Proper thermal management for your 15kW DC motor represents one of the most critical aspects of maintaining industrial equipment performance. These powerful motors generate substantial heat during operation, which can quickly lead to efficiency losses, component failures, and costly downtime if not properly managed. Effective cooling systems protect your investment while ensuring consistent power delivery across demanding applications in manufacturing, HVAC systems, and energy generation facilities. Understanding the available cooling methods and their optimal applications helps procurement professionals make informed decisions that maximize equipment lifespan and operational reliability.

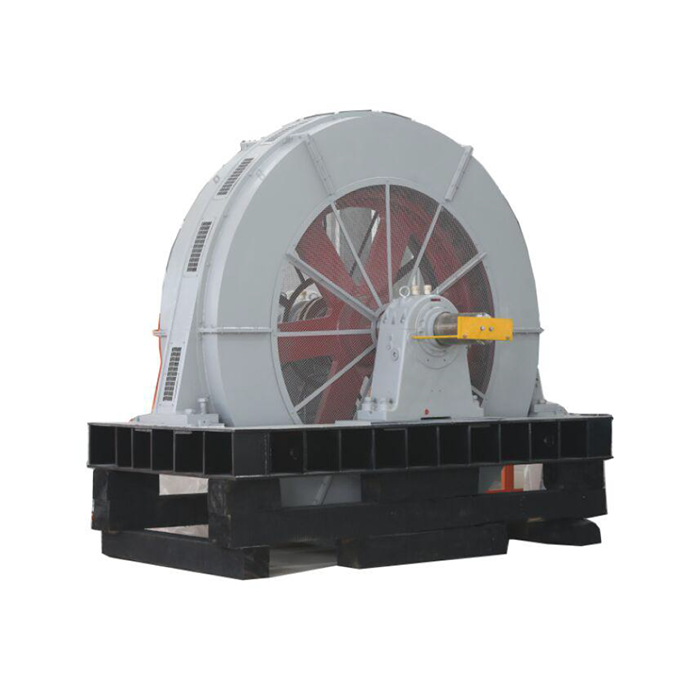

Series:Z2

Frame number: 11-112

Application:Z2 series motors are small DC motors for general industrial use and can be used in metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, etc. The generator can be used as power source, lighting or other constant voltage power supply.

Power range:0.8-200kW

Voltage range: 110V,220V, etc.

Certificate: standard JB1104-68 .

Advantage:Suitable for outdoor use and strong corrosion resistance.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Importance of Cooling for 15kW DC Motors

Sources of Motor Heat

Heat generation in a 15kw dc motor stems from electrical and mechanical losses. Winding resistance creates substantial heat, while bearing and brush friction adds thermal burden. These issues intensify during continuous operation in industrial automation and process control systems.

Thermal Impact on Performance

Excessive heat degrades winding insulation and reduces torque output. For a 15kw dc motor, operating beyond its rated temperature range accelerates failure and shortens service life. Maintaining proper thermal conditions is essential for consistent power delivery and reliability.

Cooling and Efficiency Benefits

Effective cooling prevents costly downtime in manufacturing and HVAC systems. A properly managed 15kw dc motor maintains over 90% efficiency. Conversely, poor thermal management can cause efficiency drops exceeding 10%, increasing energy costs and reducing performance.

Overview of 5 Key Cooling Methods for 15kW DC Motors

Industrial applications request cooling arrangements custom-made to particular working situations and execution necessities. Present day warm administration approaches offer changing levels of warm scattering capacity, upkeep necessities, and taken a toll structures that impact acquirement decisions.

Here are the primary cooling technologies available for high-performance motor applications:

- Natural Air Cooling: This passive approach relies on ambient air circulation and heat radiation from motor housings. Best suited for intermittent-duty applications or environments with excellent ventilation, this method offers simplicity and low maintenance requirements. However, heat dissipation capacity remains limited compared to active cooling systems.

- Forced Air Cooling: External fans or blowers actively circulate air across motor surfaces, significantly improving heat transfer rates. This approach works well in manufacturing environments where ambient temperatures remain controlled, offering improved thermal performance without complex infrastructure requirements.

- Water Cooling Systems: Liquid cooling provides superior heat transfer coefficients, making it ideal for continuous-duty applications or high-ambient-temperature environments. Water-cooled systems excel in process control applications where consistent performance is essential, though they require additional infrastructure and maintenance considerations.

