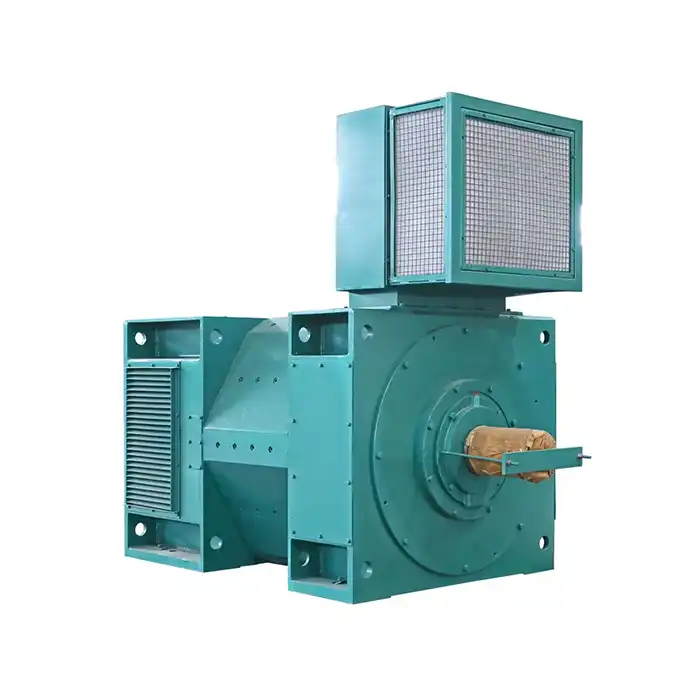

Exploring Explosion-proof Motor Designs

Explosion-proof mining motors are specifically engineered to minimize the risk of sparking in hazardous environments. These motors are crucial in mining operations where flammable gases or dust are present.

Enclosure Types for Explosion-proof Motors

Different enclosure types are used in explosion-proof motor designs to prevent sparks from escaping and igniting the surrounding atmosphere:

- Totally Enclosed Fan-Cooled (TEFC): TEFC motors are equipped with a fan mounted on the motor shaft, which circulates air over the motor’s surface, ensuring efficient cooling. This helps maintain optimal operating temperature and prevents overheating, which could lead to sparks and ignition in hazardous environments.

- Totally Enclosed Non-Ventilated (TENV): TENV motors do not include external fans. Instead, they rely on natural surface cooling to dissipate heat. The sealed design ensures that no dust or contaminants can enter the motor, making them ideal for clean environments where ventilation is limited or unavailable.

- Totally Enclosed Air Over (TEAO): TEAO motors are designed to be cooled by the air flowing over the motor's external surface. These motors are typically used in environments where ambient air or external forced airflow is available, offering effective cooling without the need for internal fans.

Materials Used in Explosion-proof Motors

The choice of materials is crucial in designing explosion-proof motors:

- Cast Iron: Provides excellent strength and heat dissipation.

- Aluminum: Offers lightweight properties and good heat conductivity.

- Stainless Steel: Resistant to corrosion and suitable for harsh environments.

Internal Design Features

Several internal design features contribute to spark reduction in explosion-proof motors:

- Flame Paths: Carefully designed paths prevent flame propagation.

- Increased Air Gaps: Larger air gaps between the rotor and stator reduce the risk of sparking.

- Enhanced Insulation: High-quality insulation materials prevent electrical breakdown.

Motor Maintenance Practices to Prevent Sparking in Mining Environments

Regular maintenance is essential to ensure the continued safe operation of mining motors and prevent sparking.

Regular Inspection and Cleaning

Routine inspections and cleaning help identify and address potential issues before they lead to sparking:

- Visual Inspections: Regular visual inspections are essential to identify early signs of wear, damage, or contamination. These checks help spot any loose components, cracks, or corrosion that could lead to malfunctioning or sparking. Detecting these issues early can prevent costly repairs and enhance safety.

- Cleaning Procedures: Routine cleaning procedures are crucial for removing dust, debris, and contaminants that can build up on the motor's surface or internal parts. Such buildup can cause overheating, wear, or even sparking, so maintaining a clean environment is key to preventing these risks.

- Thermal Imaging: Thermal imaging, using infrared cameras, allows for non-invasive detection of hot spots within the motor. These areas of excessive heat can signal potential electrical issues, such as insulation failure or friction, that may lead to sparking. Identifying these issues before they escalate ensures safer and more efficient motor operation.

Lubrication Management

Proper lubrication is crucial for reducing friction and preventing sparking:

- Lubricant Selection: Use of appropriate lubricants for the specific motor and operating conditions.

- Lubrication Schedule: Adherence to manufacturer-recommended lubrication intervals.

