Why YBX5 Explosion-Proof Motors Are Ideal for Oil Refineries?

Safe and effective operations in oil refineries are made possible only with specialist equipment due to the complexity and hazards of the environment. Powering a wide range of equipment and procedures, explosion-proof motors are an essential part of these facilities. By analyzing their design, safety characteristics, and long-term advantages, this article will explain why YBX5 explosion-proof motors are especially suitable for use in petroleum refineries.

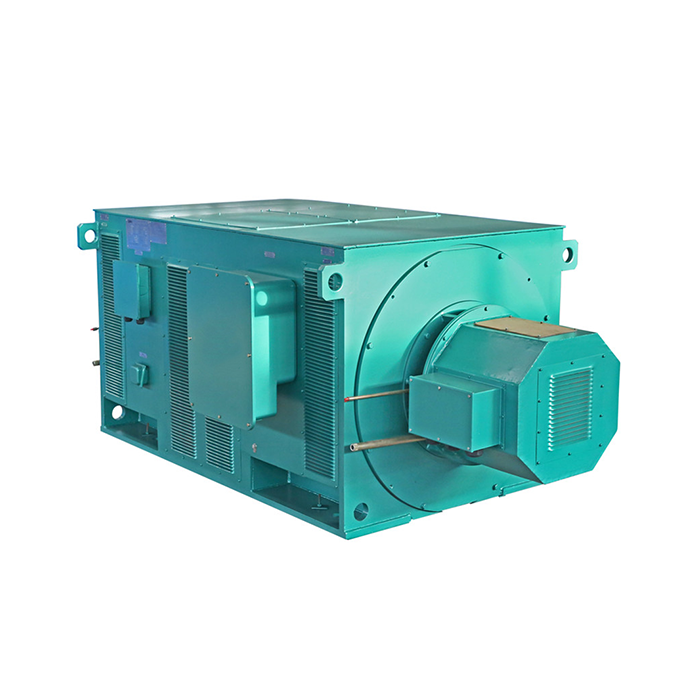

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What are the Specific Hazards in Oil Refineries That Demand Explosion-Proof Motors?

Specialized machinery, such as motors that are resistant to explosions, is required in oil refineries due to the specific hazards and problems that these facilities provide. If you want to know why YBX5 explosion-proof motors are so important in these settings, you have to know about these dangers.

Flammable Vapors and Gases

The primary hazard in oil refineries is the presence of flammable vapors and gases. These substances are byproducts of the refining process and can easily ignite if exposed to an electrical spark or excessive heat. Common flammable gases in refineries include:

- Hydrogen sulfide

- Methane

- Propane

- Butane

These gases can form explosive mixtures with air, creating a potentially catastrophic situation if ignited.

Combustible Dust

Combustible dust is another major threat in oil refineries. This airborne fine particulate matter may be produced by a variety of refining procedures. These dust particles, when airborne, may condense into explosive clouds that only a little spark or heat source needs to set ablaze.

High Temperatures and Pressures

Additional risks might arise from the high heat and pressures used in oil refining procedures. Equipment failure, leaks, or ruptures caused by these circumstances might release combustible elements into the environment.

Corrosive Substances

Oil refineries consume and create a lot of chemicals, and some of those compounds are quite corrosive. Equipment may be worn down by these chemicals over time, which might cause breakdowns that discharge volatile compounds or create ignition sources.

Electrical Equipment as Potential Ignition Sources

In dangerous settings, sparks, overheating, or arcing from conventional motors may ignite dust or gases that are combustible. In order to guarantee safe operation and dependable continuity in oil refinery applications, YBX5 explosion-proof motors are designed to reduce these hazards.

Key Design Features of YBX5 Motors for Combustible Gas and Dust Environments

Oil refineries and other places with flammable gases and dust are perfect places to employ YBX5 explosion-proof motors because of their many useful design characteristics. All of these safety measures ensure that the engine won't catch fire, no matter how close it gets to combustible materials.

Robust Enclosure Design

The sturdy housing design is a key component of YBX5 motors. In the event of an internal explosion, the motor's casing is made of a high-strength material (usually steel or cast iron) that prevents the escape of flames or hot gasses. Any potential internal ignition cannot escape into the potentially dangerous atmosphere due to this confinement.

