Sourcing a reliable 4160 Volt Motor partner requires careful evaluation of manufacturing capabilities, technical expertise, and quality assurance measures. The most dependable providers give consistent item execution, worldwide certifications, total specialized support, and open communication throughout the buy process. These traits ensure your high-voltage engine speculation performs well and endures for fundamental mechanical applications. Worldwide mechanical engine request is rising as companies look for prudent, high-performance arrangements. Computerization and overwhelming businesses depend on 4160V engines. Worldwide clients may discover advanced innovation, reliable execution, and sensible cost in China, a major manufacturing center.

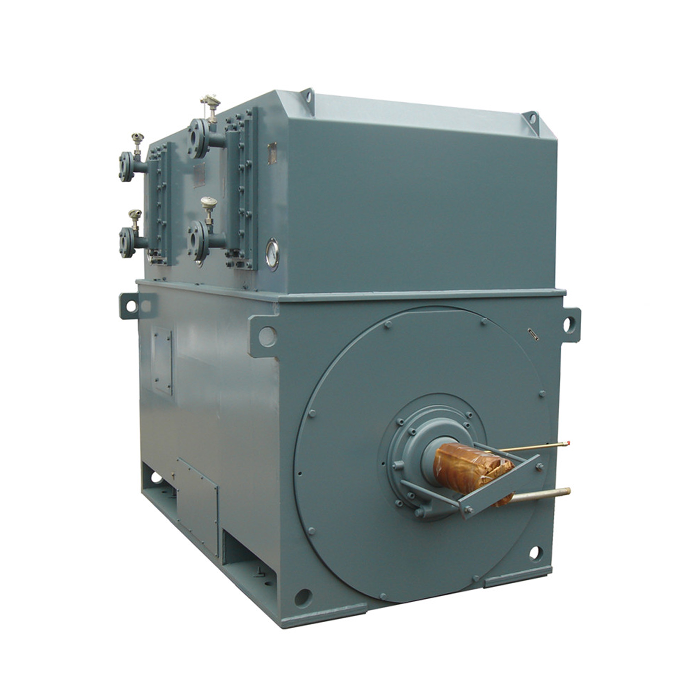

Series:YKS

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:220-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withGB/T 1032 and GB/T 13957 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

China's Competitive Edge in High-Voltage Motor Manufacturing

Advanced Production Capabilities

Chinese manufacturers use automated facilities, precision machining, and advanced materials to deliver consistent quality, high efficiency, and reduced costs. These capabilities support reliable production of demanding applications such as the 4160 Volt Motor.

Skilled Workforce and Technical Expertise

A exceedingly prepared workforce and solid R&D center empower Chinese providers to customize high-voltage engines, meet universal measures, and move forward proficiency, unwavering quality, and natural execution over assorted mechanical applications.

Essential Criteria for Evaluating Motor Manufacturers

Technical Specifications and Performance Standards

Reliable manufacturers provide clear specifications, verified testing reports, and compliance with IEC standards. Stable voltage tolerance, high efficiency ratings, and suitability for applications such as a 4160 Volt Motor are essential indicators.

Manufacturing Quality Control Systems

Established providers actualize strict quality control from materials to last testing. Comprehensive reviews, warm and vibration tests, and full traceability frameworks diminish disappointment dangers and guarantee reliable engine reliability.

Customization and Engineering Support

Leading producers offer adaptable plans, custom voltages, mounting alternatives, and cooling arrangements. Solid designing bolster guarantees engines are optimized for particular loads, situations, and long-term operational performance.

Supply Chain Management and Delivery Performance

Reliable providers keep up steady supply chains and proficient coordination. Steady fabric accessibility, exact conveyance plans, and defensive bundling guarantee both standard and customized engines arrive on time and intact.

After-Sales Support and Service Network

Strong after-sales support incorporates specialized help, parts access, and training programs. Worldwide benefit systems and clear documentation offer assistance to clients keep up engine productivity and extend operational lifespan.

Critical Certification Standards and Compliance Requirements

International Quality Management Systems

ISO 9001:2015 guarantees reliable quality control, documentation, and persistent advancement, whereas ISO 14001 reflects capable natural administration and compliance over manufacturing operations.

Product Safety and Performance Certifications

IEC 60034, CE, and UL certifications verify safety, insulation, and performance standards, reducing approval barriers and ensuring reliable operation for demanding applications such as the 4160 Volt Motor.