- Contamination Prevention: Implementation of measures to prevent lubricant contamination.

Bearing Maintenance

Well-maintained bearings are essential for smooth motor operation and spark prevention:

- Bearing Inspection: Regular checks for wear, damage, or misalignment.

- Bearing Replacement: Timely replacement of worn or damaged bearings.

- Vibration Monitoring: Use of vibration analysis to detect early signs of bearing issues.

Electrical Component Checks

Regular inspection and maintenance of electrical components help prevent sparking:

- Wiring Inspections: Checks for loose connections, frayed wires, or damaged insulation.

- Brush Maintenance: For motors with brushes, regular inspection and replacement as needed.

- Insulation Resistance Testing: Periodic testing to ensure insulation integrity.

Implementing Proper Grounding for Spark Reduction

Proper grounding is a critical aspect of reducing sparking in mining motors. It helps dissipate static electricity and prevents the buildup of electrical charges that could lead to sparking.

Grounding System Design

An effective grounding system is essential for spark reduction:

- Equipotential Bonding: Equipotential bonding involves ensuring that all metal parts of the system are at the same electrical potential, minimizing the risk of electrical shock or sparking. By connecting metal parts together, it helps maintain uniform voltage across the equipment, preventing dangerous potential differences that could lead to sparks.

- Low-Impedance Paths: Creating low-impedance paths ensures efficient current flow to ground, reducing the possibility of electrical faults causing sparks. A low-impedance path minimizes resistance, allowing the electrical current to safely discharge into the earth, preventing the buildup of dangerous electrical charges.

- Redundant Grounding: Implementing multiple grounding points enhances safety by providing backup paths for electrical discharge. Redundant grounding ensures that if one path fails, the system still has alternative routes to safely direct electrical currents away from sensitive equipment, reducing the risk of sparking and ensuring continuous protection.

Grounding Conductor Selection

Choosing the right grounding conductors is crucial for effective spark reduction:

- Conductor Size: Selecting appropriately sized conductors based on motor ratings.

- Material Selection: Using corrosion-resistant materials suitable for the mining environment.

- Connection Methods: Implementing reliable connection techniques for secure grounding.

Regular Grounding System Maintenance

Ongoing maintenance of the grounding system ensures its continued effectiveness:

- Resistance Testing: Periodic checks of ground resistance to ensure it remains within acceptable limits.

- Visual Inspections: Regular checks for corrosion, damage, or loose connections.

- Documentation: Maintaining records of grounding system tests and maintenance activities.

Static Electricity Management

Managing static electricity is crucial for preventing sparking in mining environments:

- Anti-static Materials: Use of anti-static materials in motor components and surrounding equipment.

- Humidity Control: Maintaining appropriate humidity levels to reduce static buildup.

- Static Discharge Devices: Implementation of devices to safely dissipate static charges.

Conclusion

Cutting down on sparking in mining motors is important for keeping processes safe in places that could be dangerous. By using motors that can't explode, doing regular upkeep, and making sure that everything is grounded properly, mining operations can greatly lower the risk of sparking and the dangers that come with it. To keep making mining activities safer and more efficient, it's important to keep up with the latest changes in motor technology and safety procedures.

Choose XCMOTOR for Reliable and Safe Mining Motors

XCMOTOR is a well-known and trusted mining motor manufacturer that lets you choose motors that put safety and performance first. Our explosion-proof motors are made with cutting-edge technologies that reduce sparks, making them the safest choice for dangerous mining settings. Because we care about quality and innovation, we make motors that not only meet but also exceed safety standards in the industry. For expert advice on selecting the right motor for your mining operations, contact our team at xcmotors@163.com. Choose XCMOTOR for peace of mind and uncompromised performance in your mining operations.

References

1. Smith, J. (2022). Advancements in Explosion-Proof Motor Design for Mining Applications. Journal of Mining Engineering, 45(3), 178-192.

2. Johnson, R., & Brown, T. (2021). Maintenance Strategies for Spark Reduction in Mining Motors. International Journal of Industrial Maintenance, 33(2), 89-104.

3. Garcia, M. et al. (2023). Grounding Systems in Hazardous Mining Environments: A Comprehensive Review. Mining Safety Technology, 28(4), 301-318.

4. Williams, E. (2022). Static Electricity Management in Underground Mining Operations. Journal of Electrostatic Hazards, 39(1), 55-70.

5. Lee, K., & Parker, S. (2021). Comparative Analysis of Explosion-Proof Motor Enclosures for Mining Applications. Mining Equipment and Electrotechnology, 50(2), 210-225.

6. Thompson, L. (2023). Innovations in Motor Insulation Materials for Spark Prevention in Mining. Journal of Mining Electrical Systems, 42(3), 145-160.