Flame Paths

YBX5 motors incorporate carefully engineered flame paths in their design. In the case of an internal explosion, these snugly fitting seams between sections of the motor housing would relieve pressure while blocking the flow of flames. To make sure these flame routes work, their dimensions and tolerances are computed with great precision.

Temperature Control

In order to keep combustible gases and dust from igniting around a YBX5 motor, its exterior is engineered with efficient heat dissipation systems. To maintain surface temperatures below the ignition point of potentially dangerous compounds, thermal management systems may be used, which may include cooling fins, internal fans, or other means.

Sealed Cable Entries

In order to keep dust and combustible gases out of the motor, every cable entry has been meticulously sealed. To do this, certified explosion-proof cable glands are usually used, which keep the motor's explosion-proof housing intact.

Anti-Static Features

The YBX5 motors are equipped with anti-static characteristics that prevent the accumulation of static charge, which might lead to sparks. Methods for securely dissipating static electricity may include the use of conductive materials and grounding points.

Corrosion-Resistant Materials

Materials that resist corrosion are used to create YBX5 motors, considering the typically corrosive environment found in oil refineries. This does double duty: it keeps the engine in good working order for a longer period of time and guards against deterioration that may render it less explosion-proof.

Certified Components

Bearings, seals, and electrical components of YBX5 motors have all been approved for use in explosive environments, guaranteeing that they meet all necessary safety requirements. Reducing electrical dangers and ensuring continuous, secure operation in hazardous situations, YBX5 explosion-proof motors are a dependable and safe option for oil refinery operations thanks to their integrated design characteristics.

How the Construction of YBX5 Motors Prevents Ignition of Flammable Substances?

For use in dangerous settings, such as oil refineries, YBX5 explosion-proof motors are designed to prevent combustible materials from setting fire to themselves. A safe and dependable motor is the result of a conglomeration of design elements and production processes that accomplish this.

Explosion-Proof Enclosure

An explosion-proof housing is the YBX5 motor's principal line of defense against ignition. If an explosion were to happen inside, this cage would confine it so it wouldn't set the surrounding environment on fire. In order to endure enormous interior pressures, the enclosure is usually constructed from thick, high-strength materials like steel or cast iron.

Precision-Engineered Flame Paths

YBX5 motors have flame routes that are meticulously planned at every junction and aperture in the motor housing. Long, thin holes called flame channels let pressure out in the case of an internal explosion but keep flames and hot gases out. The efficacy of these flame routes is guaranteed by the exact calculations and maintenance of their size.

Internal Component Isolation

All parts of the YBX5 motor that may cause a spark are sealed off from the outside world. The electrical connections, stator windings, and rotor are all part of this. The possibility of these parts setting fire to combustible materials is greatly reduced by housing them in the explosion-proof housing.

Thermal Management Systems

Motors with the YBX5 design have state-of-the-art thermal management technologies that keep the outside surface from overheating and setting fire to combustible materials. The surface temperature of the motor must remain below the ignition point of any nearby combustible materials, which may be achieved by the use of internal cooling fans, heat sinks, or specifically engineered cooling fins.

Comparing Operational Reliability and Downtime: YBX5 vs. Standard Motors in Refineries

Compared to regular motors, YBX5 explosion-proof motors provide substantial benefits in oil refineries in terms of operational dependability and downtime minimization. In the context of activities in a refinery, let's compare these two motor types.

Durability in Harsh Environments

Oil refineries are famously perilous places, and YBX5 engines are built to withstand the extraordinarily warm, destructive chemicals and maybe hazardous situations that laborers face day by day. In contrast to standard engines, which may break down quickly in such conditions, its strong design leads to fewer glitches and a longer working life.

Safety-Related Downtime

When utilized in possibly perilous situations, standard engines may need to be turned down frequently for assessments or other safety-related reasons. Due to its certification for use in hazardous areas, YBX5 engines enormously diminish the requirement for downtime connected to security, empowering more continuous operation.

Maintenance Requirements

Although YBX5 engines are more costly up front, they frequently require less upkeep than customary engines in refinery settings. Decreased wear and tear is a result of its fixed, tough structure, which avoids defilement of inner components. As a result, downtime will be diminished, and upkeep interventions will be less frequent.