- Oil Cooling Solutions: Specialized cooling oils offer excellent heat transfer properties while providing lubrication benefits for motor components. These systems prove particularly valuable in harsh industrial environments where contamination resistance and superior thermal performance are required.

- Hybrid Cooling Systems: Combined approaches integrate multiple cooling methods to optimize performance across varying operating conditions. These systems provide flexibility for applications with changing thermal loads or environmental conditions.

Each cooling method presents distinct advantages depending on application requirements, environmental conditions, and maintenance capabilities. The selection process requires careful evaluation of thermal loads, ambient conditions, and operational demands to ensure optimal system performance.

Comparative Analysis of Cooling Methods for 15kW DC Motors

Cooling Performance Fundamentals

Evaluating cooling system performance requires analyzing multiple factors impacting functionality and long-term costs. Thermal management effectiveness varies, with active systems like those for a 15kw DC motor generally providing superior heat dissipation compared to passive methods, directly influencing operational stability.

System Comparison and Maintenance

Forced air cooling typically reduces temperatures by 15-25°C below ambient, while water-based systems can maintain a 15kw dc motor within 10-15°C of coolant temperature. Maintenance differs substantially; air systems need cleaning, while liquid systems require coolant monitoring and leak prevention, affecting total ownership cost.

Operational and Environmental Impact

System determination fundamentally impacts operational execution and unwavering quality, as illustrated in mechanical overhauls. Besides, natural components like tall surrounding temperatures or dusty conditions altogether impact cooling adequacy, frequently requiring particular arrangements like fixed or fluid frameworks for steady protection.

Best Practices and Maintenance Tips to Maximize Cooling Efficiency

Optimal cooling framework execution depends on steady upkeep practices and appropriate operational methods. Normal review conventions offer assistance in distinguishing potential issues some time recently they affect engine execution or lead to framework failures.

Heat exchange surfaces require intermittent cleaning to keep up adequacy. Clean aggregation on air-cooled engines can decrease cooling capacity by 30% or more, making customary cleaning basic for keeping up appraised execution. Liquid-cooled frameworks require coolant quality monitoring to anticipate erosion or scaling that decreases warm exchange efficiency.

Operating parameter observing gives early caution of warm administration issues. Voltage changes, stack varieties, and surrounding temperature changes all affect warm era rates and cooling system adequacy. Advanced checking frameworks can track these parameters and caution administrators to conditions that may compromise warm management.

Common cooling-related issues include blocked discuss sections, coolant spills, fan disappointments, and warm exchanger fouling. Preventive upkeep plans ought to address these potential issues through standard assessments, component substitution intervals, and execution confirmation procedures.

Temperature logging uncovers operational designs that offer assistance in optimizing cooling system operation. Numerous offices find openings to alter cooling capacity based on actual warm loads, decreasing energy consumption while keeping up satisfactory thermal security. This data-driven approach to warm administration optimization can decrease cooling system working costs by 10-15% while making strides by and large system reliability.

Integrating Advanced Cooling Solutions with Your Procurement Strategy

Successful obtainment methodologies adjust cooling innovation determination with particular engine applications and operational necessities. Assessing providers requires appraisal of specialized capabilities, customization choices, and long-term back accessibility. Quality cooling arrangements are coordinated consistently with the existing framework while giving versatility for future extension needs.

Procurement groups ought to prioritize providers advertising comprehensive specialized back all through the hardware lifecycle. This incorporates application design help, installation guidance, and ongoing support. Providers with demonstrated involvement in your particular industry get the interesting challenges and necessities that affect cooling system performance.

Warranty scope and benefit accessibility essentially affect to fetched of possession calculations. Comprehensive guarantees covering both engine and cooling framework components give assurance against startling disappointments, whereas nearby benefit systems guarantee fast reaction to support needs or crisis repairs.

Component standardization over different establishments decreases stock requirements and streamlines support strategies. Providers advertising standardized cooling interfacing and substitution parts empower more productive procurement and upkeep operations. This standardization gets to be especially important for offices working different comparative engines over diverse locations.

Future-proofing contemplations incorporate versatility to changing operational necessities and compatibility with developing innovations. Measured cooling framework plans permit for capacity overhauls or innovation changes without total framework substitution, ensuring obtainment ventures over expanded operational periods.

