-speed frameworks. These reserve funds are especially critical in applications with variable stack requirements such as fans, pumps, and compressors.

Soft begin capabilities diminish mechanical stretch on driven gear, while minimizing electrical request amid startup. This include demonstrates particularly important for expansive engines where direct-on-line beginning seems to cause voltage unsettling influences or excessive mechanical shock.

Dynamic braking's usefulness empowers controlled deceleration and regenerative energy recovery in fitting applications. This capability upgrades both operational security and vitality productivity, especially in crane and lift applications where visit speed changes occur.

Technical Considerations and Performance Factors

Harmonic distortion management becomes increasingly important as more electronic equipment operates within industrial facilities. Motors designed for inverter duty incorporate features that minimize harmonic generation and improve power quality throughout the electrical system.

Bearing selection significantly impacts motor reliability and maintenance requirements. Premium bearing options from manufacturers like SKF, NSK, and FAG provide enhanced durability and extended service intervals, reducing total cost of ownership.

Cooling system design affects both performance and installation requirements. Totally enclosed fan-cooled (TEFC) designs offer excellent protection while maintaining efficient heat dissipation. Some applications may require external cooling or special ventilation arrangements.

Vibration and noise characteristics impact both equipment longevity and workplace environment quality. Motors designed for inverter duty typically incorporate balancing techniques and construction methods that minimize operational noise and vibration transmission.

Installation and Maintenance Best Practices

Proper installation practices ensure optimal motor performance and longevity. Accurate alignment, appropriate mounting techniques, and correct electrical connections prevent premature failure and maximize efficiency. IEC standard dimensions facilitate equipment replacement and system integration across different manufacturers, which is especially critical for specialized equipment like an Inverter Duty Motor.

Grounding and Electrical Safeguards

Grounding systems require special attention when installing motors with variable frequency drives. Proper grounding prevents shaft current circulation and reduces electromagnetic interference that could affect sensitive electronic equipment. This practice is non-negotiable for the reliable and safe operation of an Inverter Duty Motor, ensuring both motor integrity and system-wide compatibility.

Structured Preventive Maintenance

Preventive maintenance programs extend motor life and prevent unexpected failures. Regular inspections, lubrication schedules, and thermal monitoring help identify potential issues before they cause costly downtime. Adhering to a disciplined maintenance schedule is paramount for sustaining the performance and longevity of all critical drive components.

Environmental Protection Considerations

Environmental considerations including ambient temperature, humidity, and contamination levels affect motor selection and maintenance requirements. Proper environmental protection ensures reliable operation and minimizes maintenance costs over the motor's service life. Selecting the correct enclosure and implementing protective measures are essential steps for durable motor performance.

Future Trends and Technology Developments

Smart engine innovations are progressing with coordinate sensors and communication capabilities. These highlights empower prescient upkeep procedures and real-time execution checking that optimize framework effectiveness and anticipate unforeseen failures.

Magnetic bearing innovations offer potential for zero-maintenance arrangements in particular applications. Whereas as of now constrained to specialized employments, these innovations may become more broad as costs diminish and reliability improves.

Permanent magnet engine plans give predominant effectiveness and compact development compared to conventional internal combustion engines. In any case, taken a toll, contemplations, and attractive field administration prerequisites must be carefully assessed for each application.

Digital twin innovation empowers virtual engine testing and optimization, and, recently, physical testing. This approach decreases commissioning time and makes a difference optimize framework execution over changing working conditions.

Conclusion

Selecting fitting engines for 2026 mechanized frameworks requires a comprehensive understanding of application prerequisites, effectiveness benchmarks, and innovative capabilities. Cutting-edge inverter-compatible engines offer prevalent execution, vitality reserve funds, and unwavering quality compared to conventional options. Victory depends on cautious assessment of control necessities, natural conditions, and integration considerations. Working with experienced providers guarantees access to quality items, specialized mastery, and continuous support fundamental for fruitful computerization ventures. Speculation in premium engine innovation conveys long-term benefits through decreased energy costs, minimized maintenance needs, and improved framework unwavering quality over differing mechanical applications.

Ready to Upgrade Your Automated Systems with Premium Inverter Duty Motors?

XCMOTOR, as an Inverter Duty Motor supplier, delivers cutting-edge motor solutions engineered specifically for demanding industrial automation applications. Our comprehensive range of inverter duty motor options from trusted suppliers ensures optimal performance, energy efficiency, and reliability for your 2026 automation projects. Whether you need motors for manufacturing, HVAC, energy systems, or specialized applications, our technical team provides expert guidance and dedicated support. Contact us at xcmotors@163.com to discuss your specific requirements and discover how our advanced motor solutions can enhance your automation systems.

References

1. Institute of Electrical and Electronics Engineers. "IEEE Standard for Motor and Generator Design Guidelines for Variable Frequency Drive Applications." IEEE Standards Association, 2023.

2. International Electrotechnical Commission. "IEC 60034-17: Rotating Electrical Machines - Cage Induction Motors When Fed from Converters - Application Guide." IEC Publications, 2022.

3. National Electrical Manufacturers Association. "NEMA MG 1-2021: Motors and Generators - Performance Standards for Inverter Duty Applications." NEMA Standards Publication, 2021.

4. European Committee for Electrotechnical Standardization. "EN 50598-2: Ecodesign for Power Drive Systems and Equipment - Energy Efficiency Determination." CEN-CENELEC, 2023.

5. International Energy Agency. "Energy Efficiency in Electric Motor Systems: Technology Roadmap for Industrial Applications." IEA Technology Roadmaps, 2022.

6. American Society of Heating, Refrigerating and Air-Conditioning Engineers. "ASHRAE Guideline 36-2021: High-Performance Sequences of Operation for HVAC Systems with Variable Speed Drives." ASHRAE Publications, 2021.