Regulatory Compliance

Without the requirement for additional defensive measures, YBX5 engines ensure compliance with security rules for unsafe situations. Since of this, there will be no more downtime caused by administrative assessments or by the requirement to prepare normal engines with explosion-proof enclosures.

Long-Term Cost-Benefit Analysis of Deploying YBX5 Motors in Refinery Applications

There are substantial benefits to using YBX5 explosion-proof motors in refineries, despite the fact that they may cost more up front than regular motors.

Reduced Maintenance Costs

Because of its robust construction and improved protection, YBX5 motors need less maintenance. This leads to fewer breakdowns in maintenance, lower labor costs, and fewer replacement components needed.

Extended Operational Life

YBX5 motors are designed to withstand the harsh conditions in refineries, resulting in a longer operational life compared to standard motors. It saves a ton of money in the long term since motors live longer and don't need to be changed as frequently.

Improved Safety and Reduced Risk

The usage of YBX5 motors in hazardous areas significantly reduces the probability of fires and explosions. With this improved safety profile, insurance rates and costs associated with accidents and safety incidents might go down.

Energy Efficiency

Many YBX5 motors include energy-saving features that could lead to lower operating costs over time. The effect on energy consumption may be small for individual motors, but it adds up quickly when applied to the many motors present in a refinery.

Regulatory Compliance

Refineries may more easily satisfy safety regulations using YBX5 motors, which eliminate the need for further modifications or protective gear. As a result, you may be able to save money on regulatory compliance expenses and stay out of hot water if you don't comply.

Conclusion

Because of its sturdy construction, safety measures, and long-term operating advantages, YBX5 explosion-proof motors are the best option for oil refineries. Their longevity, low maintenance needs, and capacity to function safely in potentially dangerous conditions make them an economical choice for use in refineries. Refineries may reduce operating risks, boost dependability, and save money in the long run by switching to YBX5 motors.

FAQ

1. What makes YBX5 explosion-proof motors different from standard motors?

For use in potentially explosive settings, such as oil refineries, YBX5 explosion-proof motors are an ideal choice. Their flame routes, heat management systems, and sturdy enclosures prevent internal explosions from setting fire to combustible materials in the vicinity. These particular safety measures are not included in standard motors.

2. Are YBX5 explosion-proof motors more expensive than standard motors?

Although YBX5 motors are more expensive up front, they usually end up saving money in the end owing to their increased operating life, less maintenance needs, and improved safety measures that lessen the likelihood of downtime and possible dangers.

3. How often do YBX5 explosion-proof motors need to be maintained?

The sealed, sturdy design of YBX5 motors means they often need less maintenance than regular motors in refinery settings. Manufacturer guidelines and industry requirements for explosion-proof equipment should be followed when determining particular maintenance schedules, which in turn rely on operational circumstances.

Elevate Your Refinery's Safety and Efficiency with XCMOTOR's YBX5 Explosion-Proof Motors

XCMOTOR is your trusted partner for high-quality YBX5 explosion-proof motors. Our motors are engineered to meet the demanding requirements of oil refineries, ensuring safe and reliable operation in hazardous environments. With XCMOTOR, you benefit from our extensive experience, commitment to innovation, and dedication to customer satisfaction. Don't compromise on safety or performance - choose XCMOTOR for your refinery's motor needs. Contact us today at xcmotors@163.com to learn more about our YBX5 explosion-proof motor solutions and how we can support your specific requirements. XCMOTOR: Your reliable YBX5 explosion-proof motor supplier.

References

1. American Petroleum Institute. (2021). "Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities." API RP 500.

2. International Electrotechnical Commission. (2020). "Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures 'd'." IEC 60079-1.

3. National Fire Protection Association. (2020). "NFPA 70: National Electrical Code." Article 500: Hazardous (Classified) Locations.

4. Occupational Safety and Health Administration. (2019). "Oil and Gas Extraction - Standards and Enforcement." OSHA Technical Manual, Section IV: Chapter 2.

5. U.S. Chemical Safety and Hazard Investigation Board. (2018). "Refinery Incidents Investigation Report: Common Factors and Key Lessons."

6. Institute of Electrical and Electronics Engineers. (2021). "IEEE Standard for Petroleum and Chemical Industry—Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors—Up to and Including 370 kW." IEEE Std 841-2021.