Environmental Compliance Standards

RoHS and REACH compliance limit hazardous substances and ensure chemical safety, while energy efficiency certifications highlight motors that reduce operating costs and support regulatory incentives.

Effective Procurement Channels and Platform Selection

Direct Manufacturer Relationships

Establishing coordinate connections with engine producers frequently gives the best combination of estimating, specialized support, and customization alternatives. Coordinate organizations dispense with middle-person markups, while guaranteeing clear communication channels for specialized requirements and conveyance expectations.

Manufacturer connections empower a much better understanding of generation capabilities, quality frameworks, and designing assets. This information makes a difference, buyers make educated choices and create long-term supply methodologies that adjust with operational requirements.

Specialized B2B Platforms

Professional B2B stages interface buyers with confirmed engine producers, while giving extra due diligence and exchange security. These stages regularly incorporate provider confirmation services, quality evaluations, and secure installment frameworks that diminish acquisition risks.

Advanced look capabilities on specialized stages offer assistance in recognizing providers with particular specialized capabilities, certifications, and geographic scope. Client audits and appraisals give insight into provider execution and client fulfillment levels.

Industry Trade Shows and Exhibitions

International exchange shows give opportunities to assess numerous providers at the same time, while watching item exhibits and specialized introductions. These occasions encourage face-to-face talks with design groups and choice creators who can address complex specialized requirements.

Trade appears regularly highlight modern item presentations and innovation shows that exhibit producer capabilities and development levels. Organizing openings at these occasions can lead to key associations and favored provider relationships.

Strategic Approaches to OEM and ODM Partnerships

OEM Collaboration Benefits

Original Equipment Manufacturer partnerships enable private labeling of motors while leveraging established production capabilities and quality systems. OEM arrangements typically offer competitive pricing for volume purchases while maintaining brand identity and customer relationships.

Technical collaboration in OEM partnerships can lead to product improvements and application-specific optimizations. Manufacturers often share engineering resources and testing facilities to develop enhanced solutions that benefit both parties.

ODM Development Opportunities

Original Design Manufacturer partnerships provide access to advanced engineering capabilities for developing custom motor solutions. ODM relationships work particularly well for specialized applications requiring unique performance characteristics or environmental specifications.

Design collaboration allows buyers to influence product development while benefiting from manufacturer expertise in motor design and production optimization. These partnerships often result in innovative solutions that provide competitive advantages in specific market segments.

Smart Negotiation Strategies for MOQ and Pricing

Minimum Order Quantity Optimization

Understanding manufacturer production economics helps negotiate reasonable minimum order quantities that balance inventory costs with unit pricing advantages. Many suppliers offer flexibility in MOQ requirements for established customers or long-term supply agreements.

Consolidating orders across multiple motor types or specifications can help achieve volume discounts while meeting minimum order requirements. Strategic timing of orders to align with manufacturer production schedules may also provide MOQ flexibility and improved pricing.

Value-Based Pricing Negotiations

Focus negotiations on total cost of ownership rather than initial purchase price alone. Consider factors such as energy efficiency, maintenance requirements, warranty coverage, and expected service life when evaluating pricing proposals.

Long-term supply agreements often provide better pricing stability and preferential treatment during periods of high demand or material cost fluctuations. These arrangements benefit both buyers and suppliers through predictable order volumes and revenue streams.

Comprehensive Factory Assessment and Quality Validation

Production Facility Evaluation

Comprehensive factory audits should evaluate production equipment, quality control systems, and workforce capabilities. Modern manufacturing facilities demonstrate investment in technology and commitment to quality through advanced machining centers, automated assembly systems, and environmental control measures.

Material handling systems and inventory management procedures indicate operational efficiency and quality control capabilities. Clean, organized production environments typically correlate with better product quality and more reliable delivery performance.

Quality System Documentation Review

Examine quality manuals, work instructions, and testing procedures to understand how manufacturers ensure consistent product quality. Comprehensive documentation systems indicate systematic approaches to quality control and continuous improvement.

Review supplier qualification procedures, incoming inspection protocols, and non-conformance handling processes. These systems directly impact final product quality and delivery reliability.

Testing Capability Assessment

Evaluate testing equipment and procedures used for motor validation and quality assurance. Comprehensive testing capabilities should include electrical performance testing, mechanical analysis, and environmental validation under various operating conditions.