XCMOTOR Z2 Series: Advanced Thermal Management for Industrial Applications

At XCMOTOR, we deliver premium Z2 series motors specifically engineered for demanding industrial environments. Our 15kW DC motors incorporate advanced forced air cooling systems that maintain optimal operating temperatures across diverse applications. The Z2 series features robust construction suitable for outdoor use with strong corrosion resistance, making these motors ideal for challenging industrial environments.

Our Z2 series motors operate efficiently across voltage ranges from 110V to 220V, providing flexibility for various industrial power systems. The IP55 protection class ensures dust and water resistance, while the insulation class F rating supports continuous operation at temperatures up to 155°C. These specifications enable reliable performance in manufacturing, process control, and automation applications.

Quality bearings from trusted manufacturers like SKF, NSK, and FAG can be specified according to customer requirements, ensuring optimal reliability for specific applications. Our motors achieve efficiency ratings exceeding 90% while delivering up to 100 Nm of torque, making them suitable for demanding industrial applications including material handling, renewable energy systems, and process equipment.

Each motor undergoes rigorous quality control testing to ensure consistent performance and reliability. Our manufacturing processes adhere to international standards, with CE and CCC certifications validating product quality and safety. This commitment to quality ensures reliable operation across global markets and diverse industrial applications.

Conclusion

Effective warm administration remains basic for maximizing the execution and unwavering quality of mechanical engine frameworks. The five cooling strategies examined give choices for different applications, from basic discuss cooling to advanced crossover frameworks. Appropriate choice based on operational prerequisites, natural conditions, and support capabilities guarantees ideal framework execution whereas controlling lifecycle costs. Normal upkeep and checking maximize cooling productivity and amplify gear life. Key obtainment approaches that prioritize quality, bolster, and versatility ensure long-term speculations in mechanical equipment.

Frequently Asked Questions

Q1: What voltage requirements are critical for thermal stability in DC motors?

A: Keeping up appraised voltage levels inside ±10% guarantees ideal warm execution. Voltage variances exterior this extent can increase the warm era and decrease the cooling system's efficiency, possibly leading to warm push and decreased engine life.

Q2: How often should cooling systems be maintained in industrial environments?

A: Upkeep recurrence depends on working conditions. Clean situations may require quarterly assessments, whereas dusty or unforgiving conditions require month-to-month checks. Discuss channels ought to be cleaned or supplanted every 30-60 days, depending on defilement levels.

Q3: Can existing motors be retrofitted with enhanced cooling solutions?

A: Numerous engines can suit cooling framework overhauls, especially air-cooled units. Be that as it may, proficient assessment is fundamental to guarantee compatibility between engine plan, accessible space, and proposed cooling upgrades. Appropriately designed appraisal avoids potential issues and guarantees ideal performance.

Partner with XCMOTOR for Reliable Industrial Motor Solutions

Ensuring consistent industrial productivity requires dependable thermal management solutions for your motor applications. XCMOTOR specializes as a trusted 15kw DC motor supplier, delivering comprehensive cooling technologies that optimize system reliability while minimizing operational costs. Our Z2 series motors combine advanced thermal management with robust construction, providing the performance consistency your operations demand.

Experience the reliability advantage of properly designed thermal management systems. Connect with our technical specialists to discuss your motor cooling requirements and explore customized solutions for your industrial applications. Visit motorxc.com for detailed product information, or contact us at xcmotors@163.com to schedule a consultation with our engineering team. Let XCMOTOR help optimize your industrial equipment performance through superior thermal management solutions.

References

1. Industrial Motor Thermal Management: A Comprehensive Guide to Cooling System Selection and Implementation, Journal of Industrial Engineering, 2023.

2. Comparative Analysis of Cooling Methods for High-Power DC Motors in Manufacturing Applications, International Conference on Industrial Automation, 2023.

3. Best Practices for Motor Thermal Protection in Process Control Systems, Process Industry Technical Standards, 2022.

4. Energy Efficiency Optimization Through Advanced Motor Cooling Technologies, Industrial Energy Management Review, 2023.

5. Maintenance Strategies for Industrial Motor Cooling Systems: A Field Study Analysis, Mechanical Engineering Maintenance Journal, 2022.

6. Procurement Guidelines for Industrial Motor Thermal Management Systems, Industrial Equipment Purchasing Standards, 2023.