Calibration records and testing documentation demonstrate commitment to accurate measurements and reliable test results. Advanced testing capabilities often indicate higher quality products and better technical support.

Leading Supplier Characteristics for 2025 Market Conditions

Digital Transformation and Industry 4.0 Integration

Leading manufacturers adopt IoT, predictive maintenance, and remote monitoring to improve reliability and reduce downtime. These digital capabilities enhance lifecycle management and performance optimization for complex equipment such as the 4160 Volt Motor.

Sustainability and Environmental Responsibility

Top suppliers emphasize energy-efficient manufacturing, recyclable materials, and low-carbon processes. Improved motor designs increase efficiency, extend service life, and help customers meet sustainability goals while lowering long-term operational costs.

Supply Chain Resilience and Risk Management

Resilient suppliers maintain diversified sourcing, flexible production, and strong inventory strategies. Effective risk management ensures stable quality, reliable delivery, and financial security despite market volatility or global supply disruptions.

Conclusion

Selection of the proper 4160 Volt Motor manufacturer demands rigorous examination of specialized abilities, quality frameworks, and commerce hones. Fruitful associations incorporate competitive cost, tried and true execution, comprehensive support, and vital alignment with long-term operational targets. Progressed generation, master designing, and competitive structures make Chinese fabrication attractive.

Buyers ought to select providers that offer steady quality, pertinent certifications, and total specialized bolster all through the item lifetime. Appropriate provider appraisal and relationship advancement increment item steadfastness, TCO, and operational efficiency.

Frequently Asked Questions

Q1: What voltage tolerances should I expect from quality 4160V motors?

A: Quality producers ordinarily keep up voltage resiliences inside ±5% of evaluated values. This implies a 4160V engine ought to work viably inside a range of 3952V to 4368V. Legitimate providers give point by point determination sheets affirming these resistance ranges and testing methods utilized for verification.

Q2: How do I verify the quality credentials of a Chinese motor manufacturer?

A: Confirm ISO 9001:2015 certification, IEC 60034 compliance, and important security certifications like CE or UL acknowledgment. Ask for production line review reports, quality control documentation, and client references. Numerous providers, moreover,r give third-party review administrations and quality confirmation through recognized testing laboratories.

Q3: What protection rating should I specify for industrial motor applications?

A: IP54 security gives satisfactory security for most indoor mechanical applications, whereas IP55 offers upgraded security for more demanding situations. Consider components such as tidy introduction, dampness levels, and cleaning prerequisites when selecting fitting assurance appraisals for your particular application.

Q4: What is the typical lead time for custom high-voltage motor orders?

A: Standard engine setups regularly require 4-8 weeks for generation and conveyance, whereas custom plans may require 8-16 weeks, depending on complexity. Producers with proficient production frameworks and great supply chain management regularly offer more unsurprising conveyance plans and superior communication with respect to arrange status.

Partner with XCMOTOR for Reliable High-Voltage Motor Solutions

XCMOTOR stands out as a trusted 4160 Volt Motor supplier with proven expertise in high-voltage motor manufacturing and comprehensive customer support. Our commitment to quality, competitive pricing, and technical excellence makes us the ideal partner for your industrial motor requirements. Experience our fast delivery service, 30-day return policy, and dedicated weekend support that sets us apart from conventional suppliers. Ready to explore premium motor solutions for your applications? Contact us at xcmotors@163.com to discuss your specific requirements with our technical team.

References

1. International Electrotechnical Commission. "IEC 60034 Series - Rotating Electrical Machines Standards." Geneva: IEC Publications, 2022.

2. Zhang, Wei and Liu, Ming. "Industrial Motor Manufacturing in China: Quality Systems and Global Competitiveness." Journal of Industrial Engineering, Vol. 45, No. 3, 2023, pp. 78-92.

3. Thompson, Robert K. "High-Voltage Motor Selection and Procurement Best Practices." Industrial Electrical Systems Quarterly, Vol. 28, No. 2, 2023, pp. 156-171.

4. European Commission. "Energy Efficiency Standards for Industrial Motors: Implementation Guide." Brussels: EU Publications Office, 2023.

5. Anderson, Sarah J. and Chen, David L. "Supply Chain Management in Global Motor Manufacturing." International Business Review, Vol. 67, No. 4, 2023, pp. 234-251.

6. National Institute of Standards and Technology. "Motor Testing and Certification Requirements for Industrial Applications." NIST Special Publication 800-147, 2023.